7.4: A Head Loss Model for Sliding Bed Slurry Transport

- Page ID

- 29230

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\dsum}{\displaystyle\sum\limits} \)

\( \newcommand{\dint}{\displaystyle\int\limits} \)

\( \newcommand{\dlim}{\displaystyle\lim\limits} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\(\newcommand{\longvect}{\overrightarrow}\)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)

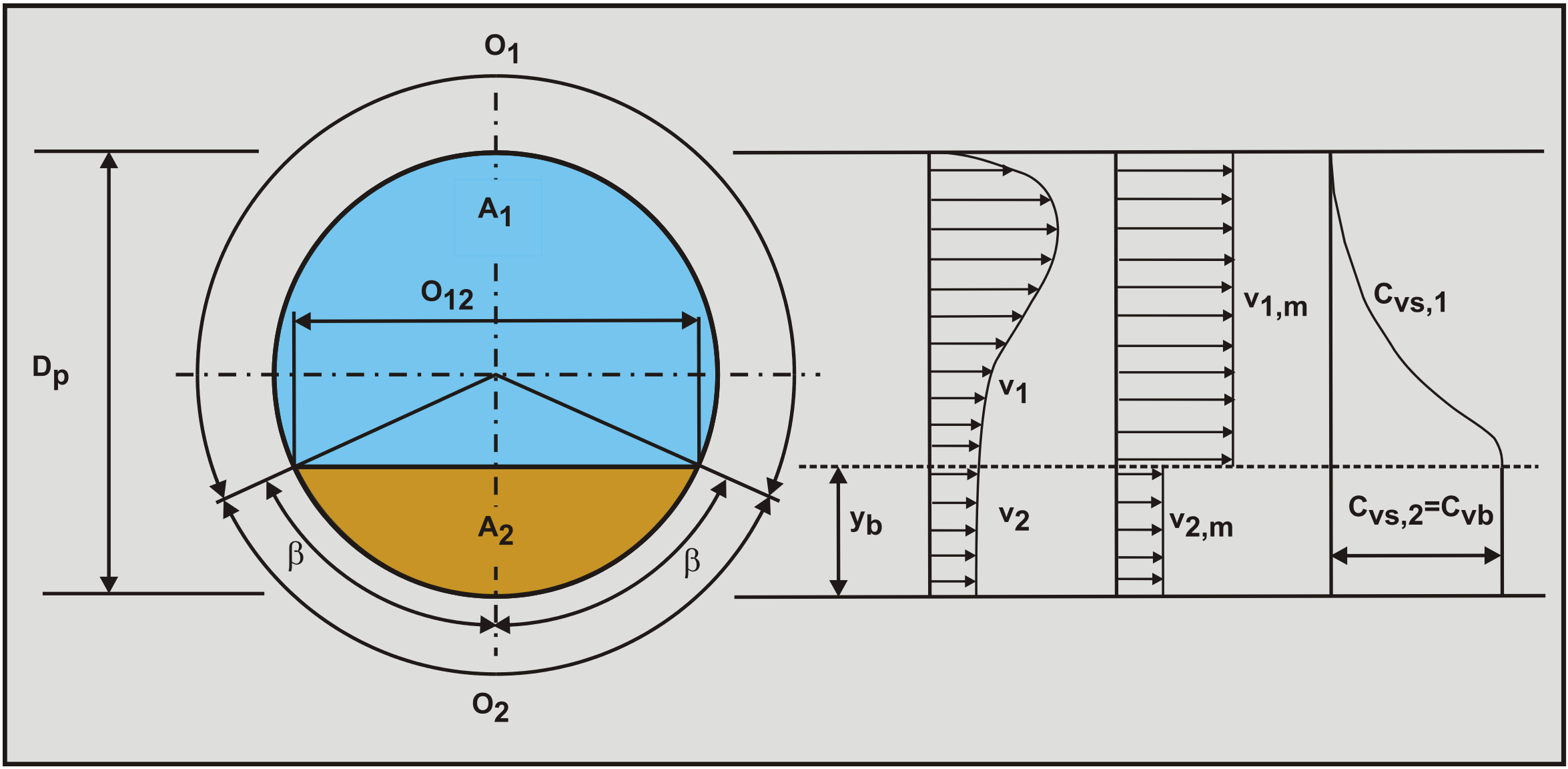

7.4.1 The Friction Force on the Pipe Wall

The friction force Fsf between the bed and the pipe wall equals the normal force Fn on the pipe wall times the friction coefficient μsf, giving:

\[\ \mathrm{F}_{\mathrm{s f}}=\mu_{\mathrm{s f}} \cdot \mathrm{F}_{\mathrm{n}}\]

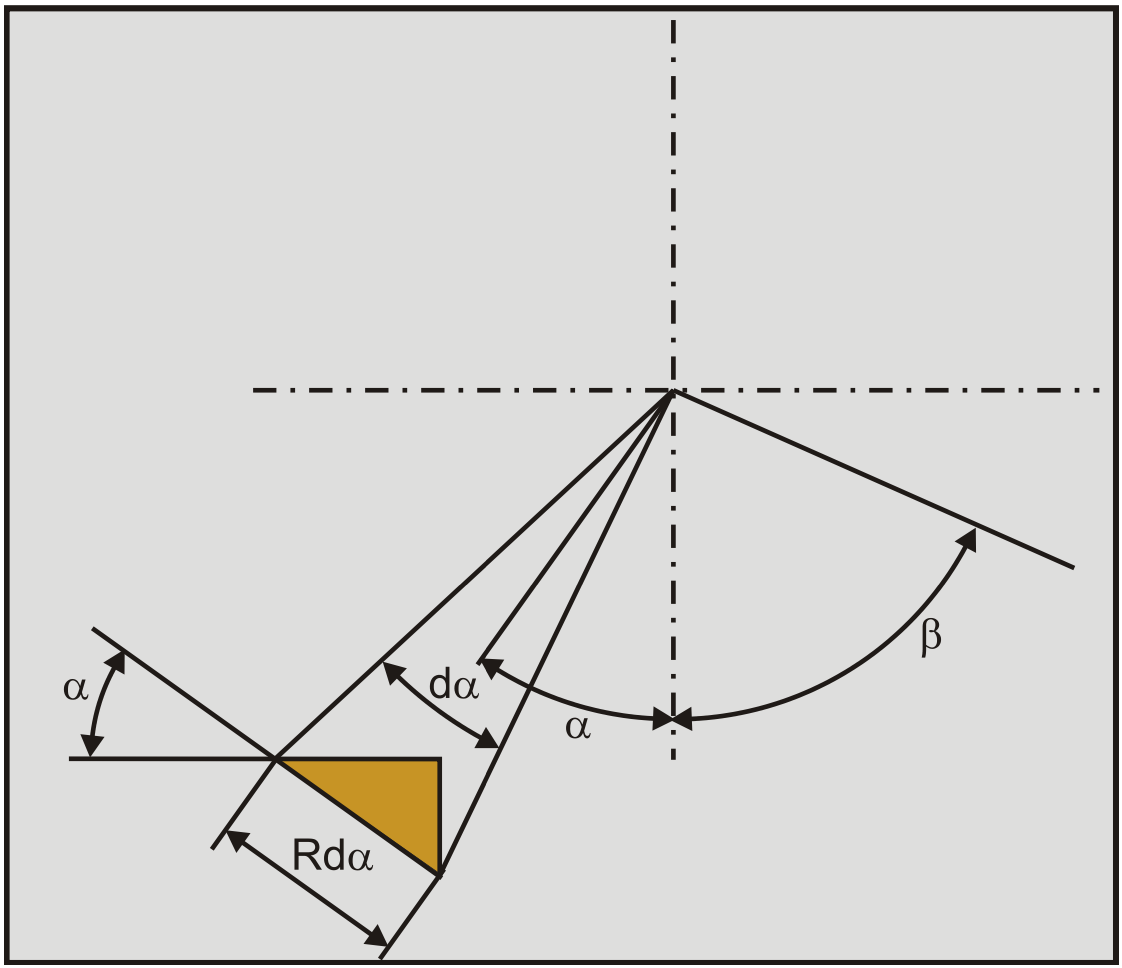

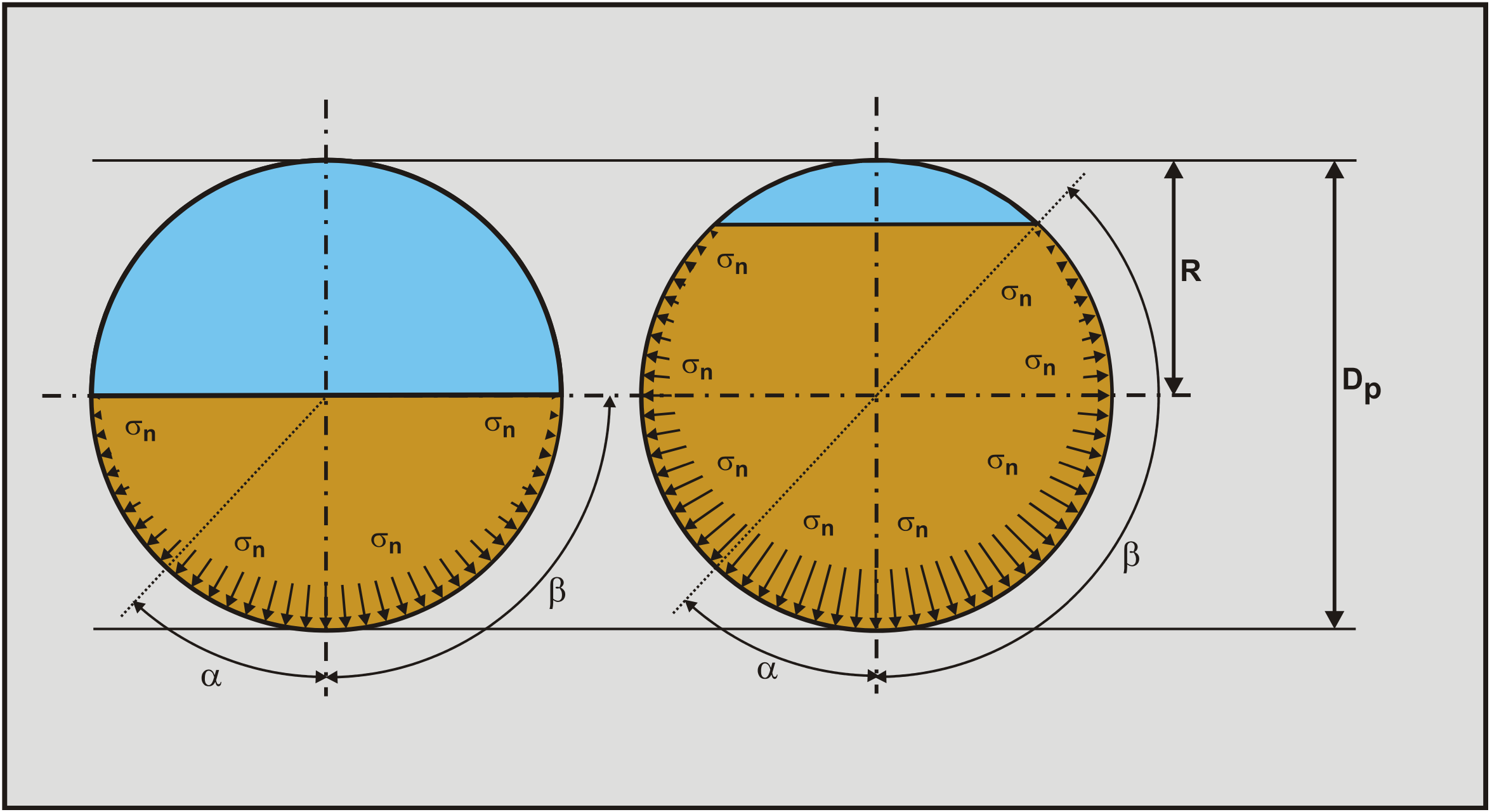

The normal force Fn on the pipe wall is the normal stress σn on the pipe wall, integrated over the contact angle β of the bed with the pipe wall.

\[\ \mathrm{F}_{\mathrm{n}}=\Delta \mathrm{L} \cdot \int_{-\beta}^{\beta} \sigma_{\mathrm{n}} \cdot \mathrm{R} \cdot \mathrm{d} \alpha=\Delta \mathrm{L} \cdot \frac{\mathrm{D}_{\mathrm{p}}}{2} \cdot \int_{-\boldsymbol{\beta}}^{\beta} \sigma_{\mathrm{n}} \cdot \mathrm{d} \alpha=\Delta \mathrm{L} \cdot \mathrm{D}_{\mathrm{p}} \cdot \int_{\mathrm{0}}^{\beta} \sigma_{\mathrm{n}} \cdot \mathrm{d} \alpha\]

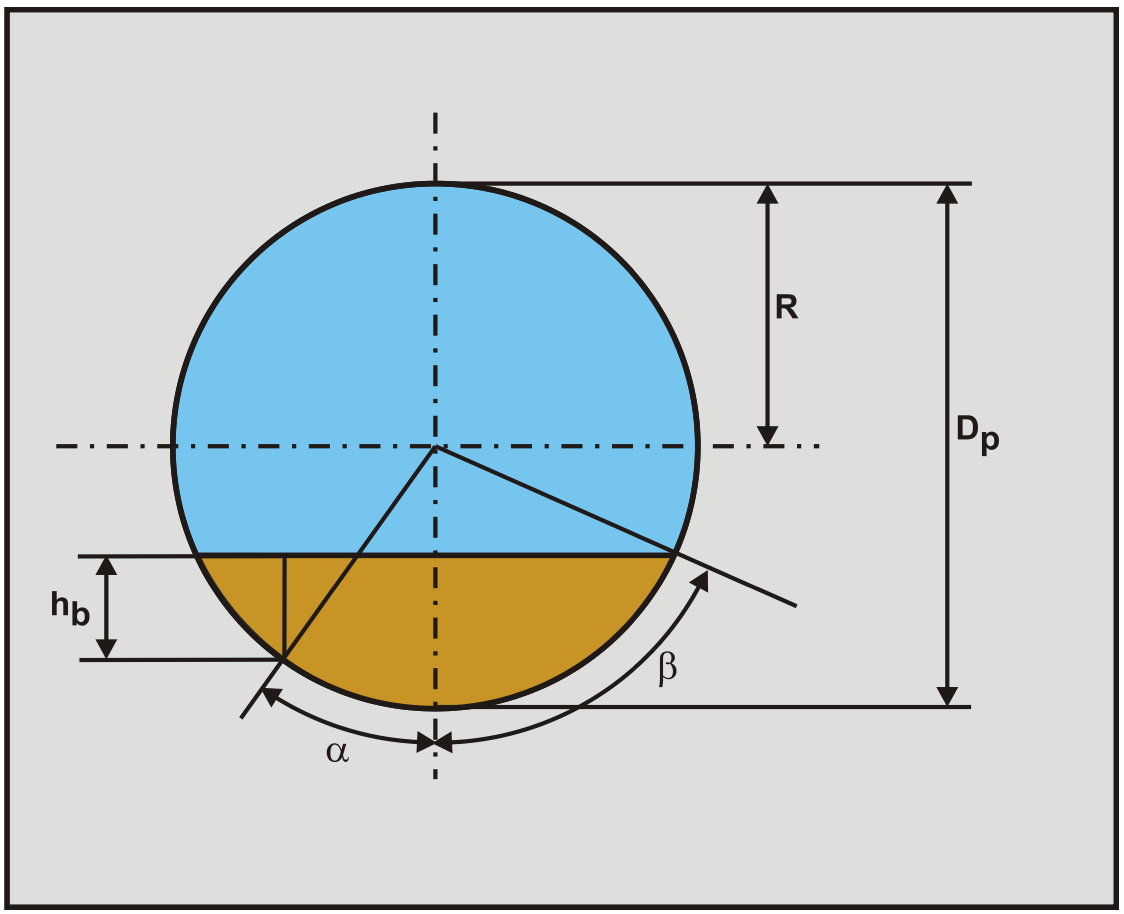

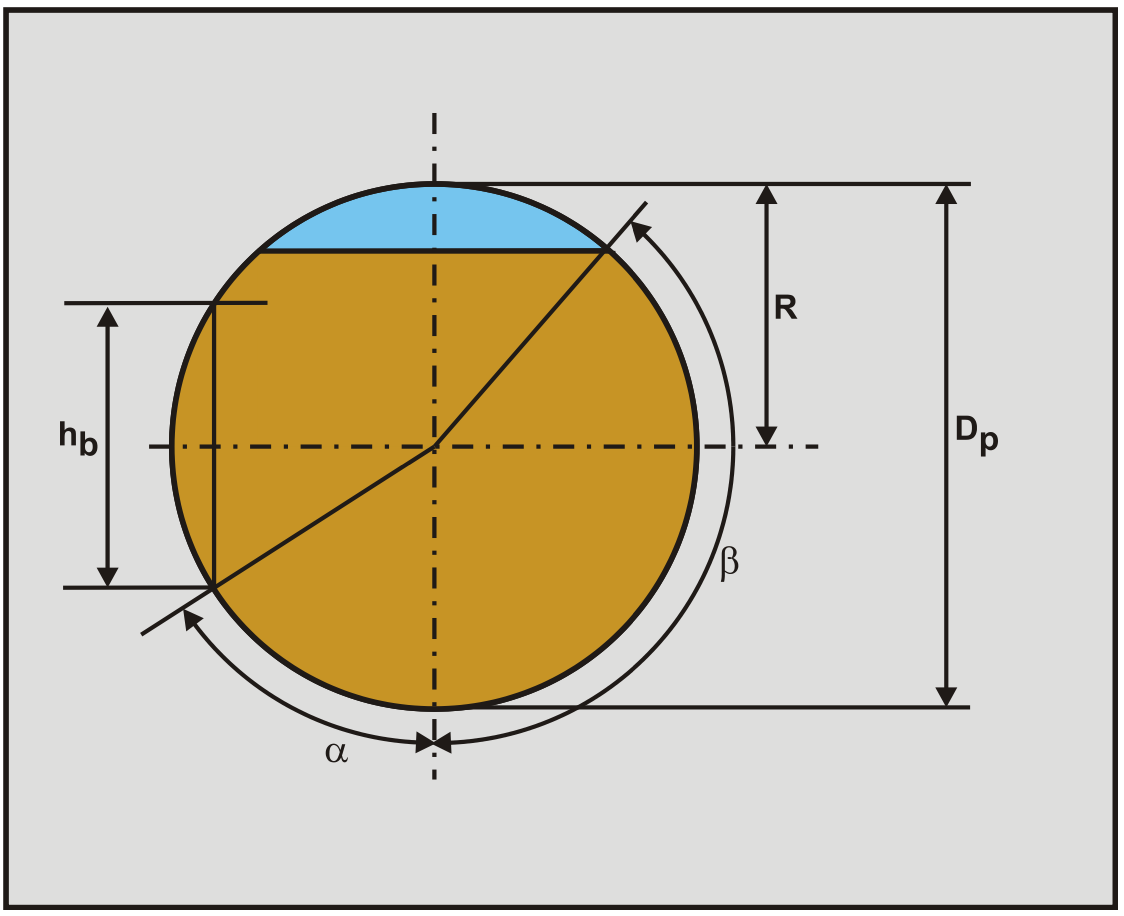

The vertical stress σv at an angle α with the vertical can be derived from the height of the bed hb at that location for β≤π/2 according to Figure 7.4-2:

\[\ \mathrm{h}_{\mathrm{b}}=\mathrm{R} \cdot(\cos (\alpha)-\cos (\beta))=\frac{\mathrm{D}_{\mathrm{p}}}{2} \cdot(\cos (\alpha)-\cos (\beta))\]

