7.2: In-lab Exercises

- Page ID

- 47381

Optical Wave-Guides and Fibers

Basic Fiber Handling and Measurements

The objective of these experiments is to familiarize the student with techniques for handling fibers, coupling light into and extracting light from fibers, and basic fiber-optic measurement techniques.

7.1 Examination of Various Fiber Types and Fiber-Cabling Technologies

Take a look at the single-mode, multi-mode and plastic fibers in the laboratory. Pay particular attention to their construction and the size of the core/cladding structure of each fiber with the aid of the microscope. Also look at the various types of connectors and connectorized fibers. Postulate as to the use of the various cabling members and applications for particular connector types.

7.2 Cleaving, Cleaning, Furcating, Connectorizing and Splicing Fiber

Because most optical fiber is very thin and very fragile, fibers can be difficult to use unless they are placed in a positioning ferule or connectorized or both. Positioning ferules and connectors allow a fiber to be coupled to a photo-detector or a light source. Splicing joins two fibers, sometimes through the use of connectors. All three operations involve stripping, cleaving, and cleaning at some stage (or several stages) of the process.

Basic Procedures for Stripping Fiber

"Bare" fiber is actually composed of three layers of material: the core, the cladding, and a protective buffer. The buffer is analogous to the plastic jacket on conductive wires. At any junction in the fiber (i.e., any point at which the fiber will be spliced or connected), the buffer must be removed. We use one of four tools to strip fiber in the lab. In each case, the buffer is stripped no more than a centimeter at a time.

- Wire strippers: Operate the wire strippers just as you would use them to strip wire, while making sure that you do not stress the fiber (by pulling or bending) enough to crack the glass. Glass fiber is quite resilient to longitudinal strain, having a high tensile strength; however, glass fiber will easily snap when shearing stresses or bending (impact) stresses are applied.

- No-Nicks Fiber Stripper: Assure that there is no residue in the blades of this stripper. Place the fiber between the triangular teeth of the tool with the fiber end in the direction of the arrow on the tool head. GENTLY release the grips and allow the head to close, ensuring that the fiber remains in place. Pull the tool head in the direction of the arrow to strip the jacket.

- Fiber stripping tool: Assure that there is no residue in the blades of the stripper. Insert the fiber into the alignment hole at the front of the stripper until the end lines up at the desired point on the stripper scale (on the tool's handle). Squeeze the handles fully together and pull along the fiber axis.

- Chemical strippers: On rare occasions you may need to use a chemical stripper as to not damage the cladding of the fiber. To do this, you will use paint thinner. By dipping the fiber in paint thinner for a period of 5 minutes, you will dissolve the fiber buffer. After dipping, any excess residue can be removed easily with a damp Kim wipe – be sure to avoid skin-contact with the paint thinner. We prefer not to use this method since paint thinner is toxic and creates strong fumes within the laboratory. Also, additional measures must be taken to dispose of old or used paint thinner with the environmental protection office at MIT.

Basic Procedures for Cleaning Fiber

Once the jacket has been stripped from a fiber, it is necessary to clean any remaining residue from the cladding. Simply fold a small Kim wipe into eighths and wet it with alcohol. Fold the wipe again, and insert the fiber into the "channel." Apply gentle pressure and pull the wipe toward the end of the fiber. Repeat until the fiber feels smooth while dragging the wipe.

Basic Procedure for Cleaving Fiber

The ends of a fiber must have flat surfaces (i.e., perpendicular to the fiber axis) to allow a good connection. Cleaving allows the precise termination of the end of a fiber. It always involves a process of first scoring the fiber and then breaking the glass along the scored line. We use two tools for cleaving in the lab:

- Cleaving with the scribe: The scribe is a diamond-tipped tool that can be used to score the fiber. The first step while using the scribe is to secure the end of the fiber to the lab table. A lab partner or a piece of tape comes in handy for this exercise. Then, while pulling the fiber taut, gently drag the scribe tip across the fiber, perpendicular to its axis. Place a drop of water on the scribed region of the fiber to facilitate the cleave. Finally, while applying pressure to the secured fiber end, pull the fiber straight back until it cleaves.

- Cleaving with a fiber-cleaving tool: For a more accurate cleave, the T&B cleave tool should be used. Adjust the knob on the tool's side until the scale reflects the amount of stripped fiber that will remain. Then, insert the fiber into the screw end of the tool until it stops. Assure that the fiber exits at the gripping end of the tool. Close the latch at the screw end and squeeze the gripping end of the tool. Pull down the safety latch, and squeeze the scribe block. Release the scribe block. Pull the gripping end away from the scribe block to cleave the fiber.

