7.3: Devices Involving Stimulated Emission

- Page ID

- 18981

Introduction

Lasers are devices that produce optical energy through stimulated emission and involve optical feedback. The word laser is an acronym for Light Amplification by Stimulated Emission of Radiation. Lasers come in a wide range of sizes and shapes. Some lasers produce continuous output power, denoted cw for continuous wave, and other lasers operate pulsed. One advantage of pulsed operation is that the peak intensity of the light produced can be extremely high even with moderate average input power. Some lasers are designed to operate at room temperature while other lasers require external cooling.

The development of many energy conversion devices required technological breakthroughs. The development of lasers, however, was preceded by breakthroughs in understanding of energy conversion processes in atoms and molecules. The idea of amplification by stimulated emission was first developed in the mid 1950s, [31, p. 183] [83, p. 687]. A maser, which operated at microwave frequencies, was demonstrated only a few years later by Gordon, Zeiger, and Townes in around 1955 [83, p. 687]. In 1960, a ruby laser with visible output at \(\lambda = 694 nm\) was demonstrated by Maiman, [83, p. 687]. Lasing in semiconductors was predicted in 1961 [92] and demonstrated within a year in gallium arsenide [93]. The development of semiconductor lasers required both the theoretical prediction as well as development in the ability to deposit pure thin semiconductor layers. Thin crystalline layers grown on top of a substrate are called epitaxial layers. Early semiconductor lasers were made by growing epitaxial layers from a liquid melt, through a process called liquid phase epitaxy [94]. In subsequent years, other methods which allowed more control and precision were developed including molecular beam epitaxy [95] and metal organic chemical vapor deposition [96].

Laser Components

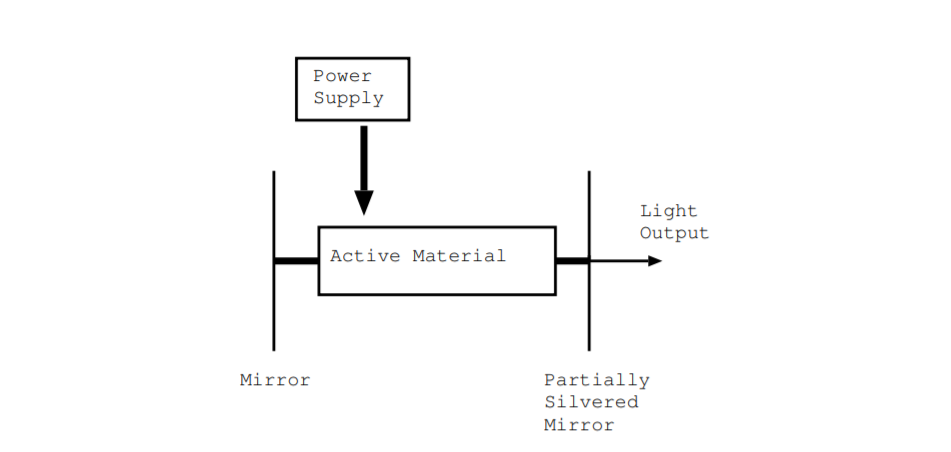

Lasers have three main components: a power supply also called a pump, an active material, and a cavity. These components are illustrated in Fig. \(\PageIndex{1}\) where mirrors form the cavity. Input energy from the power supply excites electrons or molecules in the active material. A photon interacts with the excited electrons or molecules of the active material stimulating the emission of a photon at the same frequency, phase, direction, and electromagnetic polarization. The cavity reflects the photon back to the active material so that it can stimulate another photon, and this process continues to occur as these photons stimulate additional identical photons.

Pumps

Laser power supplies are called pumps. Energy may be supplied to lasers in dierent ways. For many lasers, energy is supplied electrically. For example, the pump of a semiconductor laser is typically a battery which supplies a DC current. These lasers are energy conversion devices which convert the input electricity to light. For other lasers, energy is supplied optically, so the pump is a lamp or another laser. These lasers are energy conversion devices which convert light with large energy per photon to light with smaller energy per photon. The power supply of early ruby lasers were flashlamps [86, p. 351]. As another example, argon ion lasers are used to pump titanium doped sapphire lasers. Argon ion lasers can be tuned to emit photons with energy 2.54 eV (\(\lambda = 488 nm\)). These photons excite electrons in titanium doped sapphire. Titanium doped sapphire lasers are tunable solid state lasers which emit near infrared light [86, p. 392].