The vertical stress σv is the submerged weight per unit of area at the specific location at the pipe wall.

\[\ \sigma_{\mathrm{v}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \frac{\mathrm{D}_{\mathrm{p}}}{2} \cdot(\cos (\alpha)-\cos (\beta))\]

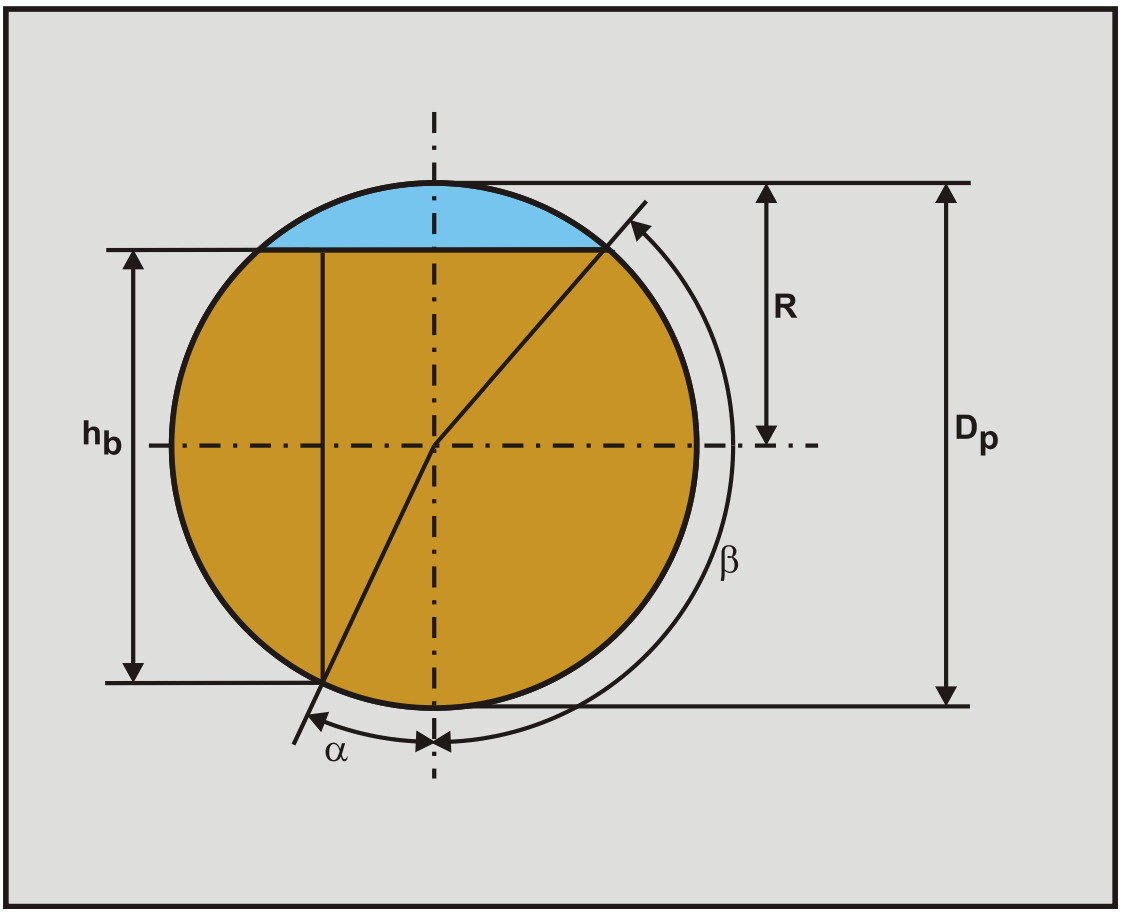

It should be mentioned that the height hb is different for an angle β≤π/2. For β≤π/2 there are two cases.

For 0≤α<π-β the vertical stress is based on the distance from the pipe wall at angle α to the free surface of the bed according to Figure 7.4-7, giving for the height of the bed column:

\[\ \mathrm{h_{b}}=\mathrm{R} \cdot(\cos (\alpha)-\cos (\beta))=\frac{\mathrm{D_{p}}}{2} \cdot(\cos (\alpha)-\cos (\beta))\]

And for the vertical normal stress:

\[\ \sigma_{\mathrm{v}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vb}} \cdot(\cos (\alpha)-\cos (\beta)) \cdot \frac{\mathrm{D}_{\mathrm{p}}}{2}\]

For π-β<α<π/2 the normal stress is based on the two times distance from the pipe wall at angle α to the center line of the pipe according to Figure 7.4-6, giving for the height of the bed column:

\[\ \mathrm{h}_{\mathrm{b}}=\mathrm{2} \cdot \mathrm{R} \cdot \cos (\alpha)=\mathrm{D}_{\mathrm{p}} \cdot \cos (\alpha)\]

And for the vertical normal stress:

\[\ \sigma_{\mathrm{v}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R_{s d}} \cdot \mathrm{C_{v b}} \cdot 2 \cdot \cos (\alpha) \cdot \frac{\mathrm{D_{p}}}{2}\]

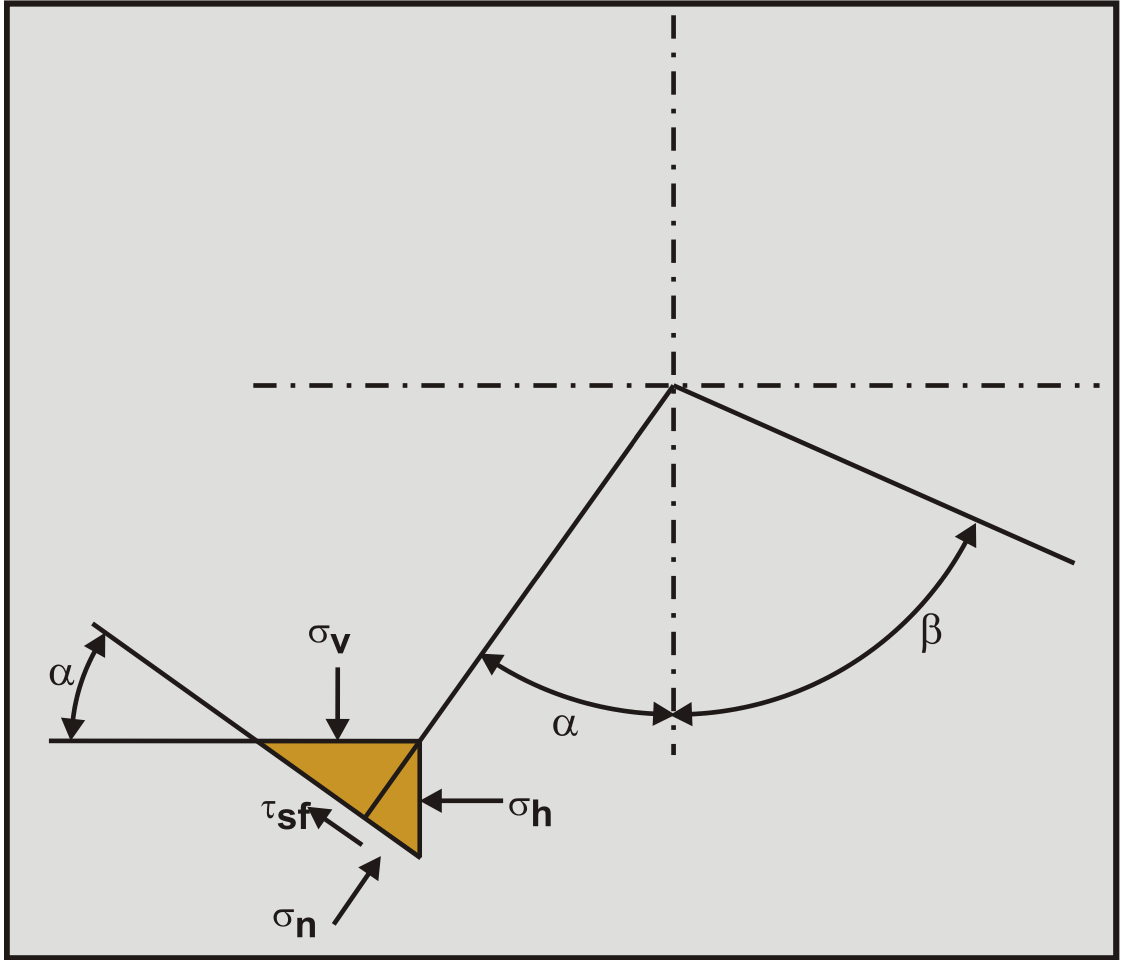

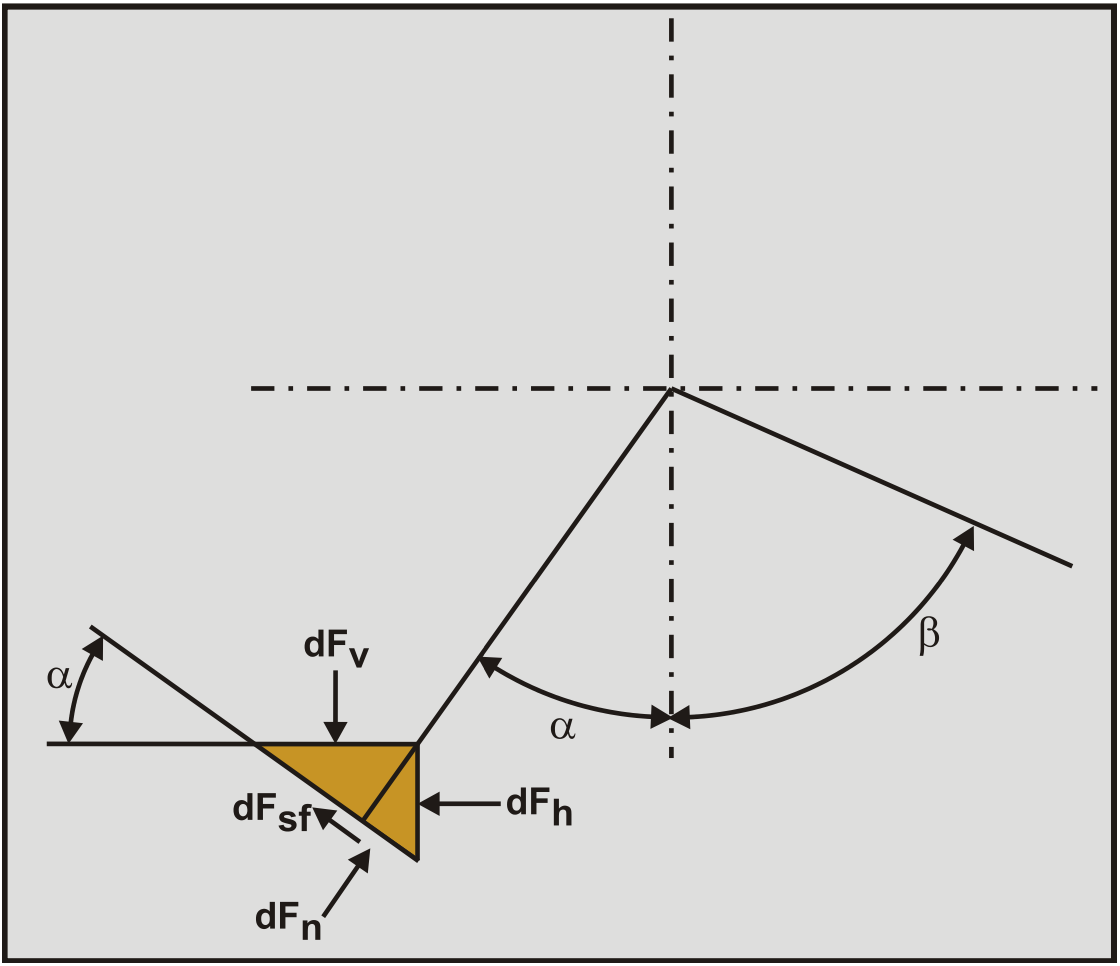

On the bed element at the pipe wall (Figure 7.4-5) there has to be an equilibrium of forces in the horizontal and in the vertical direction, thus for the vertical direction.

\[\ \mathrm{d F}_{\mathrm{n}} \cdot \cos (\alpha)+\mathrm{d F}_{\mathrm{s f}} \cdot \sin (\alpha)=\mathrm{d} \mathrm{F}_{\mathrm{v}}\]

For the horizontal direction this gives:

\[\ \mathrm{d F}_{\mathrm{n}} \cdot \sin (\alpha)-\mathrm{d} \mathrm{F}_{\mathrm{s f}} \cdot \cos (\alpha)=\mathrm{d} \mathrm{F}_{\mathrm{h}}\]

In terms of stresses this gives for the vertical equilibrium:

\[\ \mathrm{\sigma_{n} \cdot \cos (\alpha) \cdot R \cdot d \alpha+\tau_{s f} \cdot \sin (\alpha) \cdot R \cdot d \alpha=\sigma_{v} \cdot R \cdot d \alpha \cdot \cos (\alpha)}\]

For the horizontal equilibrium this gives:

\[\ \mathrm{\sigma_{n} \cdot \sin (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha-\tau_{s f} \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha=\sigma_{h} \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \sin (\alpha)}\]

With the relation between the normal stress and the shear stress:

\[\ \tau_{\mathrm{s f}}=\mu_{\mathrm{s f}, \mathrm{e}} \cdot \sigma_{\mathrm{n}}\]

This gives for the vertical equilibrium:

\[\ \mathrm{\sigma_{n} \cdot\left(\cos (\alpha)+\mu_{s f, e} \cdot \sin (\alpha)\right) \cdot R \cdot d \alpha}=\mathrm{\sigma_{v} \cdot R \cdot d \alpha \cdot \cos (\alpha)}\]

For the horizontal equilibrium this gives:

\[\ \mathrm{\sigma_{n} \cdot\left(\sin (\alpha)-\mu_{\mathrm{sf}, \mathrm{e}} \cdot \cos (\alpha)\right) \cdot \mathrm{R} \cdot \mathrm{d} \alpha}=\sigma_{\mathrm{h}} \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \sin (\alpha)\]

Since friction is always in the opposite direction of the interface velocity, 3 cases can be distinguished:

- The bed is stationary and the liquid above the bed is also stationary. Since there is no velocity in any direction, the friction can be mobilized between 0 and a maximum value in any direction, counteracting forces that may occur. Since in this case the only force is the gravitational force, there may be friction between the bed and the pipe wall counteracting gravity with a maximum of μsf,e= μsf.

- The bed is stationary, but the liquid above the bed has a certain velocity resulting in a shear stress and thus shear force on the bed. There will be a friction force between the bed and the pipe wall counteracting the shear force on the bed, but this does not mean the friction is fully mobilized. There may still be some friction capacity left counteracting gravity in the cross section of the pipe.

- The bed is sliding. The friction force on the bed is opposite to the velocity of the bed. There is no friction mobilized in the cross section of the pipe, so μsf,e=0.

When the line speed increases from 0 m/sec to a line speed above the Limit of Stationary Deposit Velocity, the friction undergoes a transition from mobilization in the cross section of the pipe counteracting gravity, to mobilization in the longitudinal direction of the pipe counteracting shear and pressure. Since the effective mobilized friction is only known in the case of a sliding bed, first a generic solution will be derived for the normal force between the bed and the pipe wall, taking into consideration that the integrated vertical components of the normal force and the wall friction force should always be equal to the weight of the bed.

7.4.2 The Active/Passive Soil Failure Approach

Given a vertical stress σv at the pipe wall according to equation (7.4-4) for the case where β≤π/2 and equations (7.4-6) and (7.4-8) for the case where β>π/2 and considering that the vertical stress σv is only present in the bottom half of the pipe, it can be assumed that the horizontal stress σh is a factor K times the vertical stress σv. According to soil mechanics, this factor K should be in between the factor for active failure Ka and the factor for passive failure Kp. These two factors depend on the angle of internal friction of the sand bed φ, which for a loose packed bed will have a value near 30o. The Ka value is 1/3 and the Kp value 3 for an internal friction angle of 30o. The K value cannot be smaller than Ka or bigger than Kp.

The coefficients for active Ka and passive Kp failure are:

\[\ \mathrm{K_{a}=\frac{1-\sin (\varphi)}{1+\sin (\varphi)} \quad\text{ and }\quad K_{p}=\frac{1+\sin (\varphi)}{1-\sin (\varphi)}}\]

This gives for the horizontal stress σh near the pipe wall:

\[\ \sigma_{\mathrm{h}}=\mathrm{K} \cdot \sigma_{\mathrm{v}}\]

The forces on an element R·dα on the pipe wall per unit of pipe length are now:

\[\ \mathrm{d F}_{\mathrm{v}}=\sigma_{\mathrm{v}} \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \mathrm{\alpha} \cdot \Delta \mathrm{L}\]

\[\ \mathrm{d F}_{\mathrm{h}}=\sigma_{\mathrm{h}} \cdot \sin (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \mathrm{\alpha} \cdot \Delta \mathrm{L}\]

The components of these forces normal to the pipe wall are:

\[\ \mathrm{d F}_{\mathrm{v}, \mathrm{n}}=\sigma_{\mathrm{v}} \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \cos (\alpha) \cdot \Delta \mathrm{L}\]

\[\ \mathrm{d F}_{\mathrm{h}, \mathrm{n}}=\sigma_{\mathrm{h}} \cdot \sin (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \sin (\alpha) \cdot \Delta \mathrm{L}\]

This gives for the normal force on an element R·dα on the pipe wall:

\[\ \mathrm{d F}_{\mathrm{n}}=\mathrm{d F}_{\mathrm{v}, \mathrm{n}}+\mathrm{d} \mathrm{F}_{\mathrm{h}, \mathrm{n}}=\sigma_{\mathrm{v}} \cdot \cos ^{2}(\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}+\sigma_{\mathrm{h}} \cdot \sin ^{2}(\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

Substituting equation (7.4-17) gives:

\[\ \mathrm{d F}_{\mathrm{n}}=\mathrm{d F}_{\mathrm{v}, \mathrm{n}}+\mathrm{d} \mathrm{F}_{\mathrm{h}, \mathrm{n}}=\sigma_{\mathrm{v}} \cdot\left(\cos ^{2}(\alpha)+\mathrm{K} \cdot \sin ^{2}(\alpha)\right) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

The normal stress on the pipe wall is now:

\[\ \sigma_{\mathrm{n}}=\frac{\mathrm{dF}_{\mathrm{n}}}{\mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}}=\frac{\mathrm{dF}_{\mathrm{v}, \mathrm{n}}+\mathrm{d} \mathrm{F}_{\mathrm{h}, \mathrm{n}}}{\mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}}=\sigma_{\mathrm{v}} \cdot\left(\cos ^{2}(\alpha)+\mathrm{K} \cdot \sin ^{2}(\alpha)\right)\]

To determine the total normal force Fn on the pipe wall, this normal stress has to be integrated. Two cases have to be considered. The first case considers a bed which occupies less than or equal to 50% of the pipe, so β≤π/2. The second case considers a bed which occupies more than 50% of the pipe, so β>π/2.