Typically, the fiber is inspected after the cleaving process. The cleaved end should be flat across the fiber and perpendicular to its axis. There should be no tag protruding from the fiber, and the initial scribe should be less than 5% of the core diameter.

Basic Procedure for Connectorizing Fiber

Connectorizing gives a fiber a protected, polished end that is much more versatile and stable than an ordinary bare fiber. The operation for fiber connectorization with the _____ connector is as follows:

- Clean the connectors that will be used. Any dust or broken fiber ends in the connector will make it difficult to apply glue to the fiber. Thus, soak the connector in isopropyl alcohol for a few minutes. Shake out any excess, and allow the remaining alcohol to evaporate. Inspect the ferrule (white ceramic tube) of the connector by holding it up to a light. Light should be visible through the connector body 30cm to 45cm from your eye. Occasionally, if the connector has been used before, a fiber end may be stuck in the capillary (hole) of the ferule. If this is the case, use a small piece of piano wire to push the glass through the ferule, and wipe and soak the connector.

- Cut the furcation tubing to a length 3cm longer than the desired length. Use the Kevlar scissors to cut through the yellow strands.

- Slide the strain relief boots and crimp sleeves onto the tubing.

- Cut the outer tubing ~1.5cm from the end, leaving the Kevlar strands and any inner tubing intact.

- Insert the fiber into the inner tubing and push through until the end of the fiber comes out the end of the tubing. Allow ~2.5cm of extra fiber on each end of the tubing.

- Strip ~1.5cm of jacket from the fiber ends to be connectorized, and clean the fiber with isopropyl alcohol.

- Carefully test fit the connector onto the stripped fiber end. Slowly rotate the connector to ease the fiber's entry into the ferule. Pay close attention to the fiber: if it is bending under pressure, it is not entering the ferule tip. Pull back, and attempt to find the capillary. Once the fiber end comes out the ferule tip, continue to feed it through until it stops. Assure that at least 2.5mm of fiber exits the tip. Once the fit has been tested, remove the connector.

- Prepare the epoxy packet by removing the separator bar and mixing the two components. Thread a needle onto the syringe, and remove the plunger. Remove the corner of the epoxy packet and fill the syringe with the contents. Invert the syringe, insert the plunger, and wait for the epoxy to clear from the syringe tip. Then, press the plunger to expel air from the tip. If necessary, tap the tip of the syringe to flush any air bubbles from the epoxy. (Air bubbles remaining in the cured epoxy will weaken the bond between the connector and the fiber.) Wipe any excess epoxy from the syringe needle.

- Insert the needle into the back of the connector until it bottoms out. Maintain pressure between the connector and the needle, and press the plunger of the syringe to inject epoxy into the ferule. Continue applying epoxy until a small bead appears on the outside face of the connector ferrule. Remove the needle.

- Insert the fiber into the connector as before. Assure that the epoxy bead still remains to support the fiber. If the bead has diminished, it is possible to add epoxy directly to the connector tip.

- Seat the connector. Slide the crimp ring over the end of the connector.

- Using the 0.178" hex section of the crimp tool die, crimp the sleeve onto the connector. Then, using the 0.128” hex section, crimp the sleeve to the fiber furcation tubing.

- Apply some epoxy to the inside of the strain relief boot, and slide it into place ensuring that the connector ring can still turn as necessary. Allow the epoxy to cure. Note: Curing can be accomplished by heating the connectors at 65 0 C for 15 minutes and cooling for 15 minutes. Otherwise, allow the connectors to cure overnight.

Polishing Fiber Connectors

The final step in connectorizing a fiber is polishing. Polishing ensures that the fiber and ferule tip is flat, smooth and clean.

- Using a fiber scribe, score the fiber just above the epoxy bead, and cleave it. Ideally, the remaining fiber tip should extend no more than one fiber diameter above the epoxy bead.

- Take a 1"x9" strip of a 5-micron lapping sheet and fold it in half without creasing the film. Gently polish the fiber tip until it is flush with the epoxy bead.

- Clean the rubber polishing pad with isopropyl alcohol and a Kimwipe. Apply a 5-micron lapping sheet to the pad, rough side up.