Active Materials

Active materials can be solids, liquids, or gases, and lasers can be classied based on the state of matter of the active material. The active material of a laser has multiple allowed energy levels, and energy conversion occurs as the active material transits between energy levels. When an electron transits between energy levels, its internal momentum changes, not its spatial position. Typically, the pump excites an electron from a lower to higher allowed energy level, and a photon is emitted when the electron goes from a higher to lower energy level. In some lasers such as carbon dioxide lasers, however, molecular vibration states are involved instead of electron energy states.

Optical amplification and lasing can only occur when there is a population inversion in the active material. The term population inversion means that more electrons are in the upper energy level than the lower energy level. The condition for a population inversion was defined by Equation 7.1.19. A photon begins the process of stimulated emission, and another photon is produced in the process. Only in the case of a population inversion can the resulting photon be more likely to stimulate another photon than decay by spontaneous emission, by emitting phonons, or by other means.

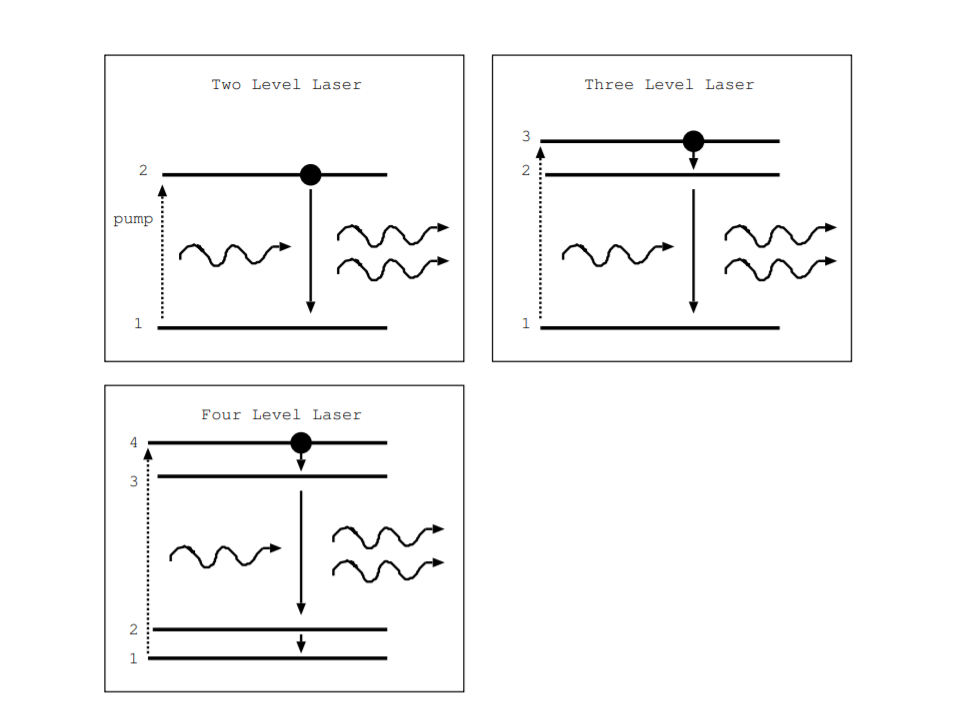

In some lasers, called two level lasers, the pump excites an electron from a lower energy level to a higher energy level, and lasing occurs as the electron transits back and forth between the same two levels. In other lasers, more energy levels must be considered. Figure \(\PageIndex{2}\) illustrates possible electron transitions in two, three, and four level lasers, but other three and four level schemes are possible too. In the three level system illustrated in the figure, the pump excites electrons from level one to level three. The electrons quickly decay to level two, possibly emitting heat, and lasing occurs as electrons transit from level two to level one. In the four level scheme illustrated, the pump excites electrons from level one to four. The electrons quickly decay from level four to three, emitting heat in the process. Lasing occurs between energy levels three and two. The electrons then decay between levels two and one, again emitting heat, vibration, or some other form of energy. Some four level systems lase more easily than two level systems because a population inversion may be easier to achieve in four than two level systems. Lasing requires a population inversion, and level two may be less likely to be occupied than level one.