Case 1: β≤π/2

For 0≤α<β the normal stress is based on the distance from the pipe wall at angle α to the free surface of the bed as is shown in Figure 7.4-2, giving:

\[\ \sigma_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{R} \cdot(\cos (\alpha)-\cos (\beta)) \cdot\left(\mathrm{K} \cdot \sin ^{2}(\alpha)+\cos ^{2}(\alpha)\right)\]

Integrating from α=0 to α=β and multiplying by 2 for the left and right side gives for the normal force:

\[\ \mathrm{F}_{\mathrm{n}}=\mathrm{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{R}^{2} \cdot \int_{\mathrm{0}}^{\beta}(\cos (\alpha)-\cos (\beta)) \cdot\left(\mathrm{K} \cdot \sin ^{2}(\alpha)+\cos ^{2}(\alpha)\right) \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

Substituting the upper and lower boundary gives:

\[\ \mathrm{F}_{\mathrm{n}}=\mathrm{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{R}^{2} \cdot\left(\frac{\mathrm{K}-\mathrm{1}}{\mathrm{3}} \cdot \sin ^{3}(\beta)+\sin (\beta)-\frac{\mathrm{K}+\mathrm{1}}{2} \cdot \beta \cdot \cos (\beta)+\frac{\mathrm{K}-\mathrm{1}}{2} \cdot \sin (\beta) \cdot \cos ^{2}(\beta)\right) \cdot \Delta \mathrm{L}\]

Case 2: β>π/2

For 0≤α<π-β the normal stress is based on the distance from the pipe wall at angle α to the free surface of the bed, giving:

\[\ \sigma_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{R} \cdot(\cos (\alpha)-\cos (\beta)) \cdot\left(\mathrm{K} \cdot \sin ^{2}(\alpha)+\cos ^{2}(\alpha)\right)\]

For π-β<α<π/2 the normal stress is based on the two times distance from the pipe wall at angle α to the center line of the pipe, giving:

\[\ \sigma_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{R} \cdot \mathrm{2} \cdot \cos (\alpha) \cdot\left(\mathrm{K} \cdot \sin ^{2}(\alpha)+\cos ^{2}(\alpha)\right)\]

Integrating from α=0 to α= π/2 gives for the normal force:

\[\ \begin{array}{left}\mathrm{F_{n}}&=\mathrm{2 \cdot \rho_{l} \cdot R_{s d} \cdot g \cdot C_{v b} \cdot R^{2} \cdot \int_{0}^{\pi-\beta}(\cos (\alpha)-\cos (\beta)) \cdot\left(K \cdot \sin ^{2}(\alpha)+\cos ^{2}(\alpha)\right) \cdot d \alpha \cdot \Delta L}\\

&\mathrm{+2 \cdot \rho_{l} \cdot R_{s d} \cdot g \cdot C_{v b} \cdot R^{2} \cdot \int_{\pi-\beta}^{\pi / 2} 2 \cdot \cos (\alpha) \cdot\left(K \cdot \sin ^{2}(\alpha)+\cos ^{2}(\alpha)\right) \cdot d \alpha \cdot \Delta L}\end{array}\]

Substituting the upper and lower boundaries gives:

\[\ \mathrm{F_n = 2 \cdot \rho_l \cdot R_{sd} \cdot g \cdot C_{vb} \cdot R^2 \cdot}\Delta \mathrm{L} \cdot\left(\begin{array}{l}\frac{\mathrm{K}-\mathrm{1}}{\mathrm{3}} \cdot \sin ^{3}(\beta)+\sin (\beta)-\frac{\mathrm{K}+\mathrm{1}}{2} \cdot(\pi-\beta) \cdot \cos (\beta)-\frac{\mathrm{K}-\mathrm{1}}{2} \cdot \sin (\beta) \cdot \cos ^{2}(\beta) \\ +\frac{2}{3} \cdot(\mathrm{K}-1)+2-\frac{2}{3} \cdot(\mathrm{K}-1) \cdot \sin ^{3}(\beta)-2 \cdot \sin (\beta)\end{array}\right)\]

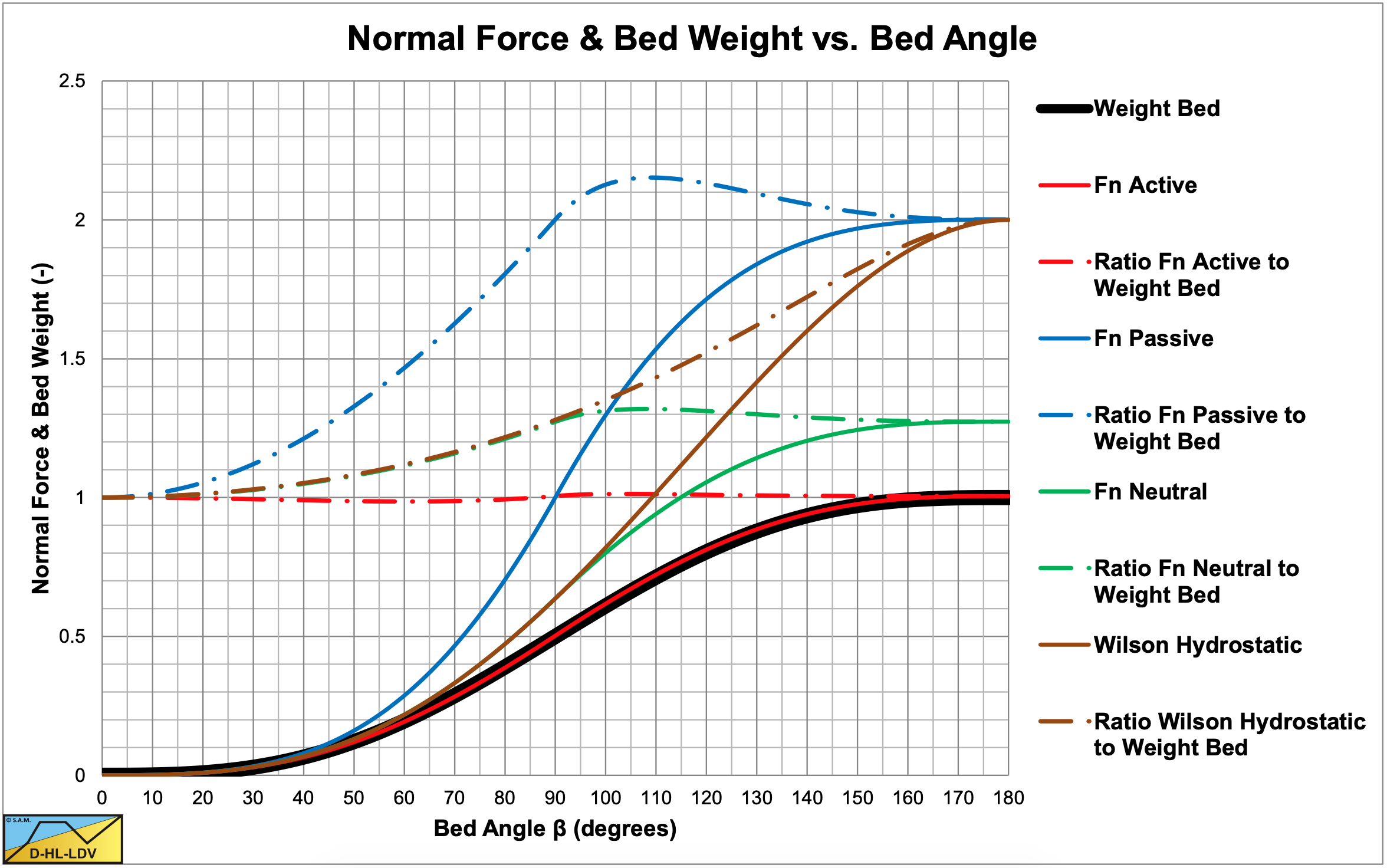

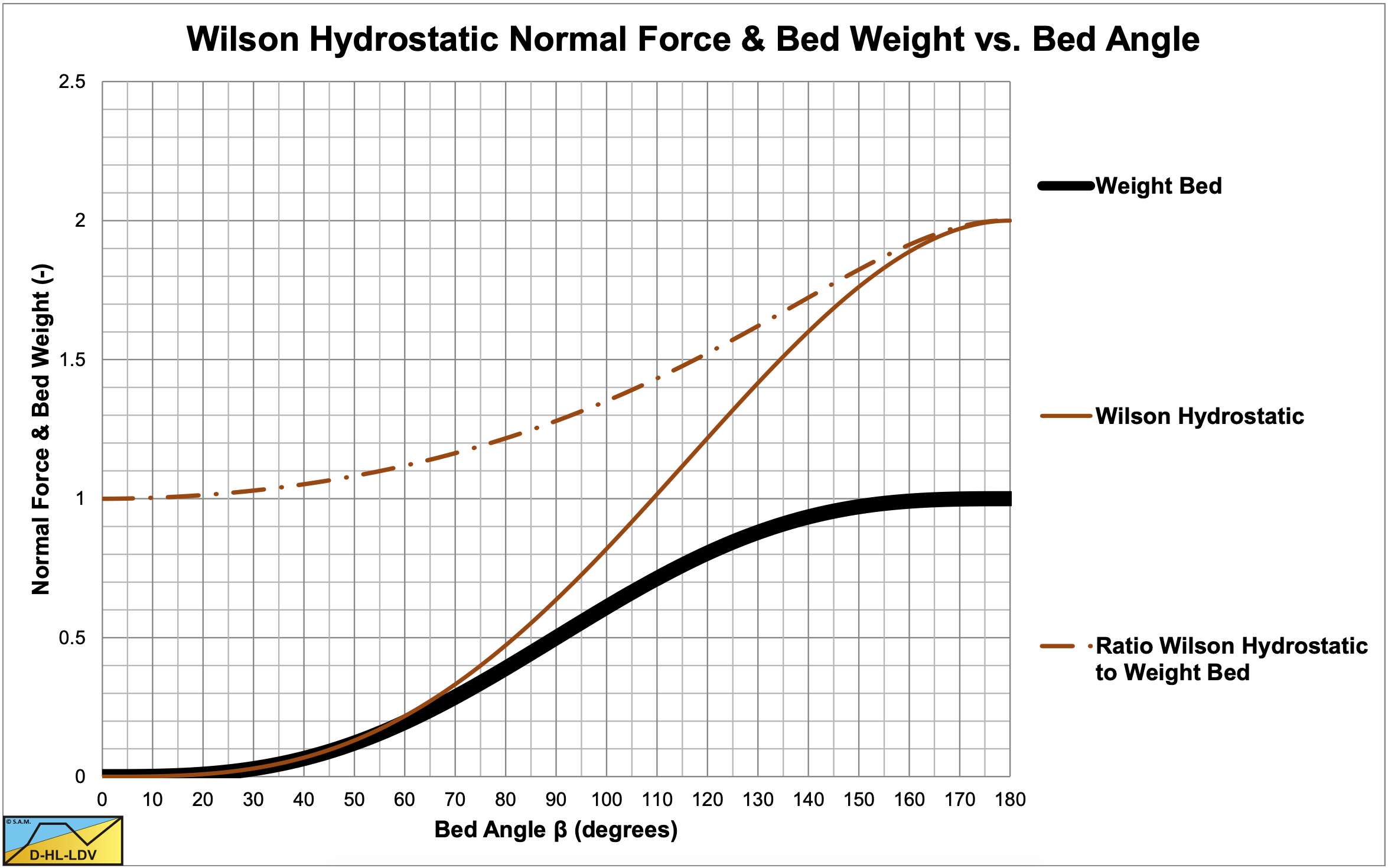

Figure 7.4-8 Shows the results of equations (7.4-27) and (7.4-31) for the cases of active failure K=Ka, passive failure K=Kp and neutral K=1 for an angle of internal friction of φ=27.5o. The figure also shows the weight of the bed and the ratio between the normal force and the weight for all cases.

The components of these forces tangent to the pipe wall are:

\[\ \mathrm{d} \mathrm{F}_{\mathrm{v}, \mathrm{t}}=\sigma_{\mathrm{v}} \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \sin (\alpha) \cdot \Delta \mathrm{L}\]

\[\ \mathrm{d F}_{\mathrm{h}, \mathrm{t}}=-\sigma_{\mathrm{h}} \cdot \sin (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \cos (\alpha) \cdot \Delta \mathrm{L}\]

This gives for the tangent force on an element R·dα on the pipe wall:

\[\ \mathrm{d F}_{\mathrm{t}}=\mathrm{d F}_{\mathrm{v}, \mathrm{t}}+\mathrm{d F}_{\mathrm{h}, \mathrm{t}}=\sigma_{\mathrm{v}} \cdot \sin (\alpha) \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \mathrm{\alpha} \cdot \Delta \mathrm{L}-\sigma_{\mathrm{h}} \cdot \sin (\alpha) \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

Substituting equation (7.4-17) gives:

\[\ \mathrm{d} \mathrm{F}_{\mathrm{t}}=\mathrm{d} \mathrm{F}_{\mathrm{v}, \mathrm{t}}+\mathrm{d} \mathrm{F}_{\mathrm{h}, \mathrm{t}}=\sigma_{\mathrm{v}} \cdot \sin (\alpha) \cdot \cos (\alpha) \cdot(\mathrm{1}-\mathrm{K}) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

The tangential or friction stress on the pipe wall is now:

\[\ \tau_{\mathrm{sf}}=\tau_{\mathrm{t}}=\frac{\mathrm{d} \mathrm{F}_{\mathrm{t}}}{\mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}}=\frac{\mathrm{d} \mathrm{F}_{\mathrm{v}, \mathrm{t}}+\mathrm{d} \mathrm{F}_{\mathrm{h}, \mathrm{t}}}{\mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}}=\sigma_{\mathrm{v}} \cdot \sin (\alpha) \cdot \cos (\alpha) \cdot(1-\mathrm{K})=\mu_{\mathrm{sf}, \mathrm{e}} \cdot \sigma_{\mathrm{n}}\]

With:

\[\ \sigma_{\mathrm{n}}=\frac{\mathrm{dF}_{\mathrm{n}}}{\mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}}=\frac{\mathrm{d} \mathrm{F}_{\mathrm{v}, \mathrm{n}}+\mathrm{d} \mathrm{F}_{\mathrm{h}, \mathrm{n}}}{\mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}}=\sigma_{\mathrm{v}} \cdot\left(\cos ^{2}(\alpha)+\mathrm{K} \cdot \sin ^{2}(\alpha)\right)\]

Giving:

\[\ \sin (\alpha) \cdot \cos (\alpha) \cdot(1-\mathrm{K})=\mu_{\mathrm{sf}, \mathrm{e}} \cdot\left(\cos ^{2}(\alpha)+\mathrm{K} \cdot \sin ^{2}(\alpha)\right)\]

The K factor is related to the wall friction coefficient according to:

\[\ \mathrm{K}=\frac{\sin (\alpha) \cdot \cos (\alpha)-\mu_{\mathrm{sf}, \mathrm{e}} \cdot \cos ^{2}(\alpha)}{\sin (\alpha) \cdot \cos (\alpha)+\mu_{\mathrm{sf}, \mathrm{e}} \cdot \sin ^{2}(\alpha)}\]

In the case of a sliding bed, there is no friction in the cross section of the pipe (Figure 7.4-4), so the only solution is K=1, which is the neutral curve for the normal force Fn as a function of the angle β in Figure 7.4-8. In the case of a stationary bed, the relation between the factor K and the effective sliding friction coefficient μsf,e depends on the angle α, no general solution exists. K=1 will simplify the equations and also appears to be to correct value for K to ensure that the vertical component of the normal stress will carry the submerged weight of the bed. The resulting normal force Fn is bigger than the weight of the bed, starting with a factor 1 for a β=0, increasing to a factor of 1.27 at β=π/2, increasing to a maximum of 1.32 at β=0.6·π and after that decreasing slowly to 1.27 at β=π. So above β=π/2 the factor is almost constant with an average value of 1.293.