- Clean the polishing disc and the connector with isopropyl alcohol and a Kimwipe. Place the polishing disc on the lapping sheet. Gently place the connector in the hole of the disc.

- Without applying pressure downward on the connector, begin polishing the fiber in a figure-8 pattern. If the fiber is contacting the lapping sheet, a light figure 8 pattern should appear on the polishing film. If no pattern appears, apply gentle pressure on the connector. Increase the pressure gradually as the epoxy bead is polished down. Inspect the connector end frequently, and continue polishing until a thin film of epoxy remains.

- Repeat steps 3, 4, and 5 with the 3-micron lapping sheet until only a faint hint of epoxy remains on the connector end.

- Repeat steps 3, 4, and 5 with the 1-micron lapping sheet, applying 3 to 4 drops of water on the polishing film. Continue until no epoxy remains on the connector.

- Inspect the fiber tip with the fiber microscope. If necessary, clean the 1-micron sheet and polish the tip again.

- Polish the tip with the 0.3-micron lapping sheet, once again using 3 to 4 drops of water.

- Inspect the fiber tip for the following:

- The connector end surface should be free of epoxy.

- The fiber should be flush with the end of the connector ferule.

- There should be no heavy scratches through the core of the fiber.

- There may be light random scratches, but there should not be any chips in the edges of the fiber.

Whenever using connectorized fiber, make sure that the ends are clean. Use isopropyl alcohol and a Kimwipe to make sure the surface is dust and oil free.

7.3 Estimation of Numerical Aperture (NA) of a Multimode Fiber.

The numerical aperture of a fiber is defined as the sine of the maximum acceptance half angle of the fiber. In order to get a reasonable measurement of numerical aperture it may be necessary to first perform mode stripping on the fiber, especially if a short length of fiber is being used. Secondly, the output end of the fiber must be polished or cleaved so it is flat. Thirdly, the fiber must be overfilled with light. This is, the cone angle of the light coupled into the core of the fiber must exceed the acceptance angle of the fiber – we can do this through the use of a high-power microscope objective.

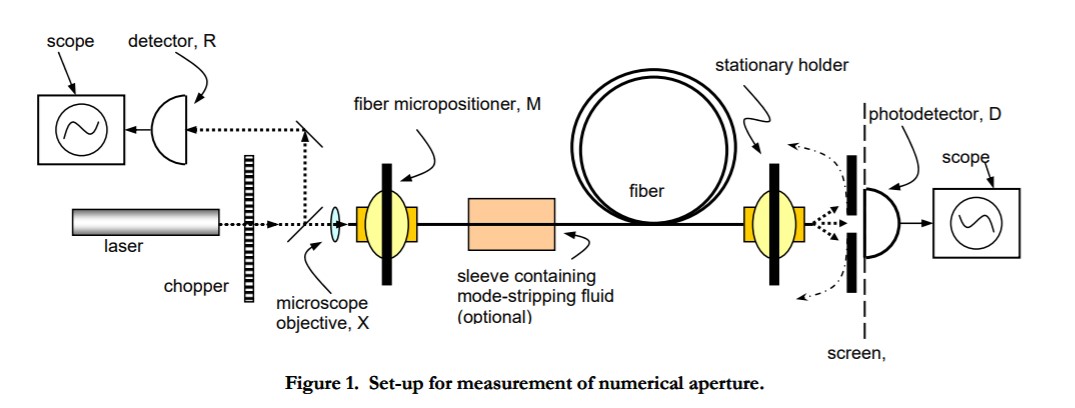

The setup for the measurement of numerical aperture of a multimode fiber is shown in Fig. 1. In this system, since fluctuations in the laser light can affect the measurement, a fraction of the light from the He-Ne laser can be split off using the beam splitter and monitored on a reference detector R. The major portion of the light is transmitted through the beam splitter and coupled into the fiber with the aid of a microscope objective X and a fiber micropositioner M. The output light from the end of the fiber, which is held stationary, can be viewed on a screen S or a photodetector D which sits on a rotation stage calibrated in degrees. To get rid of higher-order modes traveling in the cladding, we could use a sleeve that surrounds the cladding with mode-stripping fluid (see Fig. 1) – however omitting this device will not significantly affect the results for this exercise.

First make a visual observation of the numerical aperture by placing the small white screen a few centimeters away from the output end of the fiber and observing the size of the spot on the screen. By making rough measurements of the spot diameter and the distance between the end of the fiber and the screen, a crude estimate of the numerical aperture can be obtained.