Cavities

Laser cavities have two main functions. They confine photons to the active material and they act as optical filters. The simplest optical cavity is made from two mirrors as shown in Fig. \(\PageIndex{1}\). This type of cavity is called a Fabry Perot cavity. More complicated cavities have multiple mirrors, lenses, and other optical components to focus the desired photons within the active material and reject photons at frequencies other than the desired frequency. Semiconductor lasers do not use separate mirrors to form the cavity. In some semiconductor lasers, the edges of the semiconductors act as mirrors because the index of refraction of the semiconductor is larger than that of the surrounding air thereby reflecting a portion of the light back inside the semiconductor. The edges of these lasers are formed by cleaving along crystal planes to produce extremely flat surfaces. In other semiconductor lasers, multiple thin layers of material act as mirrors.

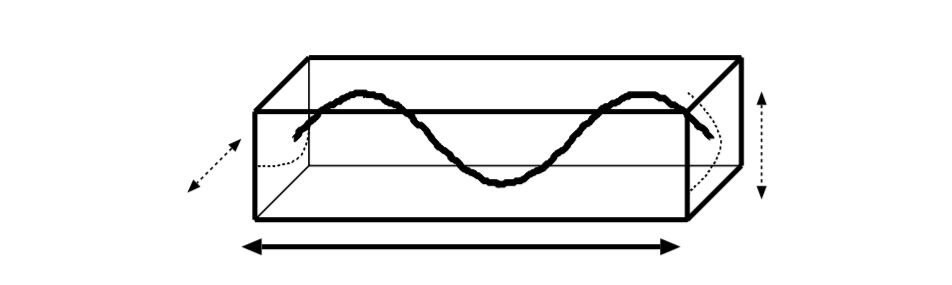

Even without an active material present, an optical cavity acts as an optical filter that selectively passes or rejects light of different wavelengths. To understand this idea, consider the rectangular cavity shown in Fig. \(\PageIndex{3}\). Assume that the cavity has partial mirrors on the left and right side so that some light can enter the cavity on the left side and some light can exit the cavity on the right. The direction along the length of the cavity, illustrated by the solid arrow, is called the longitudinal direction. The other two directions, illustrated by dotted arrows, are called transverse directions. If the longitudinal length of the cavity is exactly equal to an integer number of half wavelengths of the light, the wave will constructively interfere with itself. However, if the longitudinal length of the cavity is not equal to an integer number of half wavelengths, it will destructively interfere. The same ideas apply in the transverse directions. In the figure, the longitudinal length of the cavity is equal to three half wavelengths shown by the solid sinusoid. The transverse lengths are both equal to one half wavelength shown by the dotted sinusoids. Because of this constructive or destructive interference, cavities selectively allow certain wavelengths of light to pass through while they attenuate other wavelengths of light. In a typical laser cavity, the ratio of the longitudinal length to the transverse lengths is much larger than is shown in Fig. \(\PageIndex{3}\). Figure \(\PageIndex{3}\) illustrates a rectangular cavity while many lasers have cylindrical cavities instead. The same ideas apply, so only certain allowed longitudinal and transverse modes propagate in cylindrical cavities too [86, p. 133,145].

If there is a pump and an active material in a cavity, this filtering effect encourages lasing to occur at specific wavelengths due to the feedback the cavity provides. As discussed above, stimulated emission occurs when a photon interacts with an excited electron. The result is another photon of the same frequency, electromagnetic polarization, phase, and direction as the original photon. When the pump first turns on, electrons are excited, but no photons are present. Very soon, some photons are produced by spontaneous emission. Some of these photons stimulate the emission of additional photons. Since the cavity selectively attenuates some wavelengths but not others, photons produced by stimulated emission are more likely to occur at certain wavelengths corresponding to modes in the longitudinal direction. For these modes, the cavity length is equal to an integer multiple of half wavelengths. Due to the feedback of the laser cavity, these photons go on to stimulate additional identical photons. For this reason, the output of a laser necessarily has a very narrow wavelength range.