7.4.3 The Hydrostatic Normal Stress Distribution Approach

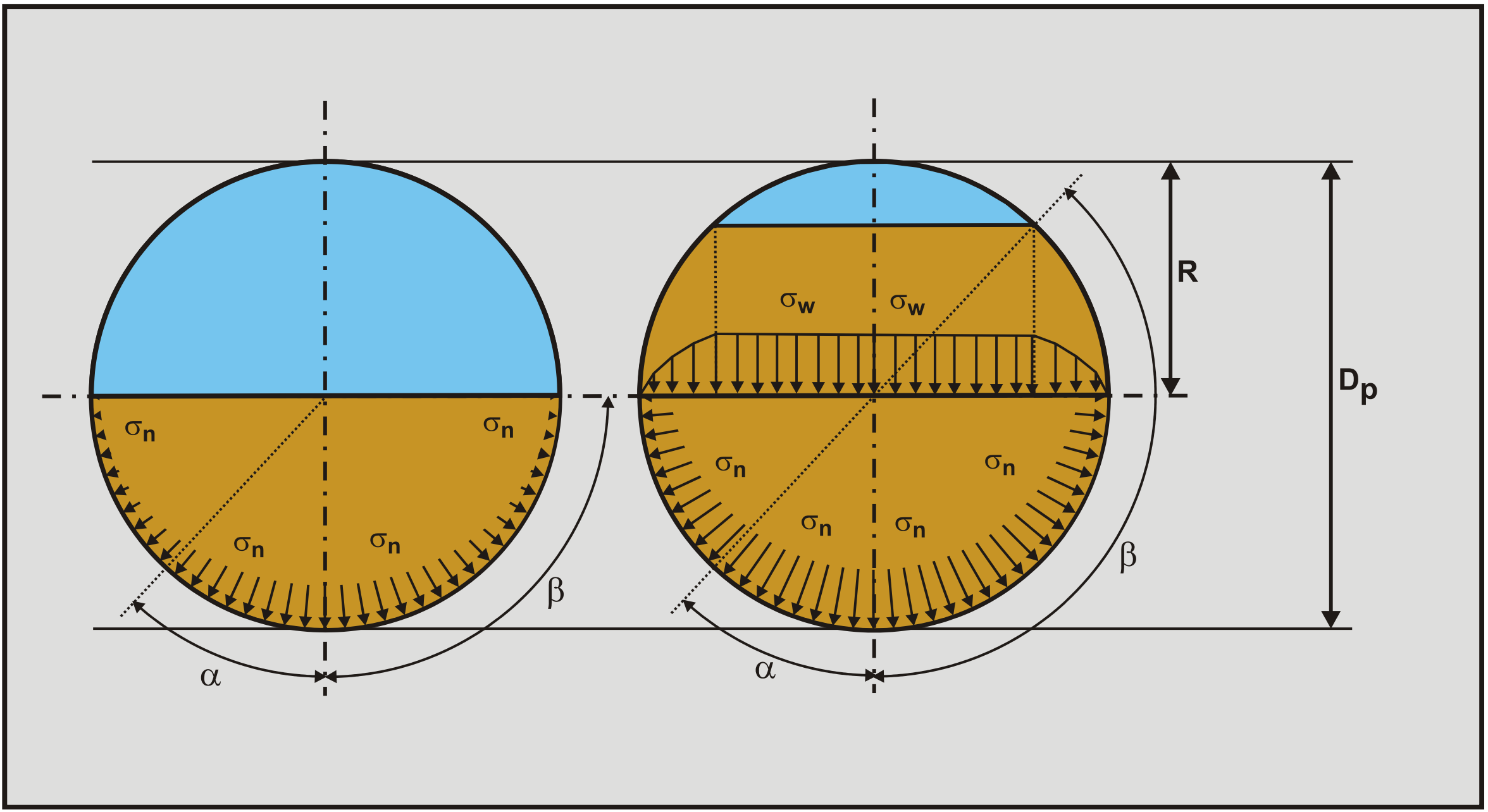

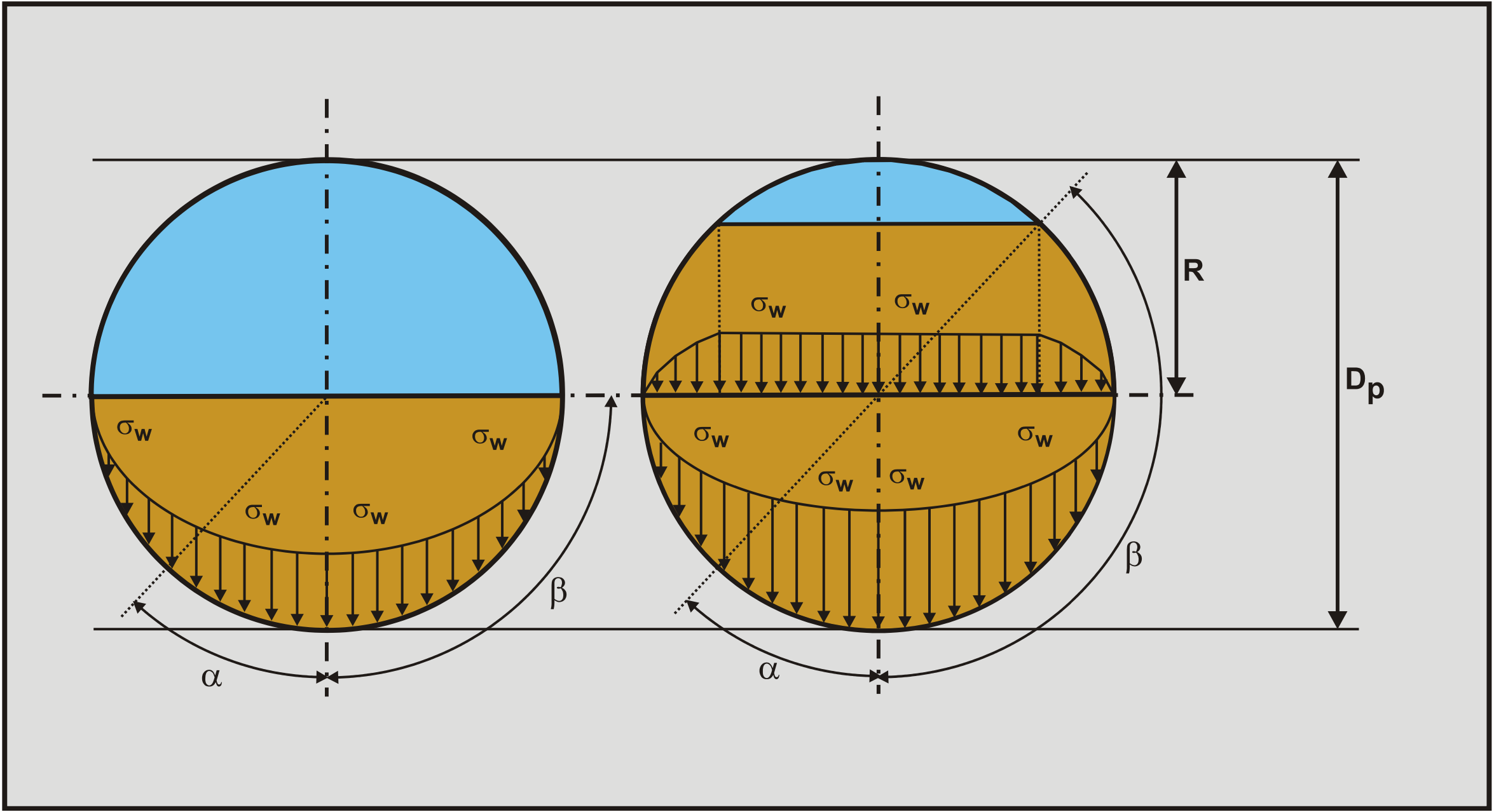

Wilson et al. (1992) assume a hydrostatic normal stress distribution on the pipe wall as if the bed was a liquid as is shown in Figure 7.4-9. The left picture shows the normal stress distribution up to a bed angle β of π/2, the right picture for β > π/2. The normal stress as a function of the angle α, given a bed angle β can be expressed by:

\[\ \sigma_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \frac{\mathrm{D}_{\mathrm{p}}}{2} \cdot(\cos (\alpha)-\cos (\beta))\]

This is different from the assumption that the friction force Fsf equals the submerged weight FW times the sliding friction coefficient μsf.

The total normal force FN follows from integration of the normal stress:

\[\ \begin{array}{left} \mathrm{F}_{\mathrm{n}}&=\Delta \mathrm{L} \cdot \int_{-\beta}^{\beta} \sigma_{\mathrm{n}} \cdot \mathrm{R} \cdot \mathrm{d} \alpha=2 \cdot \Delta \mathrm{L} \cdot \int_{\mathrm{0}}^{\beta} \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \frac{\mathrm{D}_{\mathrm{p}}^{2}}{4} \cdot(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{d} \alpha\\

&=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \frac{\mathrm{D}_{\mathrm{p}}^{2}}{2} \cdot \int_{0}^{\beta}(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{d} \alpha\end{array}\]

This gives for the normal force FN:

\[\ \mathrm{F}_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{\Delta} \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{\mathrm{D}_{\mathrm{p}}^{2}}{\mathrm{2}} \cdot(\sin (\beta)-\boldsymbol{\beta} \cdot \cos (\boldsymbol{\beta}))\]

So the sliding friction force is:

\[\ \mathrm{F}_{\mathrm{s f}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{A}_{\mathrm{p}} \cdot \frac{(\sin (\beta)-\beta \cdot \cos (\beta))}{\pi}\]

The submerged weight of the bed Fw is given by:

\[\ \mathrm{F}_{\mathrm{w}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{A}_{\mathrm{p}} \cdot \frac{(\beta-\sin (\beta) \cdot \cos (\beta))}{\pi}\]

So the ratio between the normal force and the submerged weight is:

\[\ \mathrm{\frac{F_{n}}{F_{w}}=\frac{2 \cdot(\sin (\beta)-\beta \cdot \cos (\beta))}{(\beta-\sin (\beta) \cdot \cos (\beta))}}\]

For small values of β, up to 60 degrees, this ratio is just above 1. But at larger angles (larger concentrations), this ratio is bigger than 1, with a maximum of 2 when the whole pipe is occupied with a bed and β=π.

The pressure losses due to the sliding friction of the bed based on the hydrostatic normal stress distribution are now:

\[\ \Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s f}}}{\mathrm{A}_{\mathrm{p}}}=\frac{\mu_{\mathrm{s f}} \cdot \mathrm{F}_{\mathrm{n}}}{\frac{\pi}{\mathrm{4}} \cdot \mathrm{D}_{\mathrm{p}}^{2}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(\sin (\beta)-\beta \cdot \cos (\beta))}{\pi}\]

This gives for the hydraulic gradient:

\[\ \mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s f}}}{\mathrm{A}_{\mathrm{p}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\frac{\mu_{\mathrm{s f}} \cdot \mathrm{F}_{\mathrm{n}}}{\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(\sin (\beta)-\beta \cdot \cos (\beta))}{\pi}\]

In the case where the bed occupies the whole pipe cross section, β=π, this gives the so called plug gradient:

\[\ \mathrm{i}_{\mathrm{p} \operatorname{lug}}=\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(\sin (\pi)-\pi \cdot \cos (\pi))}{\pi}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}}\]

This gives for the relative excess hydraulic gradient Erhg:

\[\ \mathrm{E}_{\mathrm{rhg}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{s}}}=\mu_{\mathrm{sf}} \cdot \frac{2 \cdot(\sin (\beta)-\beta \cdot \cos (\beta))}{(\beta-\sin (\beta) \cdot \cos (\beta))}\]

7.4.4 The Normal Force Carrying the Weight Approach

With this approach it is assumed that there can only be a normal force between the bed and the pipe wall in the bottom half of the pipe. Bed in the top half of the pipe transfers the submerged weight to the bottom half of the pipe. If the bed occupies less than or equal to half of the pipe cross section, the solution is equal to the Wilson et al. (1992) hydrostatic approach. If the bed occupies more than half of the pipe cross section, the solution differs.

Figure 7.4-11 shows these two cases. Figure 7.4-2, Figure 7.4-3, Figure 7.4-4 and Figure 7.4-5 show the stresses on the pipe wall.

It is obvious that the vertical component of the normal stress on the pipe wall has to carry the submerged weight of the bed.

The vertical stress as a result of the submerged weight at a point under an angle α is:

\[\ \sigma_{\mathrm{v}}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{vb}} \cdot(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{R}\]

The vertical force exerted on a strip pipe wall with a length ΔL is:

\[\ \Delta \mathrm{F}_{\mathrm{v}}=\sigma_{\mathrm{v}} \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

The normal force exerted on a strip pipe wall with a length ΔL is:

\[\ \Delta \mathrm{F}_{\mathrm{n}}=\sigma_{\mathrm{n}} \cdot \mathrm{R} \cdot \mathrm{d} \mathrm{\alpha} \cdot \mathrm{\Delta} \mathrm{L}\]

The vertical component of the normal force exerted on a strip pipe wall with a length ΔL is:

\[\ \Delta \mathrm{F}_{\mathrm{n}, \mathrm{v}}=\sigma_{\mathrm{n}} \cdot \cos (\alpha) \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

The vertical component of the normal force has to be equal to the vertical force resulting from the submerged weight according to:

\[\ \mathrm{\sigma_{n} \cdot \cos (\alpha) \cdot R \cdot d \alpha \cdot \Delta L=\rho_{l} \cdot R_{s d} \cdot g \cdot C_{v b} \cdot(\cos (\alpha)-\cos (\beta)) \cdot R \cdot \cos (\alpha) \cdot R \cdot d \alpha \cdot \Delta L}\]

This can be simplified to:

\[\ \sigma_{\mathrm{n}} \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{R} \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

The total normal force follows from integration of the normal stress:

\[\ \mathrm{F}_{\mathrm{n}}=\int_{-\beta}^{\beta} \sigma_{\mathrm{n}} \cdot \mathrm{R} \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}=\mathrm{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \mathrm{R}^{2} \cdot \int_{\mathrm{0}}^{\beta}(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{d} \alpha \cdot \Delta \mathrm{L}\]

Per unit of length and for both sides of the bed this gives:

\[\ \begin{array}{left} \mathrm{F}_{\mathrm{n}}&=\mathrm{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \mathrm{R}^{2} \cdot(\sin (\beta)-\beta \cdot \cos (\beta)) \cdot \Delta \mathrm{L}\\

&=2 \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{A}_{\mathrm{p}} \cdot \frac{(\sin (\beta)-\beta \cdot \cos (\beta))}{\pi} \cdot \Delta \mathrm{L}\end{array}\]

So the sliding friction force is (equal to the Wilson et al. (1992) hydrostatic approach):

\[\ \mathrm{F}_{\mathrm{s f}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \mathrm{A}_{\mathrm{p}} \cdot \frac{(\sin (\beta)-\beta \cdot \cos (\beta))}{\pi} \cdot \Delta \mathrm{L}\]

If the bed occupies more than half the cross section of the pipe, for β>π/2 we get:

For 0≤α<π-β the normal stress is based on the distance from the pipe wall at angle α to the free surface of the bed, giving:

\[\ \sigma_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{vb}} \cdot(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{R}\]

For π-β<α<π/2 the normal stress is based on the two times distance from the pipe wall at angle α to the center line of the pipe, giving:

\[\ \sigma_{\mathrm{n}}=\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \mathrm{2} \cdot \cos (\alpha) \cdot \mathrm{R}\]

Integrating from α=0 to α= π/2 gives for the normal force:

\[\ \begin{array}{left} \mathrm{F}_{\mathrm{n}}&=2 \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \mathrm{R}^{2} \cdot \Delta \mathrm{L} \cdot \int_{0}^{\pi-\beta}(\cos (\alpha)-\cos (\beta)) \cdot \mathrm{d} \alpha\\

&+2 \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \mathrm{R}^{2} \cdot \Delta \mathrm{L} \cdot \int_{\pi-\beta}^{\pi / 2} 2 \cdot \cos (\alpha) \cdot \mathrm{d} \alpha\end{array}\]

Giving:

\[\ \begin{array}{left} \mathrm{F}_{\mathrm{n}} &=\mathrm{2} \cdot \mathrm{\rho}_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \mathrm{R}^{2} \cdot \Delta \mathrm{L} \cdot(-(\pi-\beta) \cdot \cos (\beta)+2-\sin (\beta)) \\ &=\mathrm{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \mathrm{A}_{\mathrm{p}} \cdot \Delta \mathrm{L} \cdot \frac{(-(\pi-\beta) \cdot \cos (\beta)+2-\sin (\beta))}{\pi} \end{array}\]

Giving for the sliding friction force:

\[\ \mathrm{F}_{\mathrm{sf}}=\mu_{\mathrm{sf}} \cdot 2 \cdot \rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \mathrm{A}_{\mathrm{p}} \cdot \frac{(-(\pi-\beta) \cdot \cos (\beta)+2-\sin (\beta))}{\pi} \cdot \Delta \mathrm{L}\]

The pressure losses due to the sliding friction of the bed based on the normal stress carrying the weight distribution is now:

\[\ \Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s} \mathrm{f}}}{\mathrm{A}_{\mathrm{p}}}=\frac{\mu_{\mathrm{s} \mathrm{f}} \cdot \mathrm{F}_{\mathrm{n}}}{\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(-(\pi-\boldsymbol{\beta}) \cdot \cos (\beta)+\mathrm{2}-\sin (\beta))}{\pi}\]

This gives for the hydraulic excess gradient:

\[\ \mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s f}}}{\mathrm{A}_{\mathrm{p}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\frac{\mu_{\mathrm{s f}} \cdot \mathrm{F}_{\mathrm{n}}}{\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(-(\pi-\beta) \cdot \cos (\beta)+2-\sin (\beta))}{\pi}\]

In the case where the bed occupies the whole pipe cross section, β=π, this gives the so called plug gradient:

\[\ \mathrm{i}_{\mathrm{p} \operatorname{lug}}=\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(-(\pi-\pi) \cdot \cos (\pi)+2-\sin (\pi))}{\pi}=\frac{4}{\pi} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}}\]

This gives for the relative excess hydraulic gradient Erhg:

\[\ \mathrm{E}_{\mathrm{r h g}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{C}_{\mathrm{v s}}}=\mu_{\mathrm{s f}} \cdot \frac{\mathrm{2} \cdot(-(\pi-\beta) \cdot \cos (\beta)+2-\sin (\beta))}{(\beta-\sin (\beta) \cdot \cos (\beta))}\]

7.4.5 The Submerged Weight Approach

The submerged weight approach assumes that the sliding friction between the bed and the pipe wall results from the submerged weight and not from normal stress, see Figure 7.4-12. Scientifically this is incorrect, however in reality a sliding bed is not a solid object, but consists of many particles with their own behavior. The submerged weight of the bed Fw is given by:

\[\ \mathrm{F}_{\mathrm{w}}=\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{\mathrm{D}_{\mathrm{p}}^{2}}{\mathrm{4}} \cdot(\beta-\sin (\beta) \cdot \cos (\beta))\]

The pressure losses due to the sliding friction of the bed based on the submerged weight is now:

\[\ \Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s f}}}{\mathrm{A}_{\mathrm{p}}}=\frac{\mu_{\mathrm{s f}} \cdot \mathrm{F}_{\mathrm{w}}}{\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2}}=\mu_{\mathrm{s f}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(\beta-\sin (\beta) \cdot \cos (\beta))}{\pi}\]

This gives for the excess hydraulic gradient:

\[\ \mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s f}}}{\mathrm{A}_{\mathrm{p}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\frac{\mu_{\mathrm{s f}} \cdot \mathrm{F}_{\mathrm{w}}}{\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\mu_{\mathrm{sf}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \frac{(\beta-\sin (\beta) \cdot \cos (\beta))}{\pi}=\mu_{\mathrm{sf}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{s}}\]

In the case where the bed occupies the whole pipe cross section, β=π, this gives the so called plug gradient:

\[\ \mathrm{i}_{\mathrm{p l u g}}=\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}} \cdot \frac{(\pi-\sin (\pi) \cdot \cos (\pi))}{\pi}=\mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}}\]

This gives for the relative excess hydraulic gradient Erhg:

| \[\ \mathrm{E}_{\mathrm{r h g}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}}}=\mu_{\mathrm{sf}} \quad\text{ and }\quad \mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}}\] |

7.4.6 Summary

In the case when the relative concentration Cvr=Cvs/Cvb or Cvr=Cvt/Cvb equals 1, the hydraulic gradient equals the plug resistance, according to:

|

Wilson hydrostatic approach |

Normal stress approach |

Submerged weight approach |

| \(\ \mathrm{i}_{\mathrm{p l u g}}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{C}_{\mathrm{v b}}\) | \(\ \mathrm{i}_{\text {plug }}=\frac{4}{\pi} \cdot \mu_{\text {sf }} \cdot \mathrm{R}_{\text {sd }} \cdot \mathrm{C}_{\mathrm{v b}}\) | \(\ \mathrm{i}_{\mathrm{p} \mathrm{l u g}}=\mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}}\) |