- For a more precise measurement of the numerical aperture the detector and the calibrated rotating stage are used. The end of the fiber is secured to a post a few centimeters above the axis of rotation of the table and at the same level as the detector. With the fiber stationary, the base of the stage is rotated so the detector sweeps out an arc around the end of the fiber. Measurements of the detector power should be made every two degrees along with the corresponding value on the reference detector.

The ratio of the output light intensity to the reference light intensity should then be plotted as a function of angle, and the numerical aperture determined from the plot. These curves could be repeated for launch conditions corresponding to an underfilled condition to show that, in this case, the measured result underestimates the numerical aperture of the fiber. Record the data and calculate the NA in your laboratory notebook.

Note on mode stripping.

Mode stripping is the process of removing high-order modes propagating in the cladding of a fiber. Mode stripping is often necessary when making measurements on fibers to avoid erroneous results. Such is the case for the numerical aperture measurement in Fig. 1 above. Mode strippers are generally placed near the input and output ends of a fiber, so that those highorder cladding modes which result from overfilling at the input end are removed along with loworder modes that convert to high-order modes in the cladding because of scattering along the length of the fiber. For a bare glass fiber mode stripping can be accomplished by passing the fiber through a sleeve filled with honey, glycerin or mode-stripping index-matching fluid, which provides an approximate index match with the cladding.

- Using the fiber manipulator and the microscope objective, couple light from the laser into one of the fibers and perform mode stripping near the input end using the honey or glycerin jacket as shown in Fig. 1. Observe the evanescent losses through the honey or glycerin.

- Bend the fiber and observe the decrease in output signal on the scope as well as the light leakage from the fiber (a high curvature will be needed, but please do not break the fiber).

7.4 Mode-Distribution and Polarization Properties of Single-Mode Fibers

Observation of modes in a single-mode fiber

Couple the He-Ne laser beam into the single-mode (Coreguide or SMF-28) fiber and observe the mode patterns of the few low-order modes. Note that the fiber is not single mode at the He-Ne laser wavelength of 633 nm. To get a clean pattern, the ends of the fiber must be terminated properly. Sketch the patterns you see in your notebook – then identify which modes you have drawn (they might be composite modes – mixtures of more than one type of mode pattern).

Observe the polarization characteristics of these low-order modes by placing a polarizer in the path of the output beams. Write your observations in your laboratory notebook.

Polarization properties of single-mode fiber

In general, when an optical fiber is excited with linearly polarized light, the light exiting the fiber is no longer linearly polarized. By twisting a single-mode fiber with a rotation about the fiber axis, it is possible to alter the polarization state of the light in the region of the twist because strain-induced birefringence in the glass.

The “rabbit ears,” a type of polarization controller, are designed to apply such a twist to the fiber. Using this apparatus in conjunction with two linear polarizers, apply a twist to the fiber and monitor the polarization state of the light exiting the fiber. Try to obtain a linearly polarized output beam without breaking the fiber.

7.5 Observation of Bending and Splicing-Misalignment Losses (optional)

Couple He-Ne laser light into the multi-mode fiber that is threaded through the “rabbit-ears”, and observe the leakage of light out of the fiber especially in the small radial bend on the inner loop of the “rabbit-ears”. Write your observations in your lab notebook.

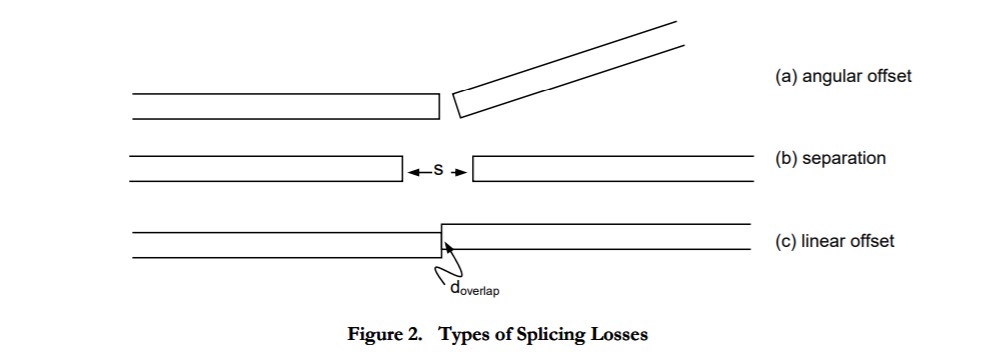

Next couple the light from the output of this fiber into a second fiber by but coupling the ends of the two fibers. Observe the output of the second fiber on a screen. Investigate the coupling losses for axial offset, angular offset and separation as illustrated below.