Laser Efficiency

The overall efficiency of a laser is the ratio of the output optical power over the input power. Many lasers are electrically pumped, and the overall efficiency, also known as the wall plug efficiency, for these lasers is the ratio of the output optical power over the input electrical power [10, p. 604].

\[\eta_{ef \, f} = \frac{P_{optical \; out}}{P_{electrical \; in}} \label{7.3.1} \]

The pump, active material, and cavity all affect a laser's efficiency. The overall efficiency is the product of a component due to the pump \(\eta_{pump}\), a component due to the active material \(\eta_{quantum}\), and a component due to the cavity \(\eta_{cavity}\) [86].

\[\eta_{ef \, f} = \eta_{pump} \cdot \eta_{quantum} \cdot \eta_{cavity} \nonumber \]

These factors vary widely from one type of laser to another.

In an optically pumped laser, a lamp or another laser excites the electrons of the active material. In this case, some of the pump light may get reflected from the surface or transmitted through instead of absorbed by the active material. Also, some of the pump energy may be converted directly to heat. Additionally, especially in the case of lamps which emit light over a wide range of frequencies, the pump light may have too little energy per photon to excite the electrons, or the light may have too much energy per photon thereby exciting electrons to a different upper energy level. Also, some of the pump light may interact with electrons that are already in excited energy states. In an electrically pumped laser, electricity excites the electrons of the active material. Some of the electrical energy may be converted to heat instead of exciting the electrons. All of these factors involving the pump contribute to \(\eta_{pump}\) and the overall laser efficiency \(\eta_{ef \, f}\).

The contribution to the overall laser efficiency due to the active material \(\eta_{quantum}\) is more commonly known as the internal quantum efficiency. Some fraction of excited electrons decay to a lower energy level and emit a photon by spontaneous or stimulated emission. Alternatively, other excited electrons decay to a lower energy level while emitting heat or lattice vibrations instead. The internal quantum efficiency is the ratio of the rate with which excited electrons decay and produce a photon over the rate at which all excited electrons decay [10, p. 562]. It depends on temperature, the concentration of impurities or crystalline defects, and other factors [10, p. 596].

Efficiency is also determined by the laser cavity. A laser cavity reflects photons towards the active material. However, the laser cavity must let some light exit. In many lasers, the cavity is formed by mirrors. While these mirrors reflect most of the light, some light is absorbed and some light is transmitted through the mirrors as laser output. Many lasers which use mirrors include lenses, prisms, and other optical components in the cavity to focus or filter light to the active material. These components may also reflect or absorb some light and thereby decrease the laser efficiency. As mentioned above, the cavity of many semiconductor lasers is formed by the interface between the active material and the surrounding air. While external mirrors can reflect over 99% of photons [86, p. 159], mirrors formed by semiconductor air interfaces are much less efficient. The amount of light reflected depends on the index of refraction of the material. In gallium arsenide, for example, the index of refraction is 3.52 which corresponds to only 31% of light reflected at each interface [97].

The influence on efficiency of internal absorption and mirror reflectivity can be summarized in a single relationship [98].

\[\eta_{e f f}=\eta_{e f f-o t h e r} \frac{\ln \left(\frac{1}{R}\right)}{\alpha l+\ln \left(\frac{1}{R}\right)} \label{7.3.3} \]

In this equation, \(R\) is the unitless mirror reflectivity, \(\alpha\) is the absorption coefficient of the active material in units \(m^{-1}\), and \(l\) is the length of the active material in \(m\). The term \(\eta_{ef \, f−other}\) represents the efficiency due to all other factors besides absorption and mirror reflectivity, and \(\eta_{ef \, f}\) is the overall efficiency. Equation \ref{7.3.1} can be rewritten with some algebra.

\[\eta_{e f f}=\eta_{e f f-o t h e r}\left(1-\frac{1}{1+\frac{1}{\alpha l} \ln \left(\frac{1}{R}\right)}\right) \nonumber \]

These efficiency concepts generalize to other energy conversion devices which produce light. Equation \ref{7.3.3} also describes the overall efficiency of LEDs and lamps in addition to electrically pumped lasers. The concepts of efficiency due to the pump and internal quantum efficiency also apply to LEDs and lamps. However, \(\eta_{cavity}\) is not useful in describing these devices because LEDs and lamps do not contain a cavity.