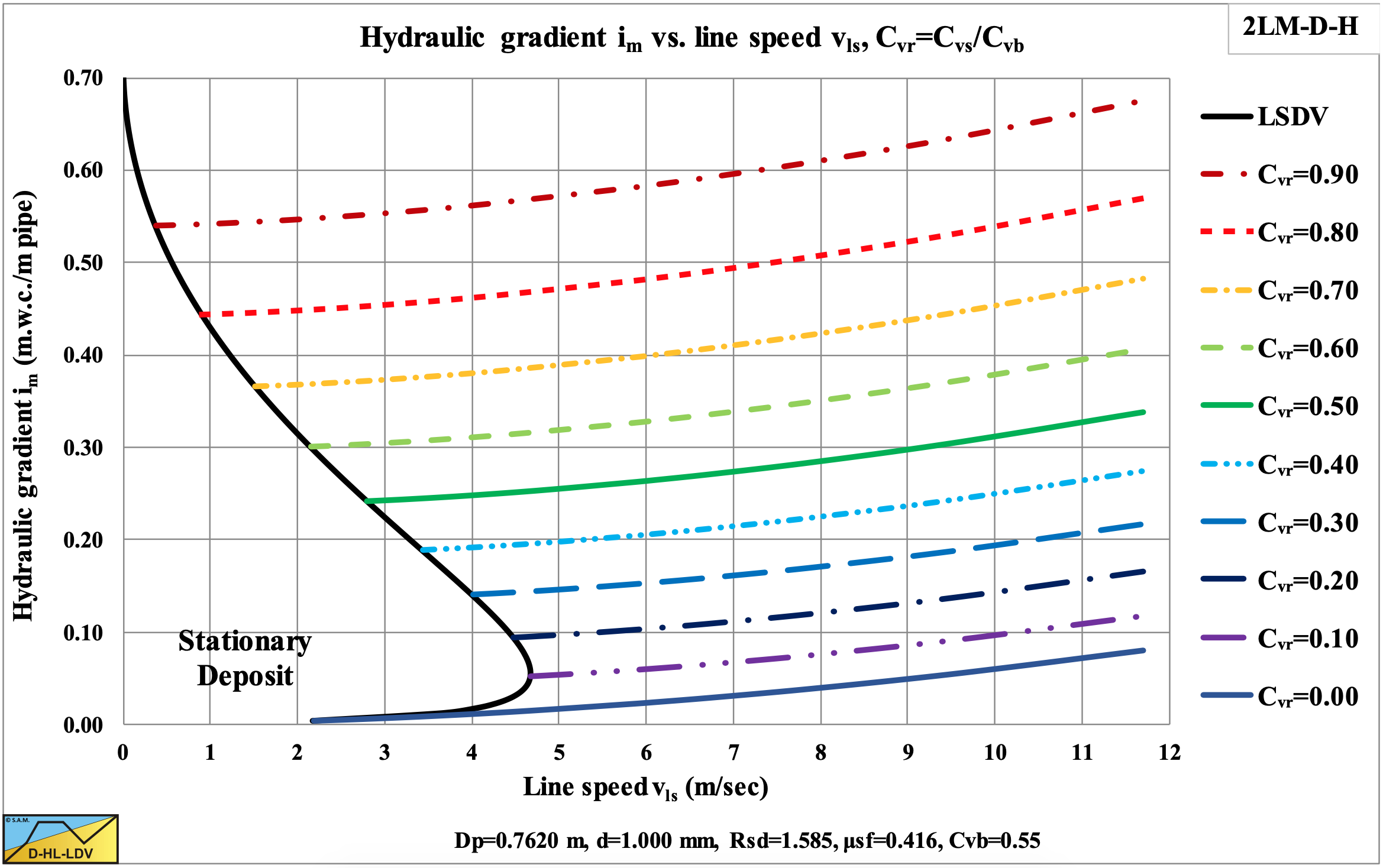

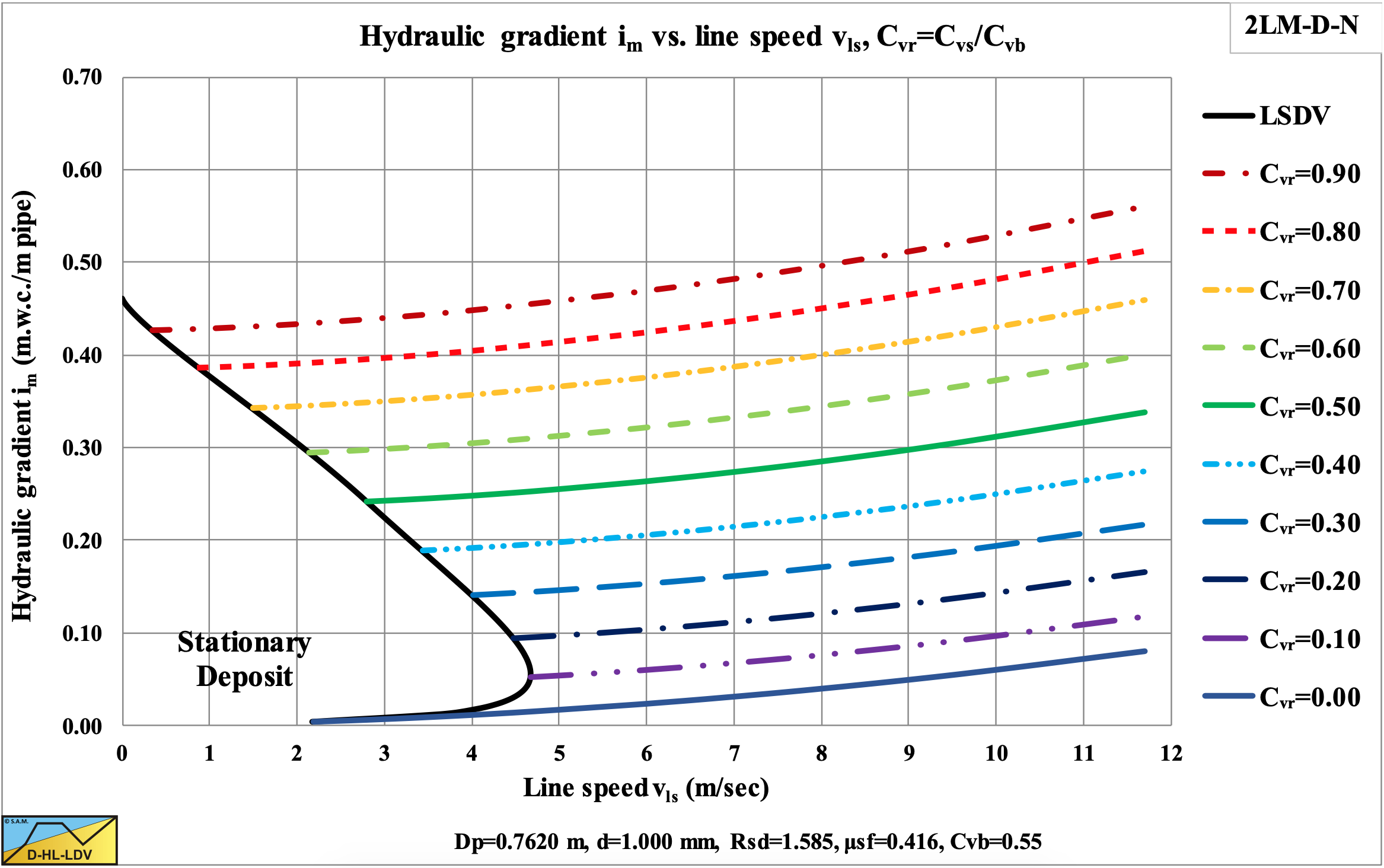

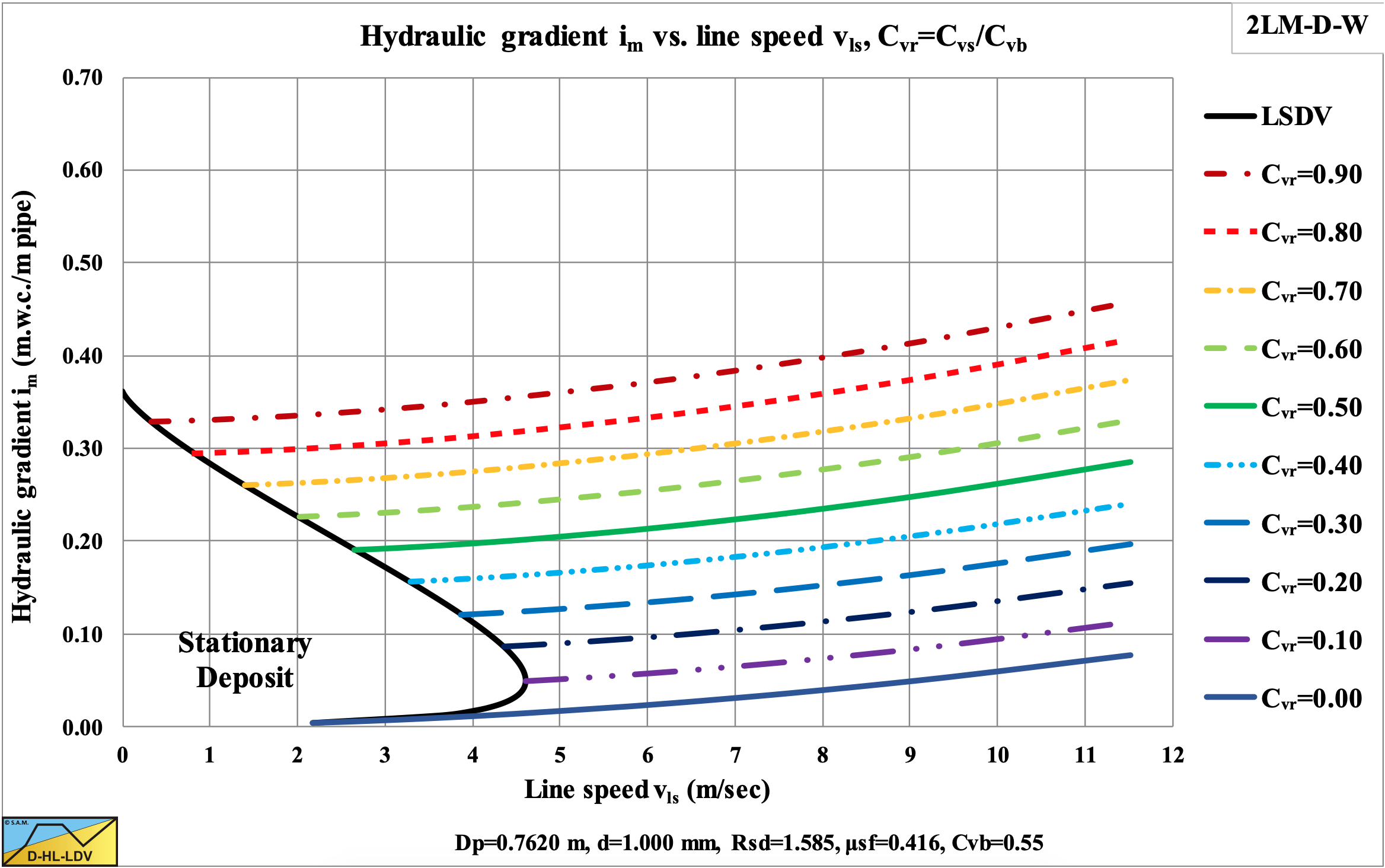

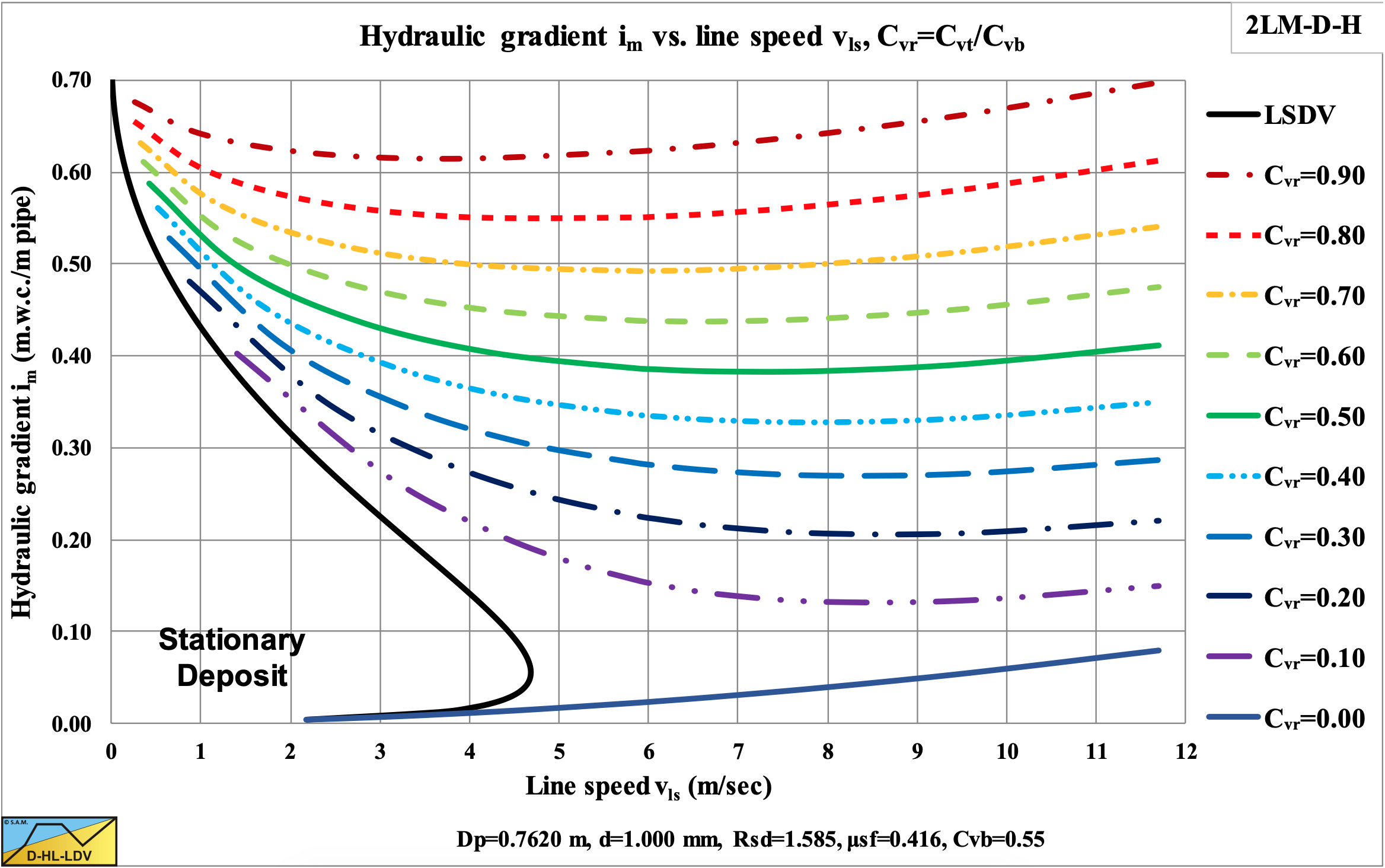

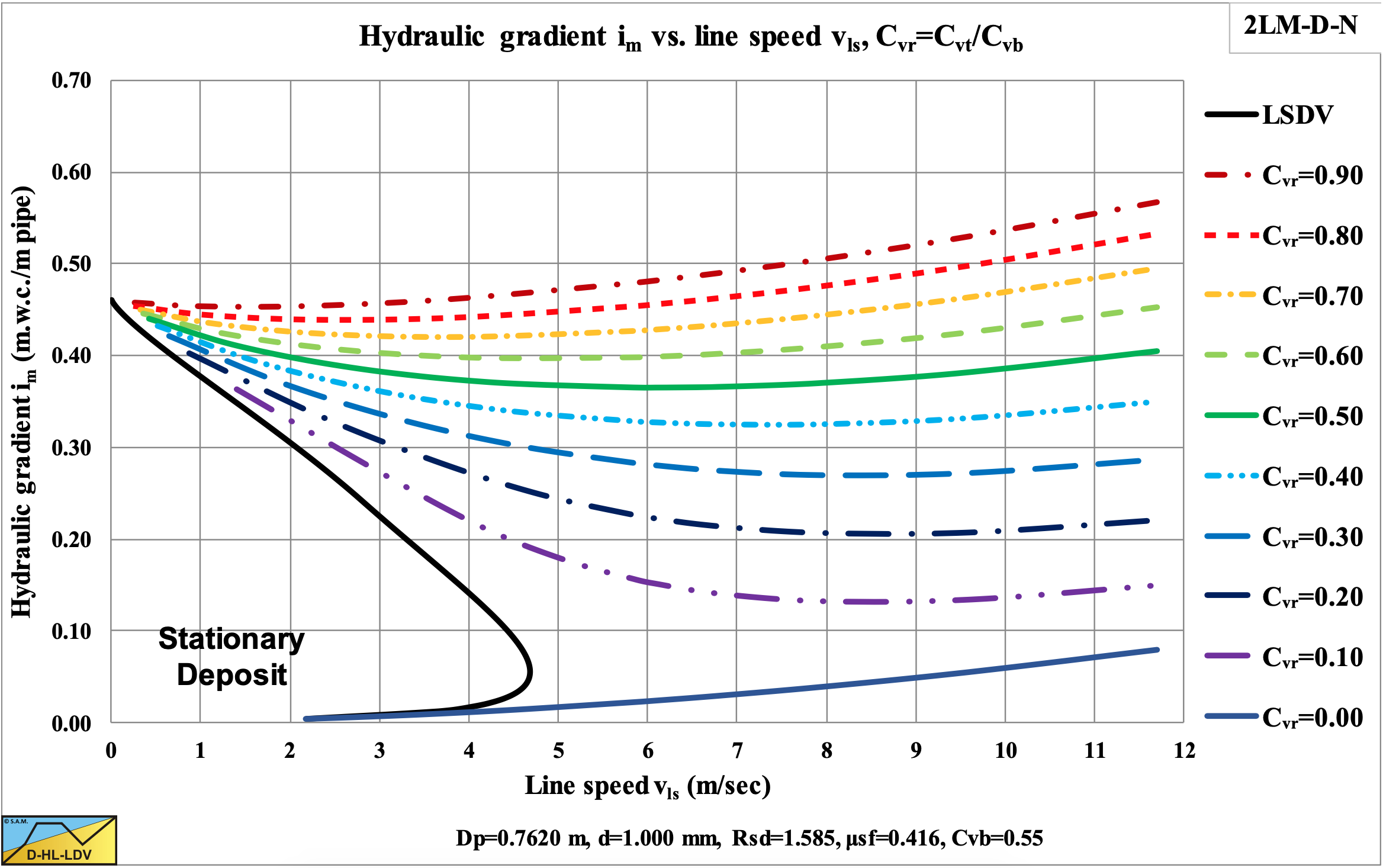

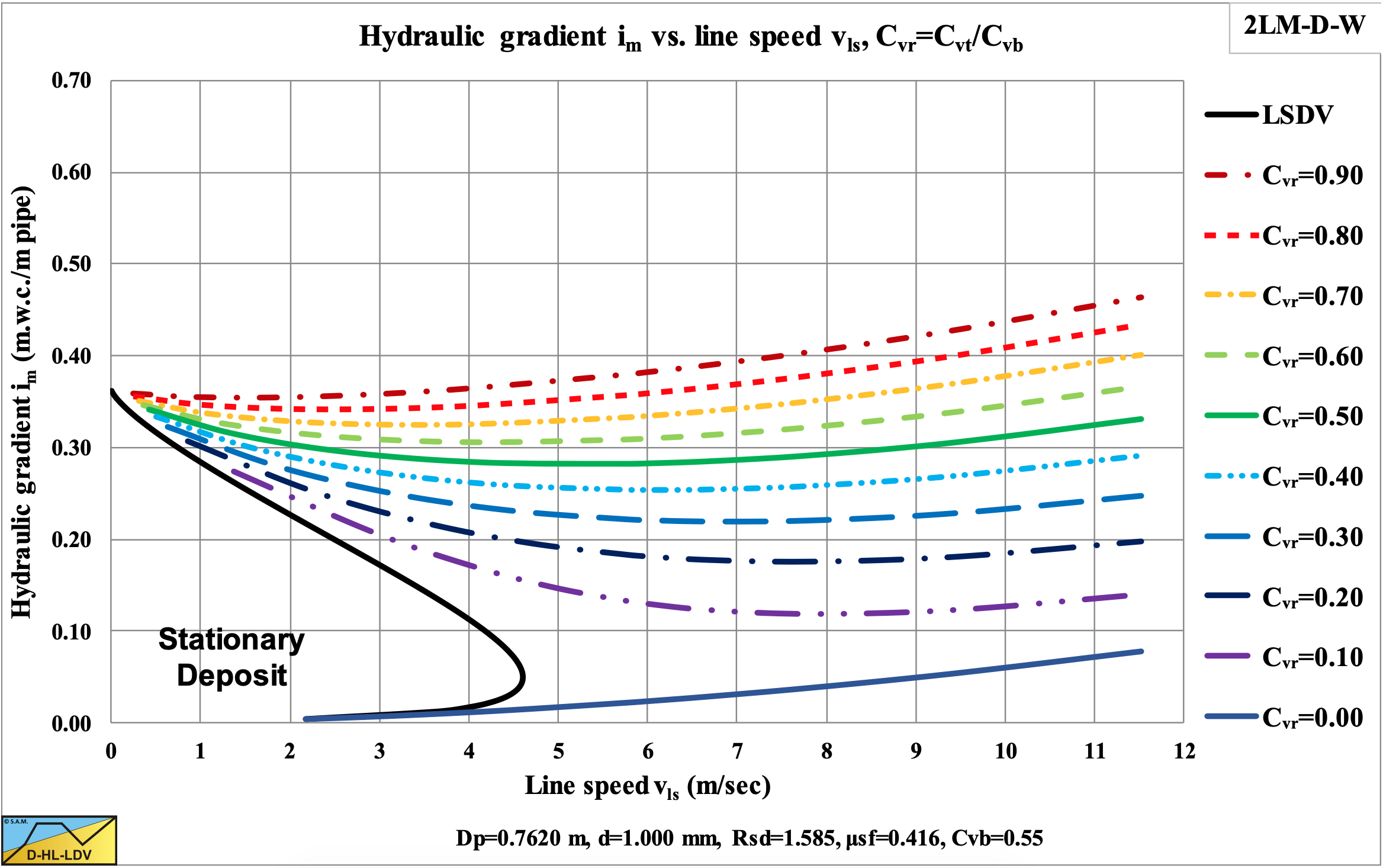

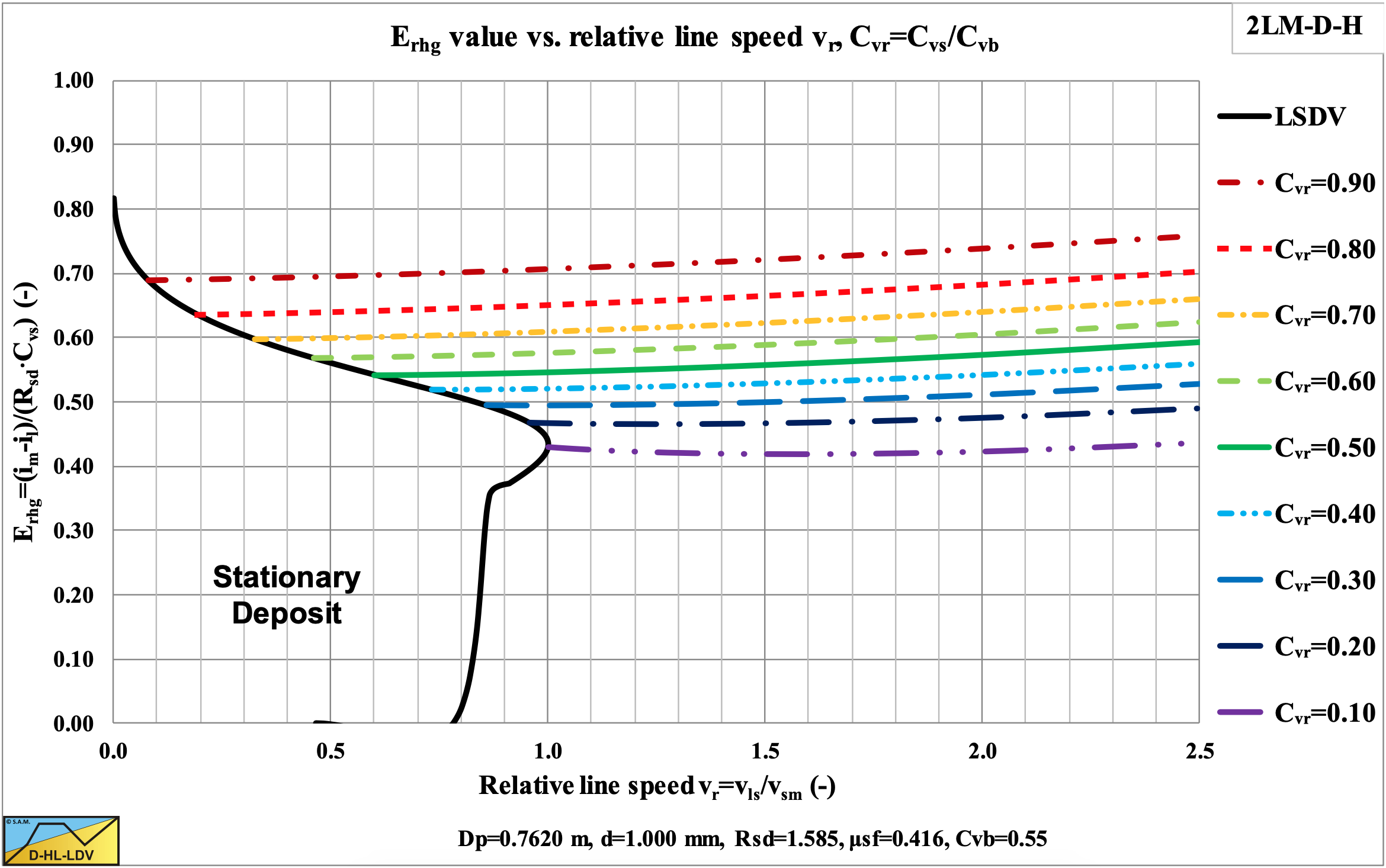

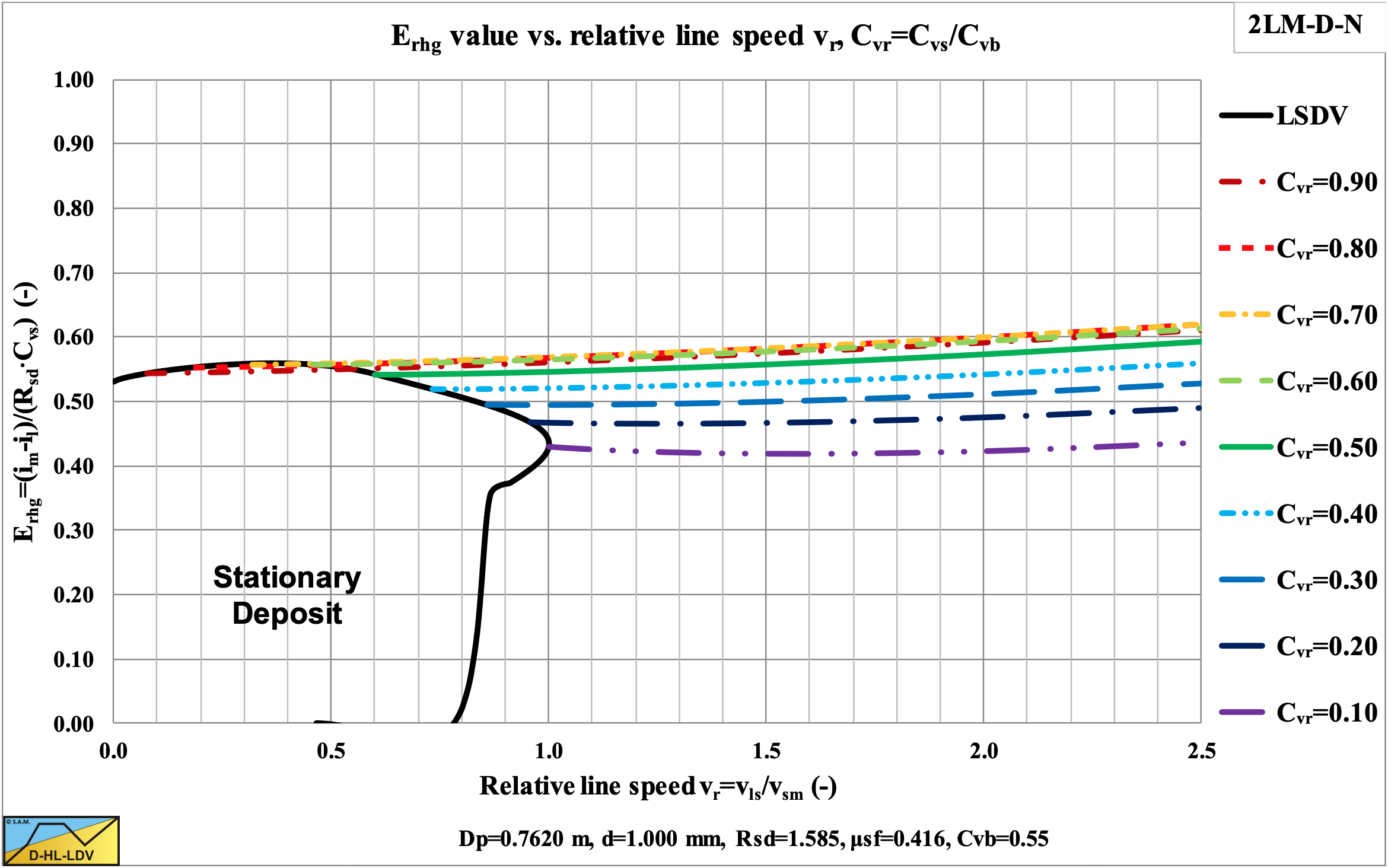

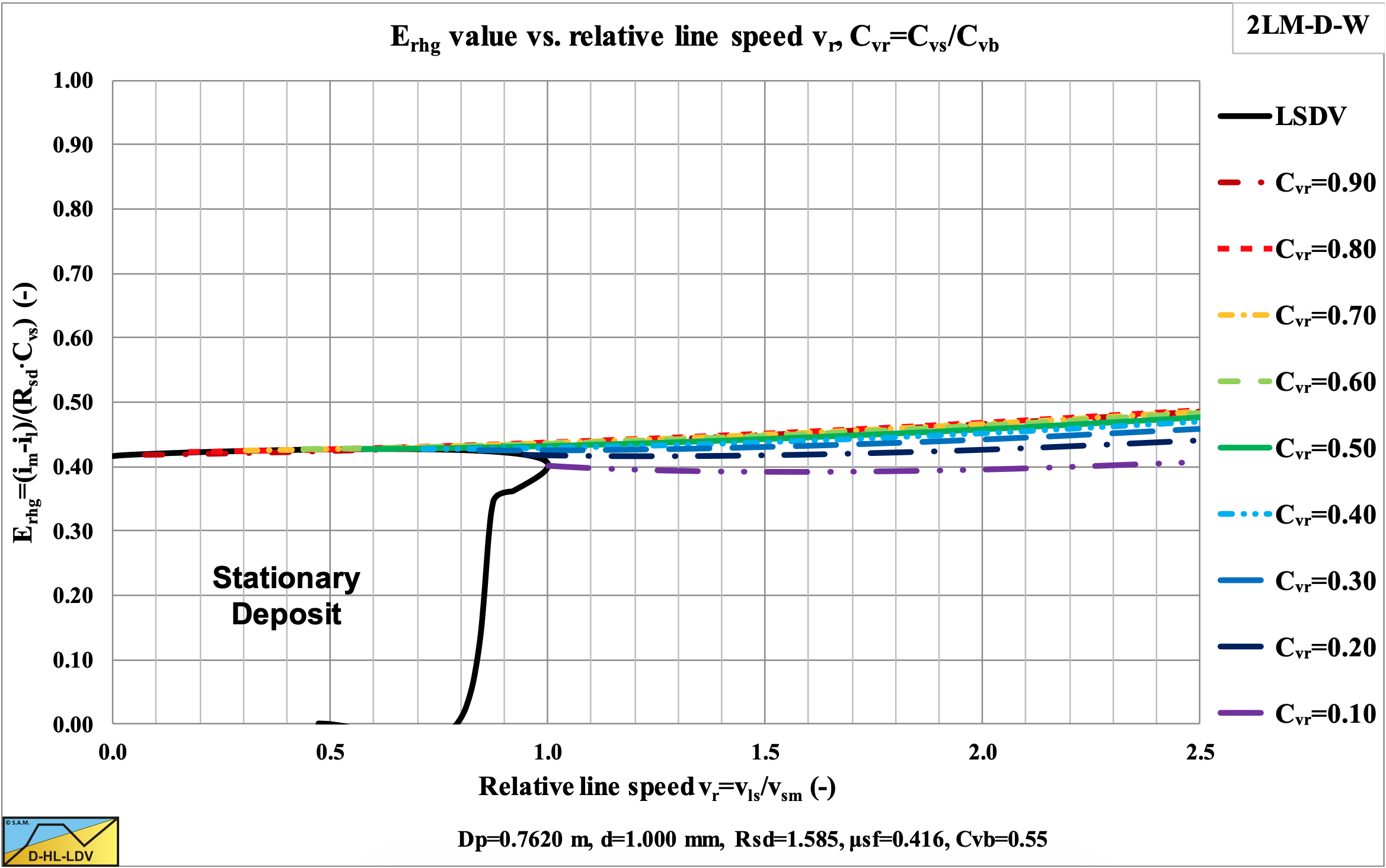

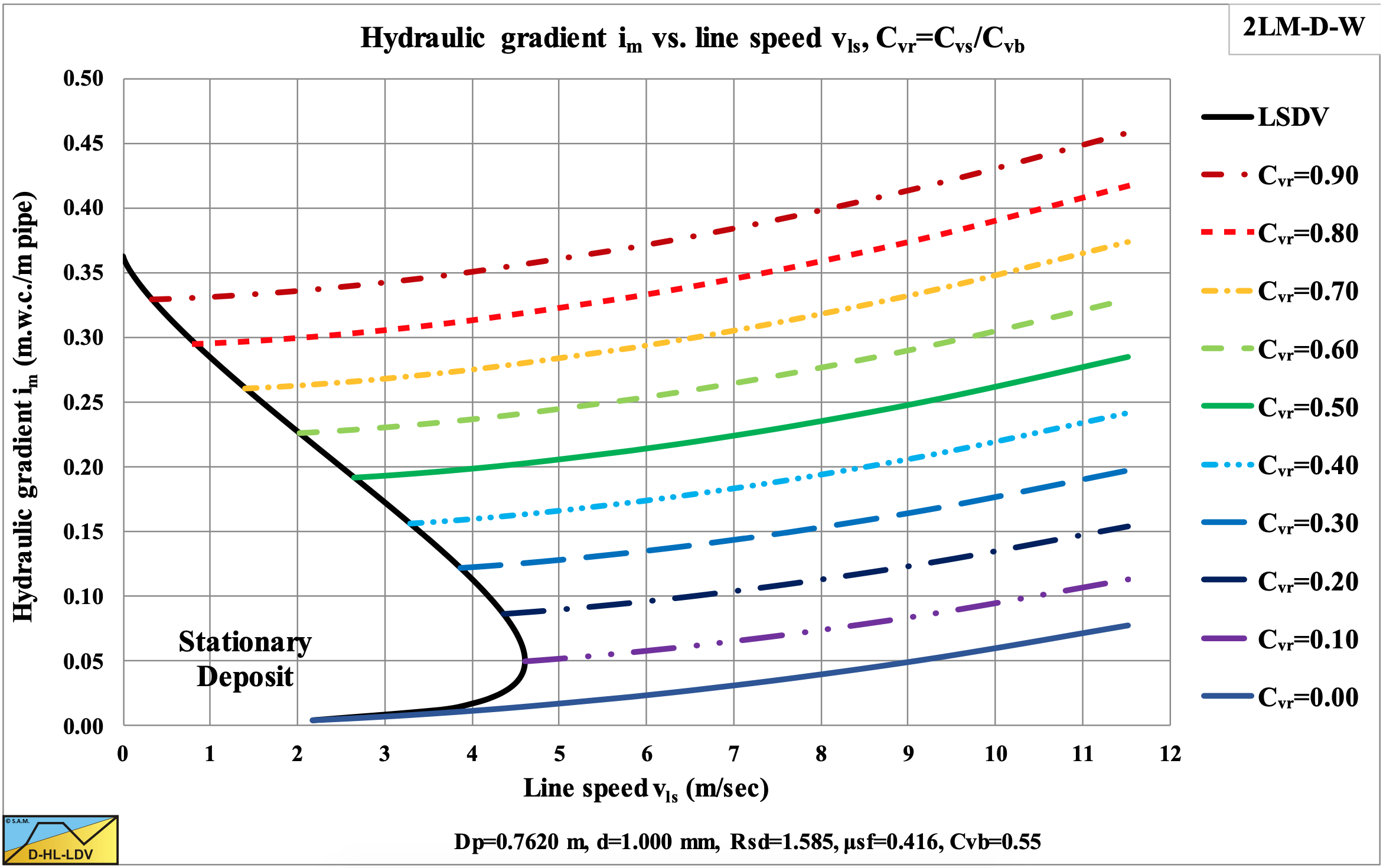

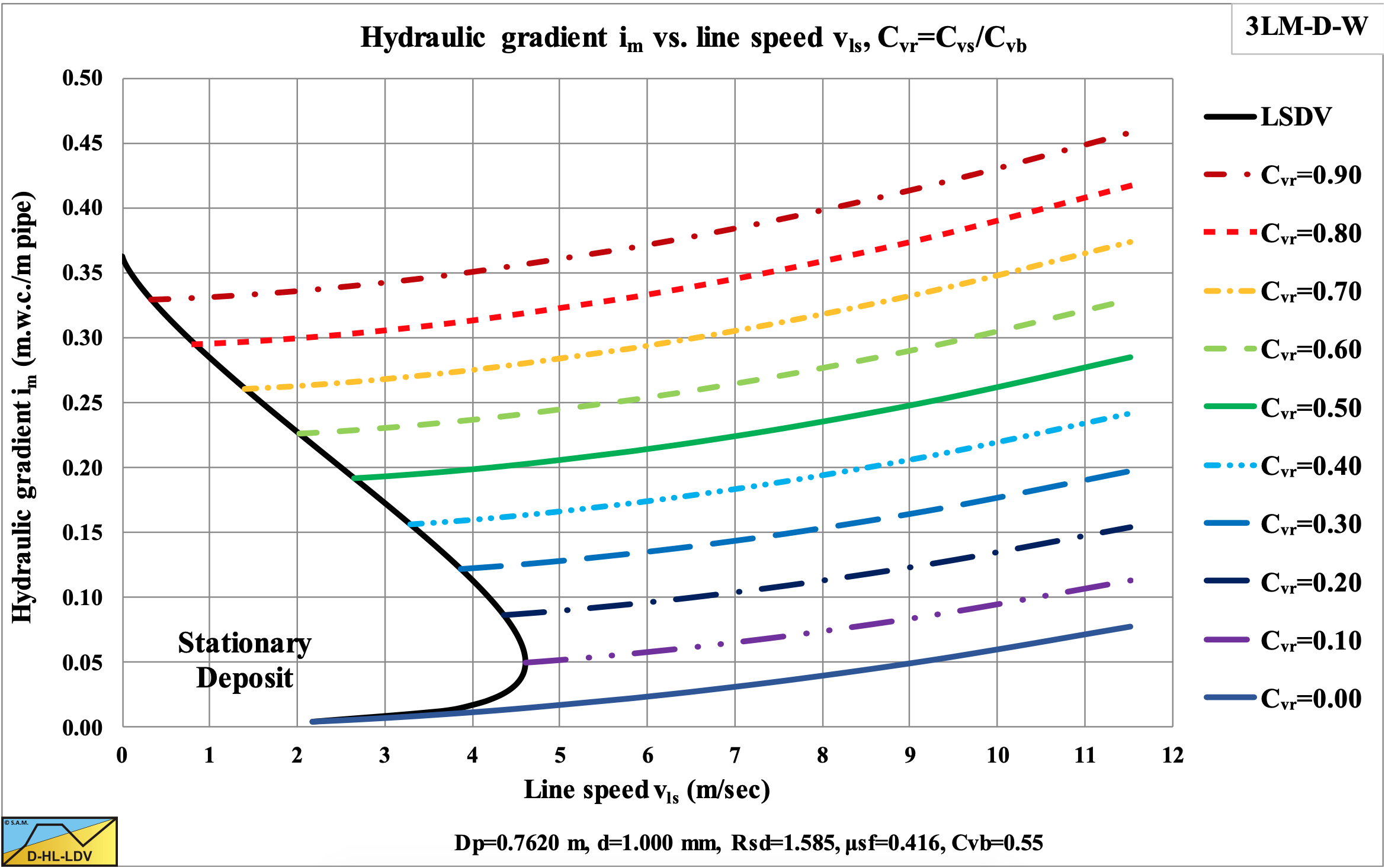

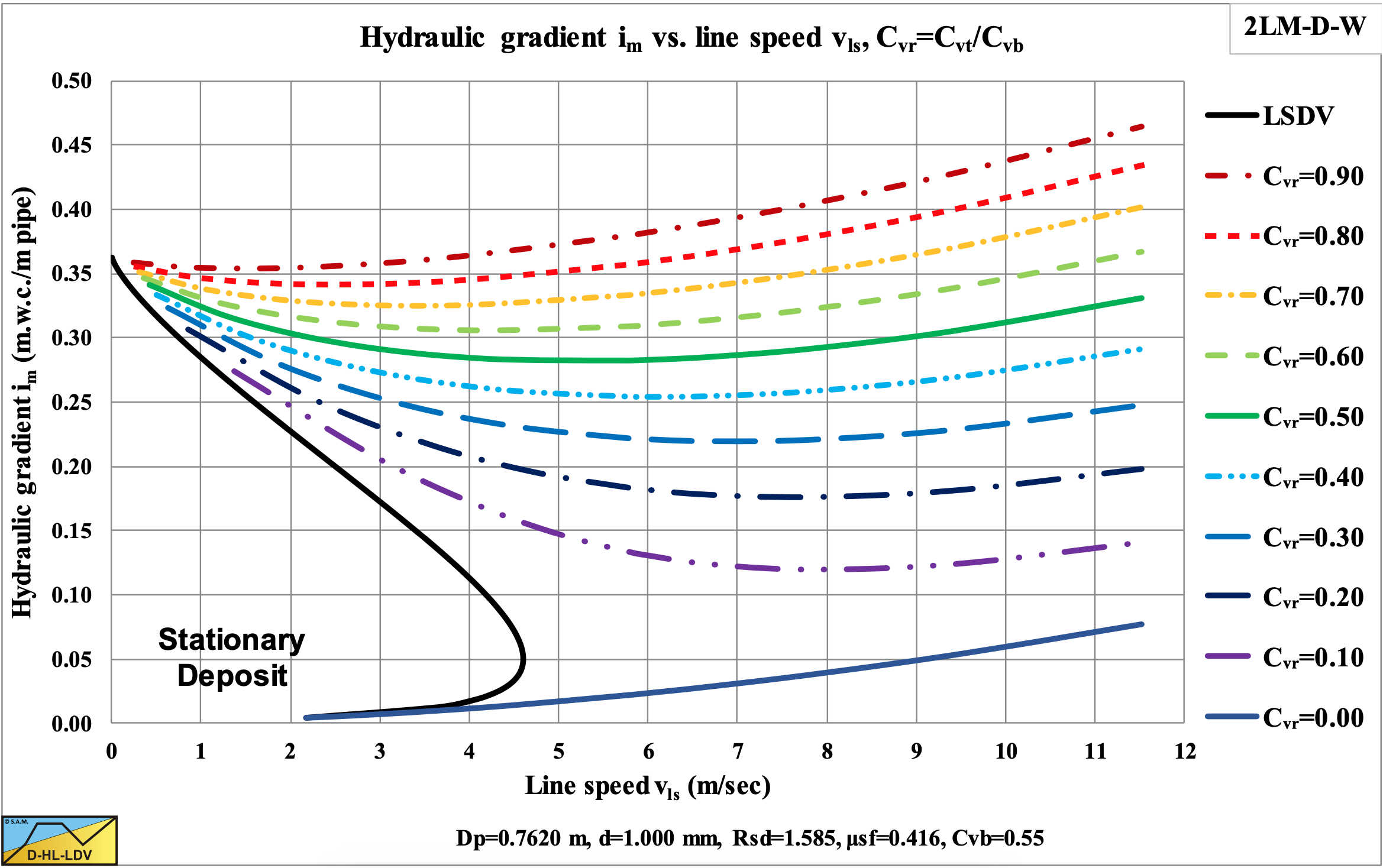

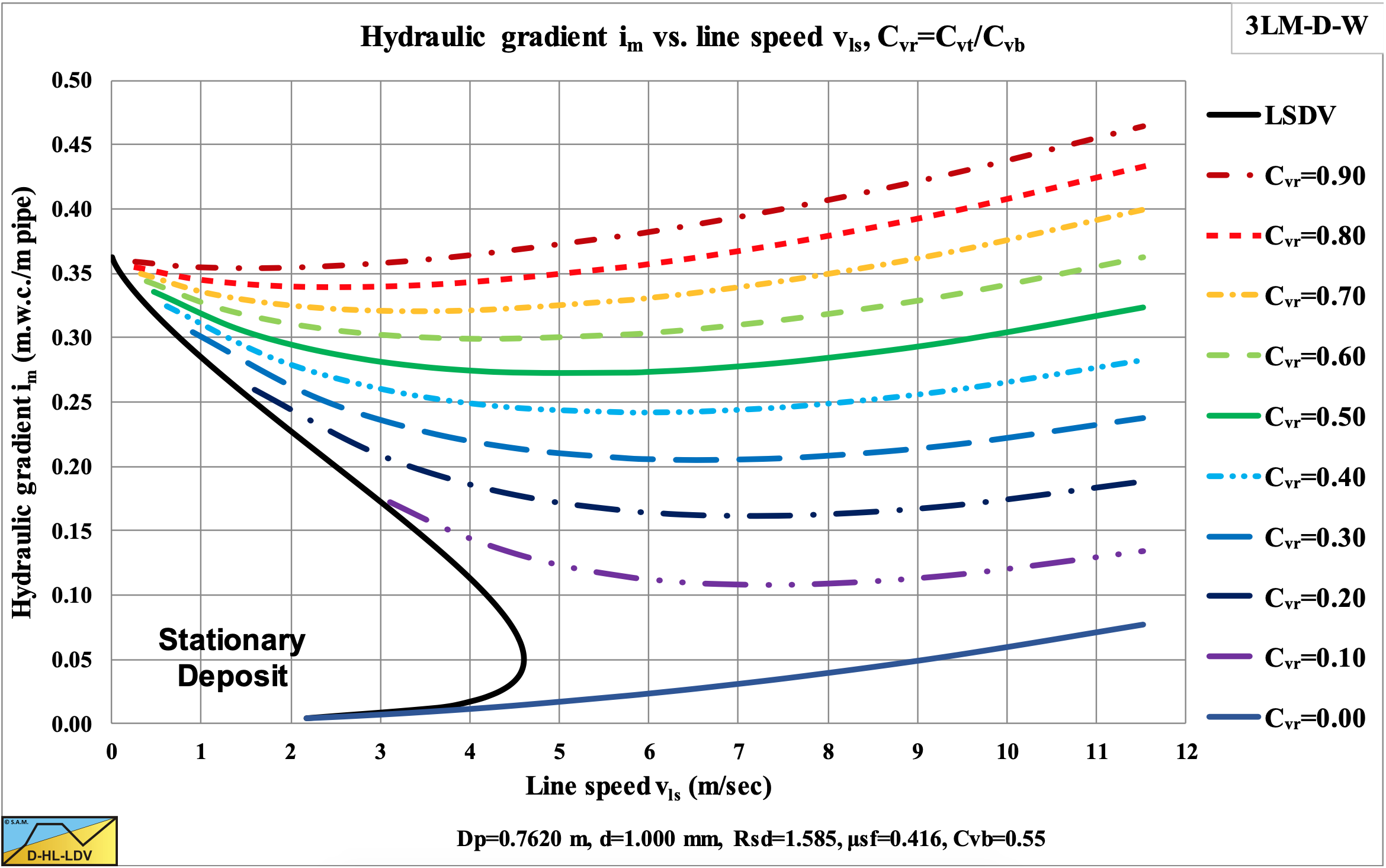

There are a number of approaches to determine the sliding friction force on a moving bed. These approaches are the original Wilson (1992) approach, based on the assumption that there is a hydrostatic pressure between the bed and the pipe