Now, determine the loss in decibels incurred by connecting two FC-PC-type connectors together. Do the same for the loss incurred by using a fiber splice. Which technique for connecting two length of fiber together is better? Why? What determines if one method is for connecting two fiber lengths together is ‘better’ than another?

7.6 Fiber Attenuation Coefficient of Inter-Office Multimode Plastic Fiber Cables (Optional)

For this equipment (cable substitution method) you will use the following equipment:

- ) FOTEC "S" consisting of a variable frequency pulse generator driving an LED at 665mm or similar connectorized pulsed source.

- FOTEC "C" optical power meter

- Oscilloscope

- Three lengths of plastic fiber l1, (short) and l2 (long), and an unknown length l3.

- Connect the FOTEC "S" to the FOTEC "C" with a short length of cable. Observe, using the dual trace oscilloscope, the internal electrical drive signal to the FOTEC "S" LED, and the output of the FOTEC "C" detector by connecting the outputs of both these instruments to the oscilloscope. What is the frequency range of the FOTEC "S"?

- Choose a reasonable operating frequency for the pair of instruments (for good optical power measurements) and use the cable substitution method described in the notes to measure the attenuation coefficient of the cables.

- Insert an unknown length l3 of cable, and measure the power transmitted through the unknown length. Use this result and the attenuation coefficient of the fiber to estimate the length l3.

- Comment on the practical limitations of the above method of measuring attenuation coefficient.

7.7 Imaging Pr Imaging Properties of operties of a Coherent Guided-Wa a Coherent Guided-Wave Bundle

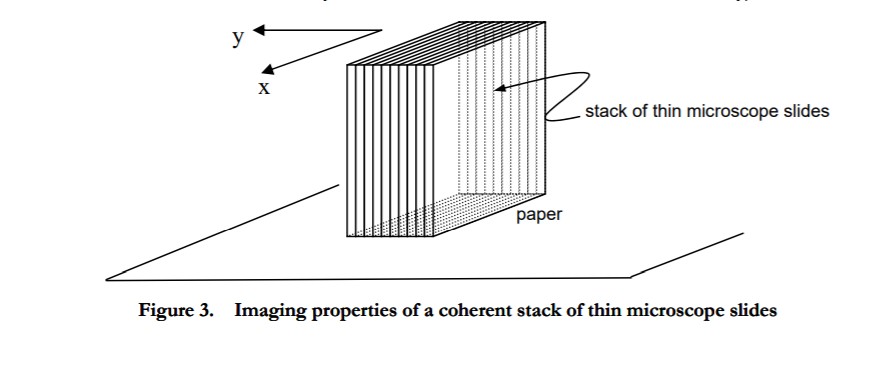

A stack of thin cover glass slides has been provided (see Fig. 3). Observe the imaging properties of this stack by using it to read text on a printed page. For example, what do you see when you move your head back and forth in the x direction? In the y direction? Why? Explain its principles of operation. How does this compare to what you would see had you used a solid block of glass with the same shape? Or bundle of optical fibers with the same shape? Why?

Also provided is a naturally-occurring rock (Ulexite), which has waveguiding properties. Repeat the above experiment with the Ulexite sample. Observe the crisp high-resolution imaging properties of the rock. Postulate as to how the rock works (you may also do some outside research to find out how this rock is created in nature – or how synthetic versions are created in the laboratory).