Laser Bandwidth

Compared to LEDs and gas discharge lamps, incandescent lamps emit light over a much wider range of wavelengths. Compared to these devices, lasers emit light over a much narrower range of wavelengths. One reason that lasers emit over such a narrow wavelength range is that photons generated by stimulated emission have the same wavelength as the stimulating photon. As explained above, another reason is that only light at integer half multiples of the length of an optical cavity constructively interfere.

This narrow bandwidth of lasers compared to other sources of light is a major advantage in many applications. For example, lasers generate communication signals sent down optical fibers. Multiple signals can simultaneously be sent down a single fiber with each signal produced by a laser at a slightly different frequency. Due to the narrow bandwidth, these signals can be separately detected at the receiver.

Bandwidth of devices which emit light is typically specified by the full width half maximum bandwidth (FWHM). More specifically, intensity of light emitted is plotted as a function of wavelength where optical intensity is proportional to the square of the electric field. To find the FWHM, identify the wavelength of maximum intensity, and identify the wavelengths corresponding to half this intensity. The wavelength difference between these points of half intensity is called the FWHM, and this quantity is specified in meters or more likely nanometers. Sometimes FWHM is specified in units of Hz instead. A frequency response plot, showing intensity of light emitted versus frequency, is used to find FWHM in Hz. Again two points at half maximum intensity are identified on the plot. The frequency difference between these points of half intensity is the FWHM in Hz. A related measure is called the quality factor, and lasers with narrow bandwidth have high quality factor. It is defined as the ratio of the wavelength in nm of peak intensity emitted over the FWHM in nm. Alternatively, it is defined as the ratio of the frequency of peak intensity over the FWHM in Hz.