wall. This assumes a pressure distribution as if the bed were a fluid, but the pipe wall friction based on the sliding coefficient of friction. The second approach assumes that the vertical component of the normal stress has to carry the weight of the bed. This approach is similar to the Wilson (1992) approach for pipes filled up to 50% with sand. Above 50% there is a significant difference between the two approaches, as the portion of the bed above the centerline of the pipe contributes weight but no friction. Another approach is the active/passive soil resistance approach, but it only gives solutions if the factor K=1, making it equivalent to the second approach. The third approach assumes that the sliding friction force is the result of the submerged weight of the bed times a sliding friction coefficient. In all 3 cases, solving the force equilibrium equations result in a Limit of Stationary Deposit Velocity curve (here defined as the velocity at which the bed starts sliding) and resistance curves based on constant spatial volumetric concentration. Figure 7.4-13, Figure 7.4-14 and Figure 7.4-15 give the hydraulic gradients for the 3 approaches for the constant spatial volumetric concentration curves. It is clear from these figures that the Wilson hydrostatic approach gives the highest hydraulic gradients (maximum factor 2 normal force to weight ratio), followed by the normal force carrying the weight approach (maximum factor 1.3 normal force to weight ratio), followed by the submerged weight approach (maximum factor 1 normal force to weight ratio).