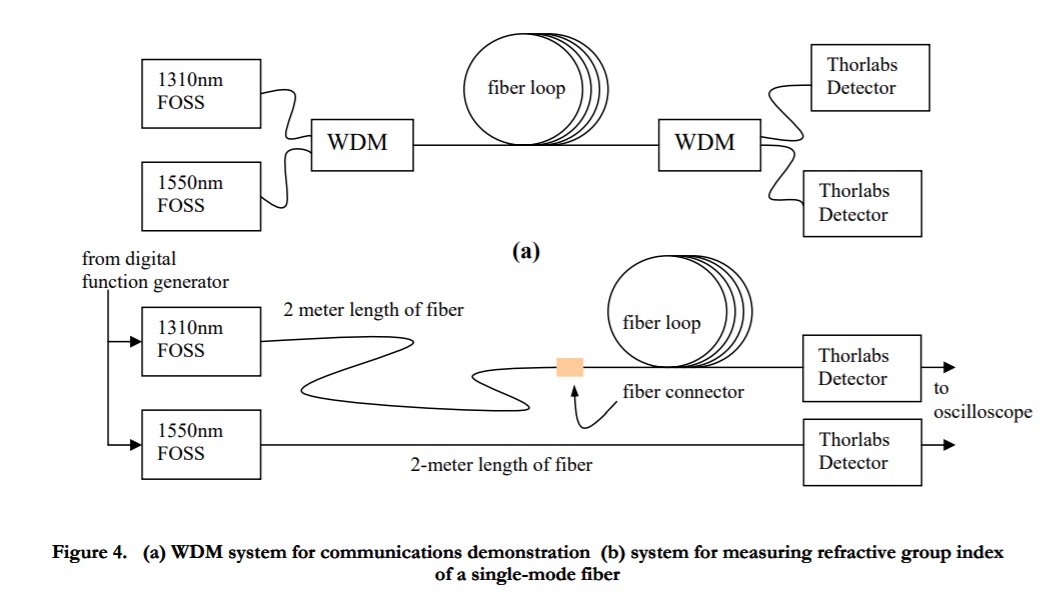

7.8 Wavelength Multiplexing Wavelength Multiplexing, Group Index and Dispersion

In this experiment, (see Fig. 4) you are given two Fiber Optic Stable Sources (FOSSs), each of which is internally or externally modulatable. One of the sources operates at a wavelength of 1310nm and the other operates at 1550 nm. You are also provided with two loops of connectorized fiber, and several FC-connectorized patch cables, all with an effective group index of n = 1.468. Additionally, you are given two Newport benchtop Wavelength Division Multiplexers (WDMs) and two Thorlabs high-speed InGaAs fiber optic photodetectors. You are also provided with a digital signal generator, numerous equal-lengths of BNC cable, and an oscilloscope.

Here the goal is to generate two optical signals, both infrared, and then wavelength division multiplex them into an optical fiber. Both signals will carry a digital waveform. At the output end of the fiber the signals are to be demultiplexed and separated, and the input signals recovered.

- Try to measure the signal to noise ratio of the system, as determined by the cross-talk between the two input optical signals at the output of the system. Modulate the sources with their internal frequency driver circuitry and view the detector output on the oscilloscope.

- By modulating one of the sources with a high-frequency external digital waveform, determine the length of the 900 mm furcated spool. Make sure the input modulation signal goes no higher than 4 volts peak-to-peak or you will destroy the fiber optic source!

- Now, given that the un-furcated fiber spool has a length of 100 meters, determine the group index, n, for that fiber.

- Operating with both sources at a high external modulation rate, and with both fiber spools connected between the WDMs, can you determine the difference in arrival times between the 1310nm and 1550 nm light? Does this correlate what you have learned about dispersion in step-index single-mode optical fibers?

7.9 Pulse Broadening (optional)

Here the goal is to make a qualitative measurement of multimode pulse broadening as a function of fiber length and numerical aperture and fiber type.

- Compare the pulse shape from the short fiber used earlier in the cable substitution experiment (7.6) with the shape after propagating through one of the long fibers. With the long length of fiber, change the microscope objective illuminating the fiber from low power to high power (to change the numerical aperture) and re-observe the pulse shape.

- Compare the broadening in a step index fiber with the broadening in a graded fiber of approximately the same length, keeping the numerical aperture constant.

II. FIBER OPTIC SENSORS AND SYSTEMS (possible projects)

The goal of these projects is to familiarize students with various fiber-optic sensor technologies.

7.10 WDM Video-Rate Transmission System

You have already observed the WDM system in the previous part of this laboratory exercise. However, you will now look at it in terms of a communication system. You are given two modulator circuits used to convert the analog video input into a serial digital output. These signals are transmitted over a length of fiber optic cable by use of a WDM. The signals are then recovered and converted to an analog signal to be displayed on side-by-side video monitors.

7.11 Sagnac Fiber-Optic Gyroscope

7.12 Fiber-Optic Refractometer

7.13 Fiber-Optic Thermometer

7.14 Fiber-Optic Velocimeter

7.15 Fiber-Optic Endoscope