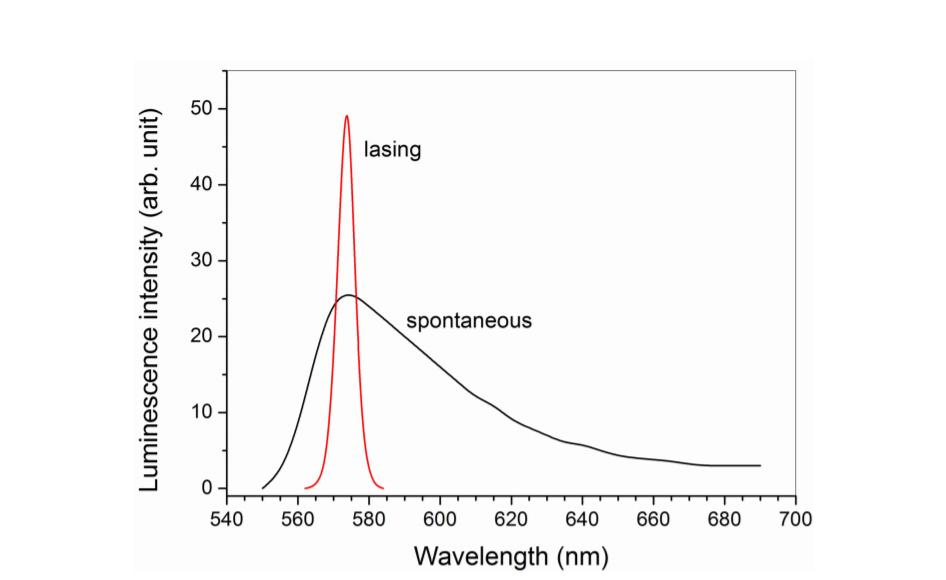

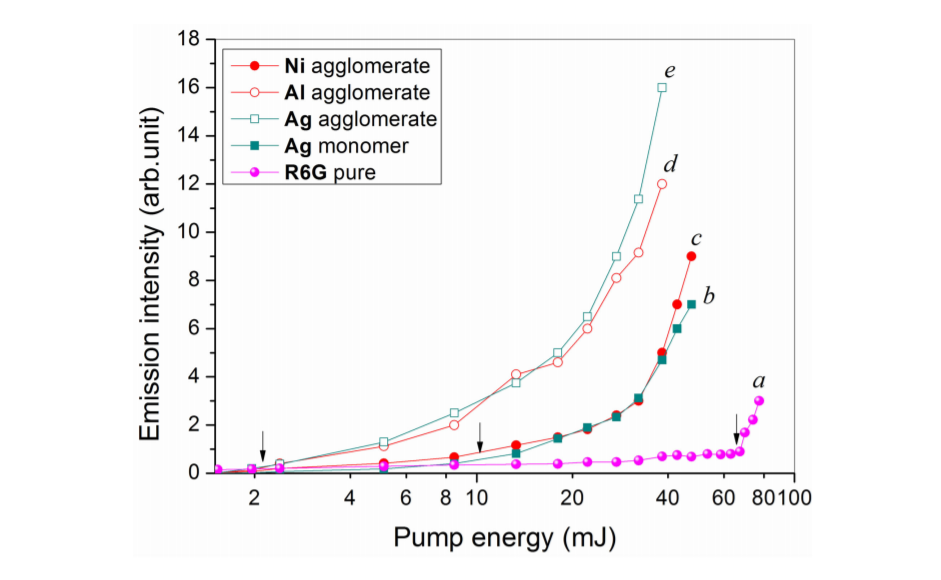

As an example, consider Figs. \(\PageIndex{4}\) and \(\PageIndex{5}\) which are from [99]. Figure \(\PageIndex{4}\) relates to a dye laser where the active material is a liquid solution of the organic dye rhodamine 6G mixed with silver nanoparticles. Curve \(a\) of Fig. \(\PageIndex{5}\) relates to a dye laser with rhodamine 6G as the active material. The other curves of Fig. \(\PageIndex{5}\) relate to dye lasers with active materials made from rhodamine 6G doped with various nanoparticles. Typically, lasing will only occur if the active material is pumped strongly enough. If less energy is supplied, spontaneous emission occurs. Above a threshold, some spontaneous emission still occurs, but stimulated emission dominates. Figure \(\PageIndex{4}\) plots the intensity of light emitted at two different pumping levels, above and below the threshold for lasing. From this figure, we can see that the bandwidth of light emitted when the device is producing only spontaneous emission is much broader than the bandwidth of light emitted when the device is lasing. The FWHM and quality factor in each case can be approximated from this figure. For the spontaneous emission curve, FWHM\(_{[nm]} \approx 45\) nm and quality factor \(\approx 13\). For the stimulated emission curve, FWHM\(_{[nm]} \approx 5\) nm and quality factor (\approx 115\). While these values are for dye lasers, other types of lasers, especially gas lasers, can have FWHM values which are orders of magnitude smaller, and values of 0.01 nm are achievable [83, p. 625]. Figure \(\PageIndex{5}\) illustrates another feature typical of lasers. Consider curve a which shows the intensity of the output versus pump energy supplied. The arrow in the figure near 65 mJ indicates the lasing threshold. Once lasing occurs, the intensity of the light emitted increases due to the optical feedback, so a discontinuity in the slope of plots of this type can be seen at the lasing threshold.

Laser Types

Engineers have developed many types of lasers utilizing a wide range of active materials. Lasers can be classified based on the type of active material as gas lasers, dye lasers, solid state lasers, or semiconductor lasers. Most lasers fit into one of these four categories, but there are exceptions such as free electron lasers where lasing occurs between energy levels of unbound electrons [31, p. 277] [86, p. 417].

lasers

In a gas laser, the active material is a gas, and lasing occurs between energy levels of a neutral or ionized atom. Gas lasers are constructed from a gas filled glass tube. Electrodes inside the tube supply power to excite electrons of the gas atoms, and external mirrors form the cavity. One of the more common gas lasers is the helium neon laser, which typically operates at 632.8 nm [31, ch. 10]. However, the laser cavity may be designed so that lasing occurs at \(3.39 \mu m\) and at other wavelengths too [31, ch. 10]. Another example of a common gas laser is the argon ion laser in which lasing occurs between energy levels of ionized argon. One advantage of gas lasers compared to other types of lasers is that they can be electrically pumped. Another advantage is that gas lasers can be designed to have high output powers. For this reason, gas lasers are used in applications requiring high power such as cutting, welding, and weaponry [86, p. 405]. Carbon dioxide lasers can produce hundreds of kilowatts of power when operating continuous wave and terawatts of power when operating pulsed [86, p. 405]. However, gas lasers are often physically large in size and not as portable as semiconductor lasers. High power gas lasers typically also require water cooling or another form of cooling.

Lasers

In dye lasers, the active material is a solute in a liquid, and dye lasers are often optically pumped by other lasers [86, p. 386]. Lasing may occur between molecular vibration energy levels as opposed to electron energy levels [31, p. 225] [86, p. 386]. An advantage of dye lasers is that they may be tunable over a wide range of wavelengths. However, dye lasers require regular maintenance because the dyes have a finite useful lifetime [86, p. 391]. One example of a dye used is the organic molecule rhodamine 6G, and lasers using this dye are tunable from \(570 < \lambda < 610\) nm [31, p. 228] [86, p. 387]. Figures \(\PageIndex{4}\) and \(\PageIndex{5}\) illustrate the behavior of a dye laser of this type.

Solid state lasers

The active material of a solid state laser is a solid insulating material, often a high purity crystal, doped with some element. Lasing occurs between electron energy levels of the dopant embedded in the solid. External mirrors are used to form the cavity. Solid state lasers are typically optically pumped by lamps or other lasers. A ruby laser is a solid state laser with an active material made from a crystal of sapphire, Al\(_2\)O\(_3\), doped with around 0.05% by weight of chromium Cr\(^{3+}\) ions [31, ch. 10 ]. Ruby lasers are three level lasers [10, p. 476]. Another common solid state laser is a neodymium yttrium aluminum garnet laser, often denoted Nd:YAG, which is a four level laser. The active material of this laser is yttrium aluminum garnet Y\(_3\)Al\(_5\)O\(_{12}\) doped with around 1% of neodymium Nd\(^{3+}\) ions, and this laser produces infrared light at \(\lambda = 1.0641 \mu m\) [10, p. 478] [31, p. 208] [86, p. 539]. Another common laser is the titanium doped sapphire laser, denoted Ti:Sapph. The active material of this laser is sapphire Al\(_2\)O\(_3\) doped with about one percent of titanium ions Ti\(^{3+}\). This laser is tunable in the range \(700 < \lambda < 1020\) nm [86, p. 392]. Tuning is achieved through an adjustable prism inside the laser cavity and through coatings on the mirrors of the cavity. Due to the tunability, these lasers are used for spectroscopy and materials research.

Semiconductor lasers

The active material of a semiconductor laser is a solid semiconductor pn junctions. An intrinsic, undoped, layer may be added between the p-type layer and the n-type layer at the junction to increase the width of the depletion region and improve overall efficiency [10, p. 567]. As with diodes and LEDs, the entire device typically fits inside a cubic millimeter. The wavelength emitted depends on the energy gap of the semiconductor. The first semiconductor lasers were made from gallium arsenide and produced infrared light [93]. Since then, semiconductor lasers emitting at all visible frequencies have been produced. It took over thirty years from the time the first semiconductors were produced to the time reliable blue lasers were produced [90] [100]. The first blue semiconductor lasers were produced using ZnMgSSe, and more commonly now GaN is used. Developing this technology required the ability to deposit very pure layers of the semiconductors without developing mechanical strain in the layers.

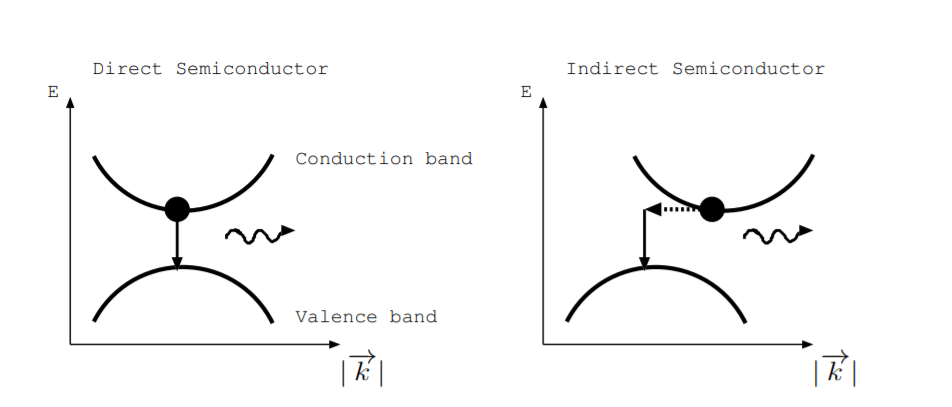

Almost all semiconductor lasers are made from direct semiconductors. It is for this reason that the first semiconductor lasers were made from GaAs even though silicon processing technology was more developed at the time [93]. Direct semiconductors were defined in Section 6.3 and illustrated in Fig. 6.3.1. In a direct semiconductor, the top of the valence band and the bottom of the conduction band line up in a plot of energy levels versus wave vector \(|\overrightarrow{k}|\).

Figure \(\PageIndex{6}\) is a sketch of energy levels versus wave vector for a direct semiconductor and an indirect semiconductor. In both cases, an electron is excited to the conduction band. In both cases, the electron can decay by spontaneous emission from the conduction band to the valence band. In both cases, both energy and momentum must be conserved. In the direct semiconductor case, the electron can decay by emitting a photon. The electron does not need to change momentum in the process. While it is not shown in the figure, the electron can also decay by stimulated emission. In the indirect case, spontaneous emission can occur, but this process necessarily requires a change in momentum of the electron too. While it is possible that spontaneous emission can occur and produce a photon, often the electron decays by producing heat or vibrations instead of a photon of light [86, p. 444]. For this reason, stimulated emission is significantly less likely to occur in indirect than direct semiconductors.

As discussed above, semiconductor lasers do not have external mirrors. Semiconductor lasers can be broadly classified into two categories, edge emitters and vertical cavity surface emitting lasers (VCSELs) [101] depending on whether the optical emission is from the edge or the surface of the device. In edge emitting lasers, the cavity is often formed by the edges of the semiconductor. In other edge emitting lasers called distributed feedback semiconductor lasers, a grating, which acts as an optical filter, is etched into the semiconductor. In vertical cavity surface emitting lasers, multiple epitaxial layers of different materials form mirrors above and below the active material.

A main advantage of semiconductor lasers over other types of lasers is their small size. They can be integrated into both consumer devices like laser pointers and DVD players as well as industrial equipment and communication networks. Another large advantage is that they are electrically pumped. They also often do not need external cooling due to their relatively high overall efficiency. Another advantage is that the output wavelength can be designed by selecting the composition. For example, semiconductor lasers of composition In\(_{1−x}\)Ga\(_x\)As\(_{1−y}\)P\(_y\) produce infrared light in the range \(1.1 \mu m < \lambda < 1.6 \mu m\). This frequency range is particularly useful for optical communication networks. Fiber optic cables are made from SiO\(_2\) glass, a material with very low but nonzero absorption. Absorption is a function of wavelength, and the absorption minimum of silica glass is near \(1.55 \mu m\) [10, p. 882]. These fibers also have low, but nonzero dispersion. Dispersion refers to the spread of pulses as they propagate through the fiber. The dispersion minimum in silica glass is around \(1.3 \mu m\). [10, p. 879]. Semiconductor lasers producing light in this range can be used to transmit signals down optical fibers, and these signals will have very low absorption and dispersion. A limitation is power output. While a semiconductor laser can produce over a watt of power, gas lasers can produce orders of magnitude more power.

Optical Amplifiers

Optical amplifiers are quite similar to lasers, and they can be made from all types of active materials used to make lasers including gases, solid state materials, semiconductors, and dyes [10, p. 477]. An optical amplifier consists of a pump and active material, but it does not have a cavity. The pump excites electrons of the active material to an upper energy level. Photons of an incoming optical signal cause additional photons to be generated by stimulated emission. Amplification occurs because these incoming photons generate additional photons, but lasing does not occur without the optical feedback provided by the cavity.

Erbium doped fiber amplifiers are one of the most useful types of optical amplifiers because of their use in optical communication networks [10, p. 882]. These devices can amplify optical signals without the need to convert them to or from electrical signals. They are solid state devices where stimulated emission occurs between energy levels of erbium, a dopant, in silica glass fibers. Energy from a semiconductor laser acts as the pump which excites electrons of the erbium atoms. Erbium doped fiber amplifiers are very useful because they can amplify optical signals near the fiber absorption minimum at \(1.55 \mu m\).