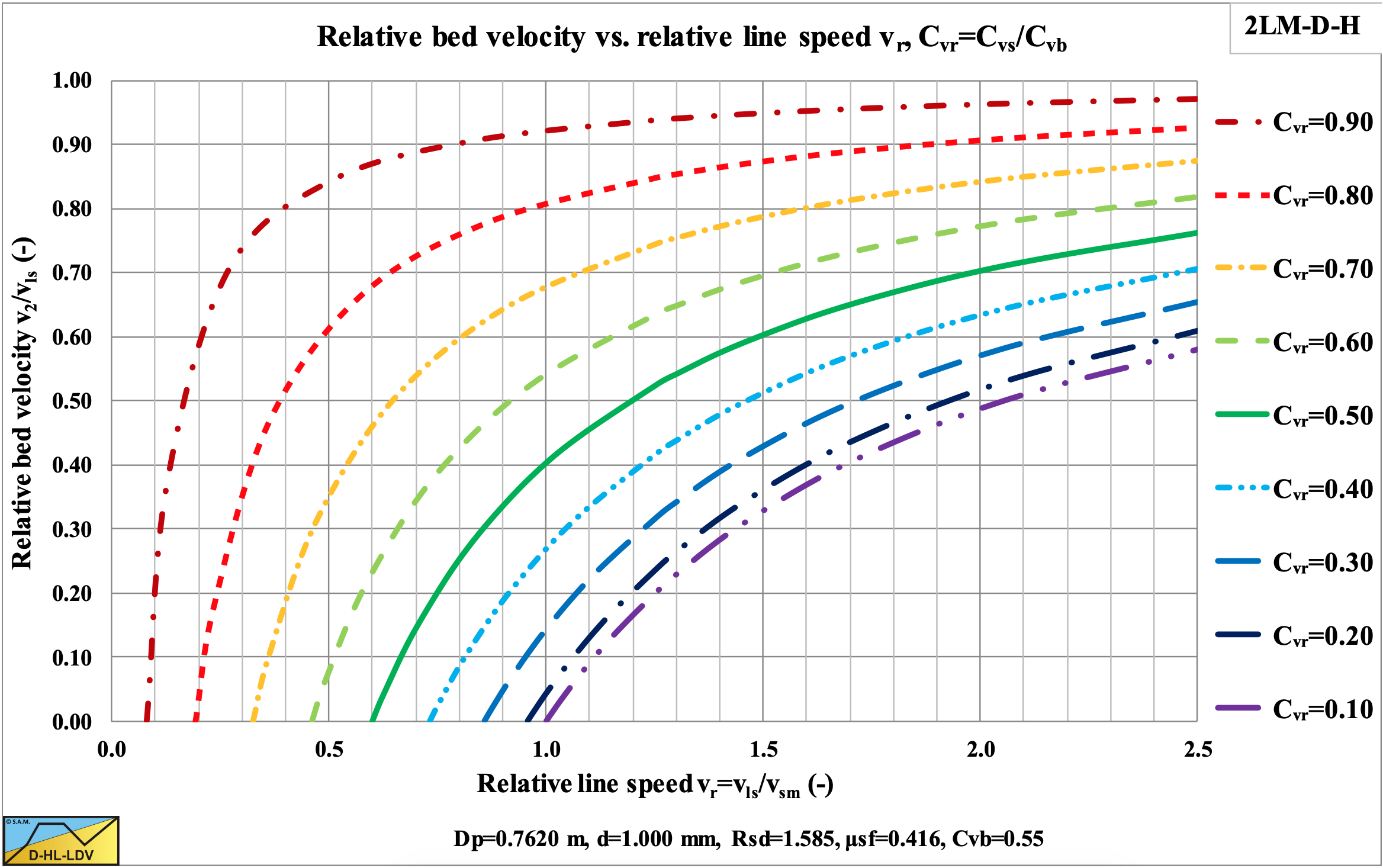

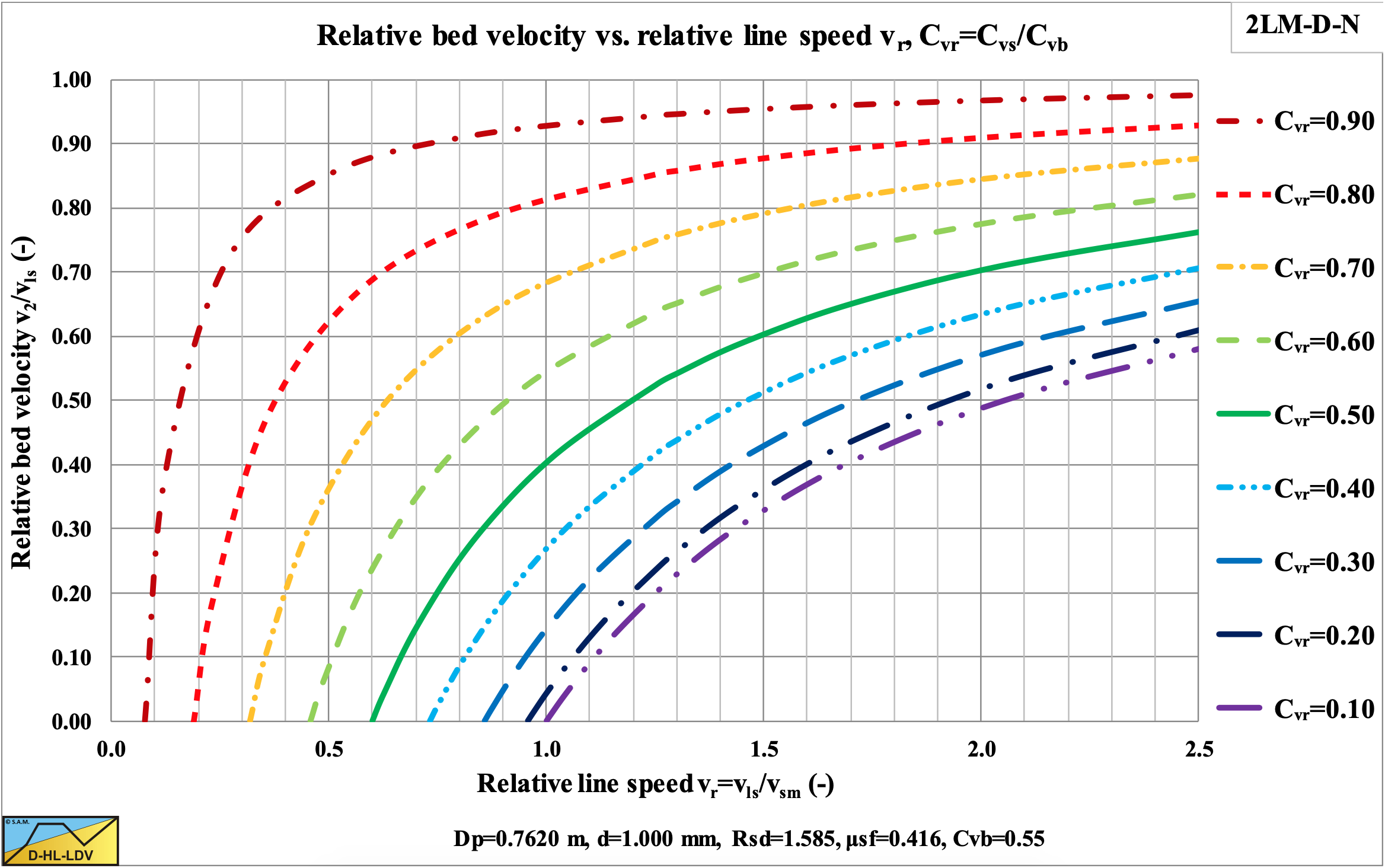

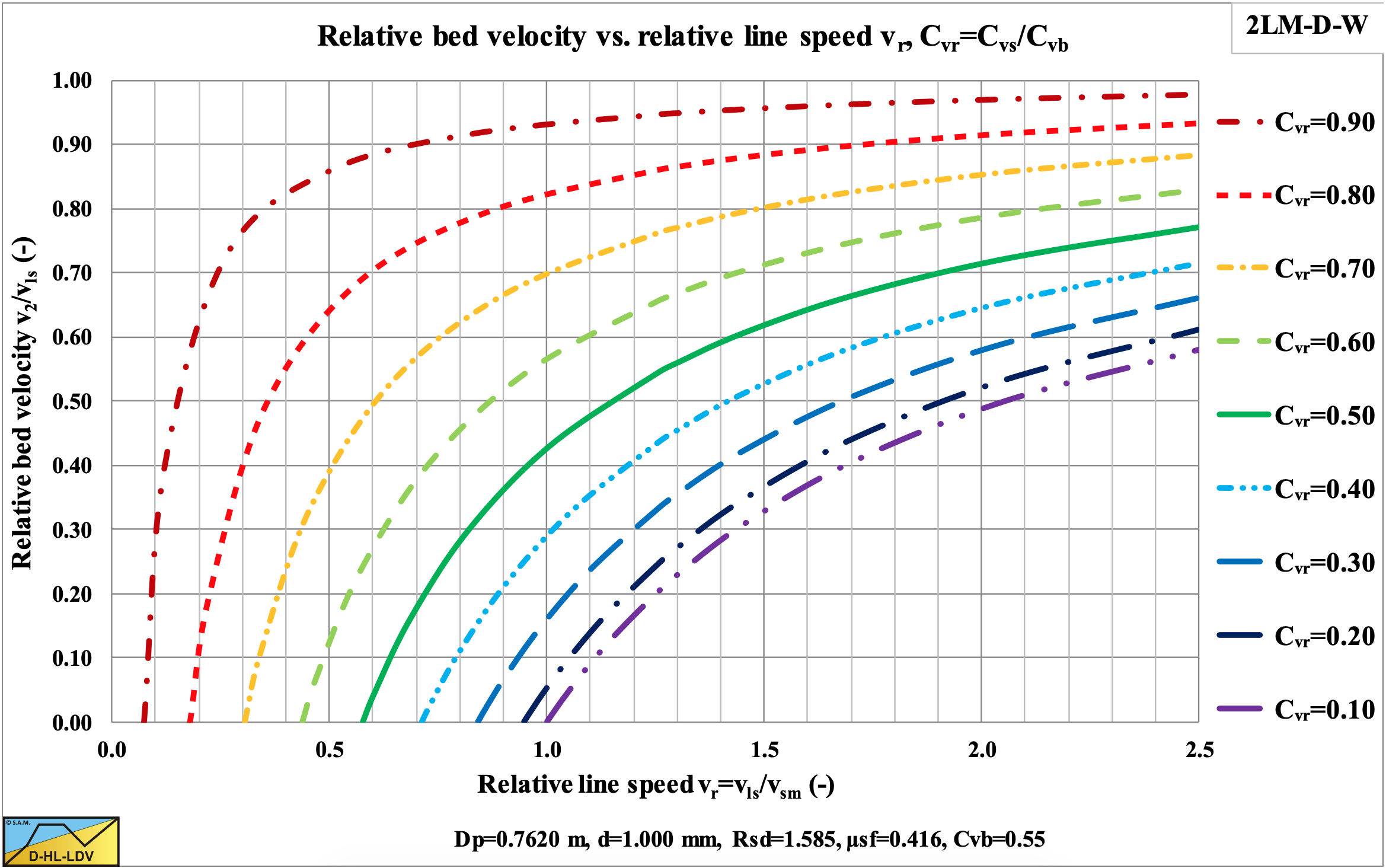

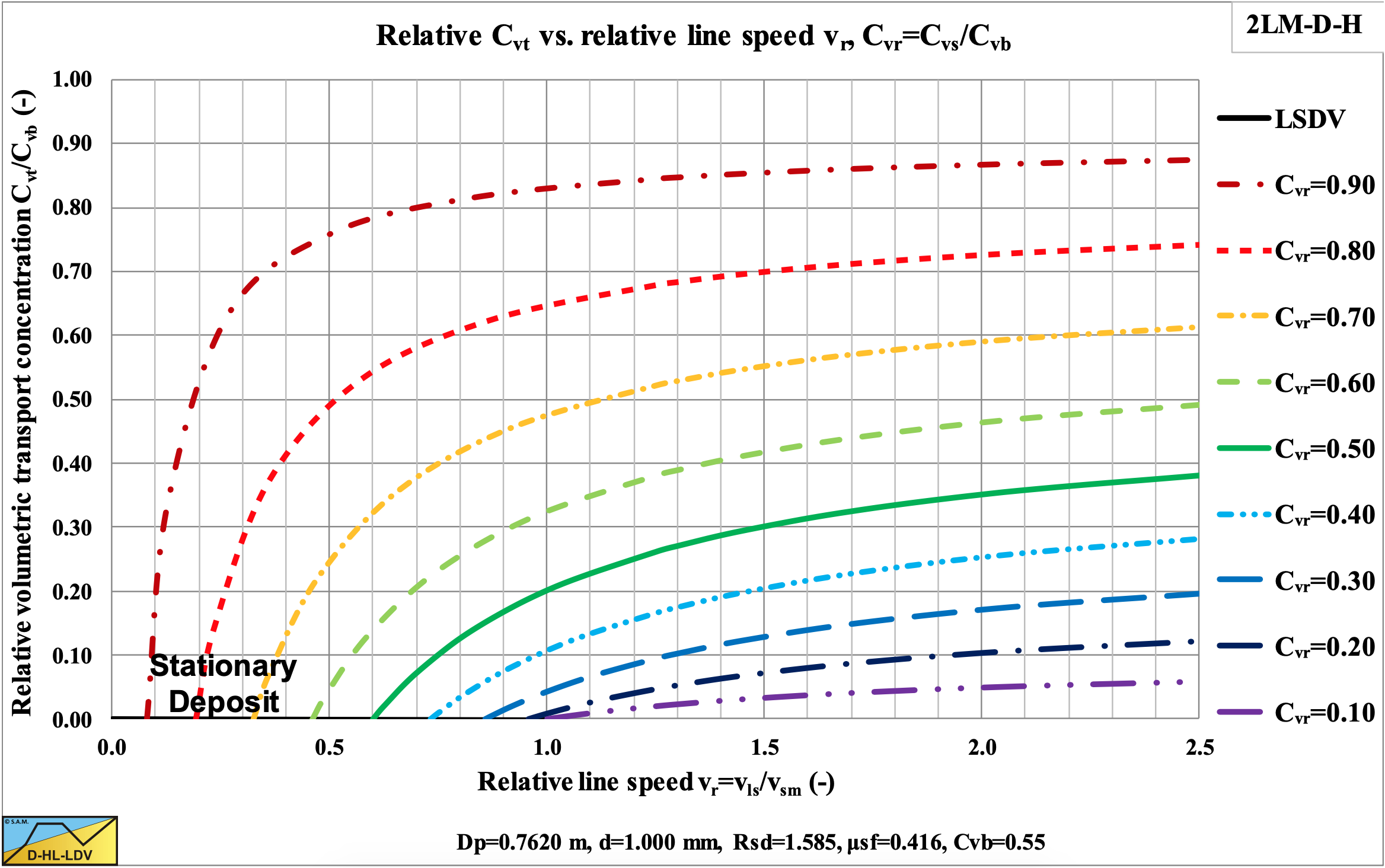

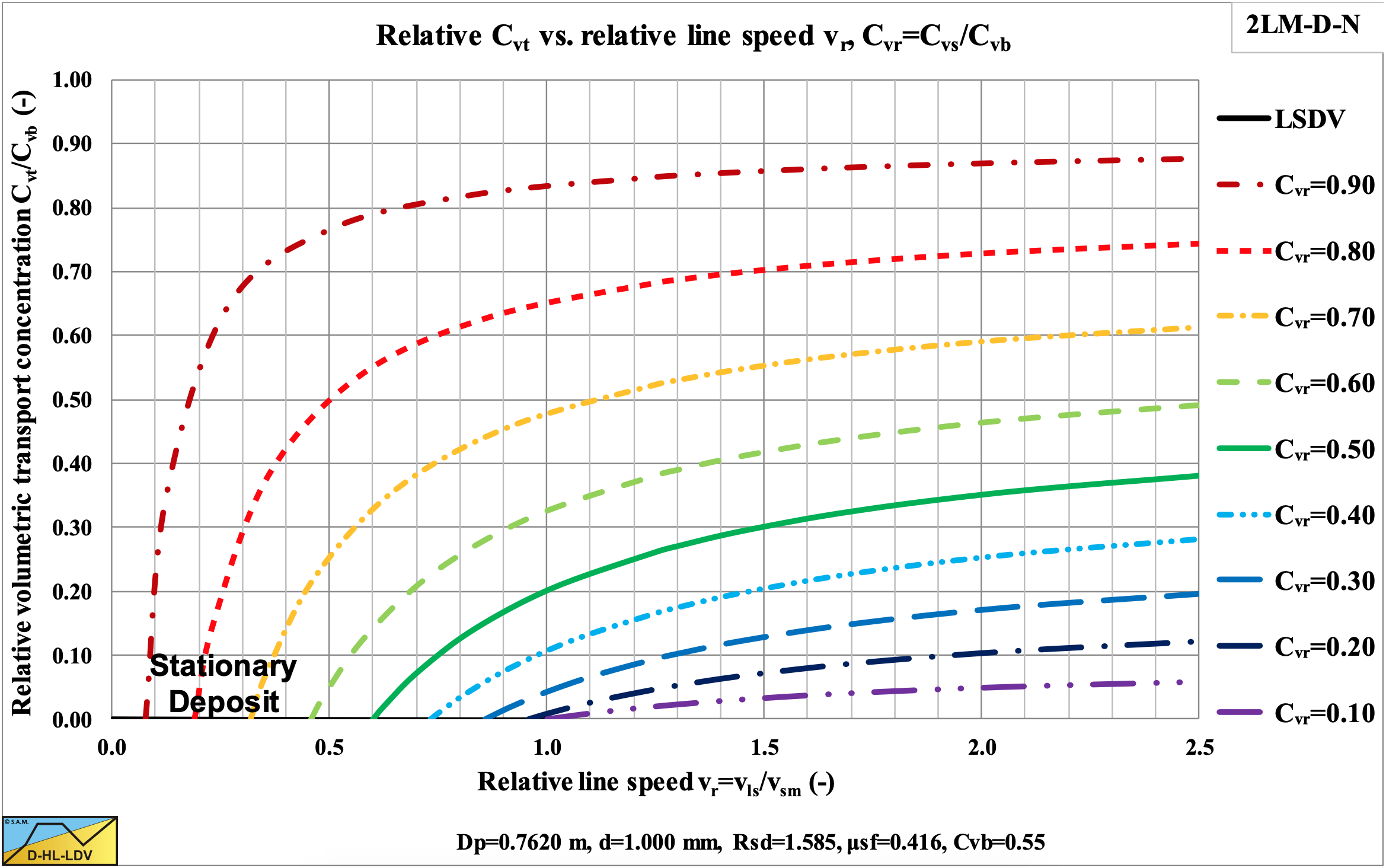

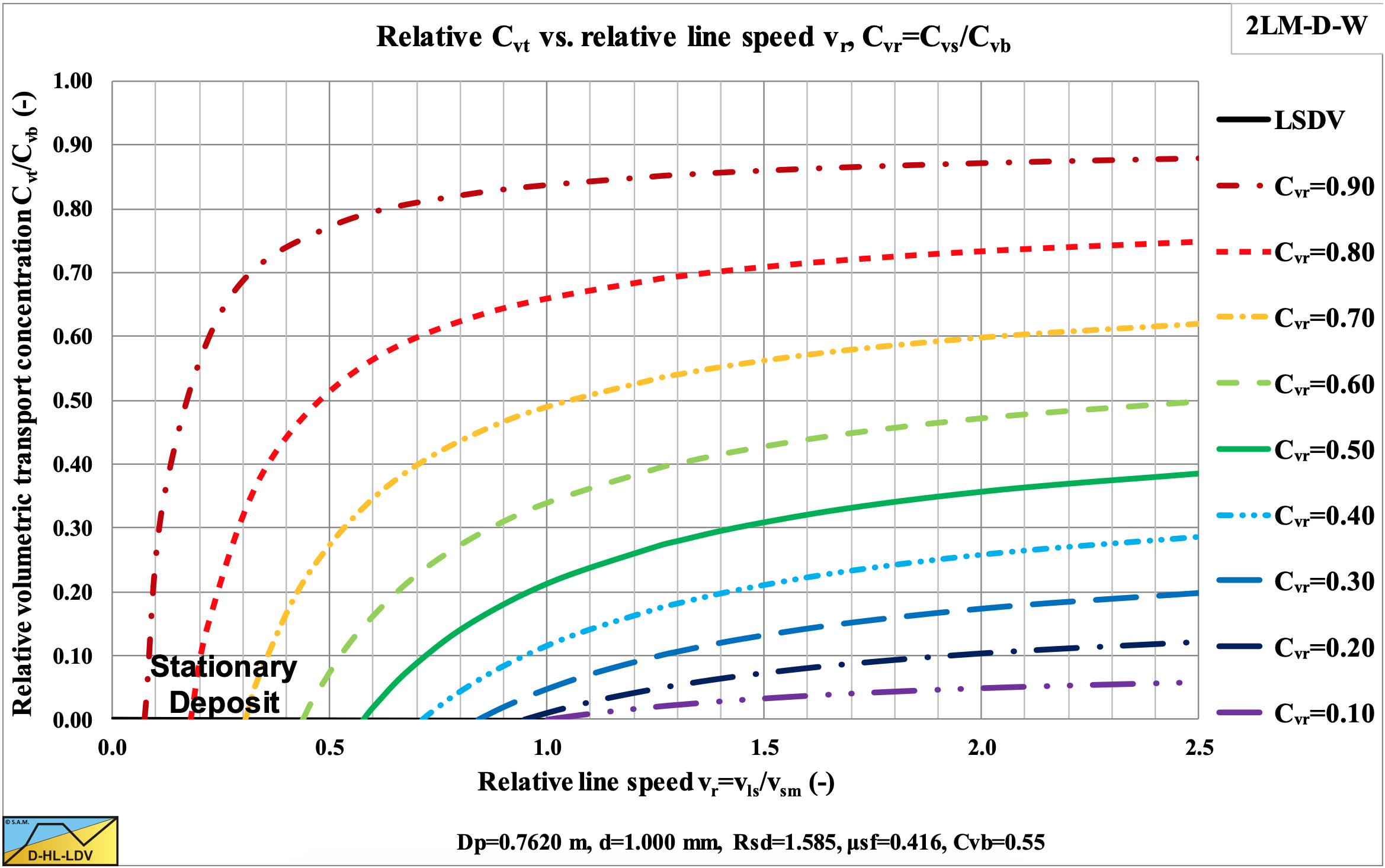

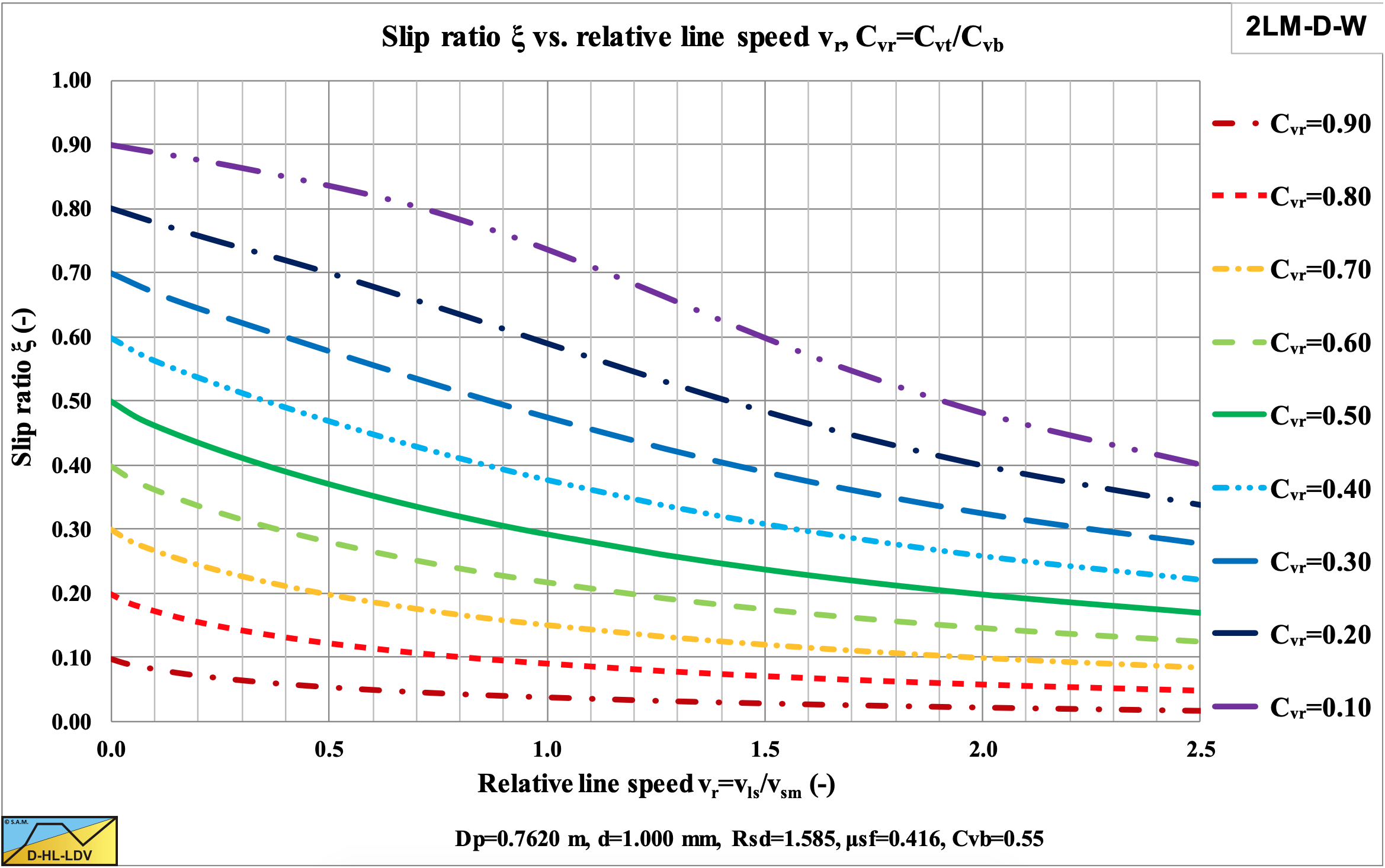

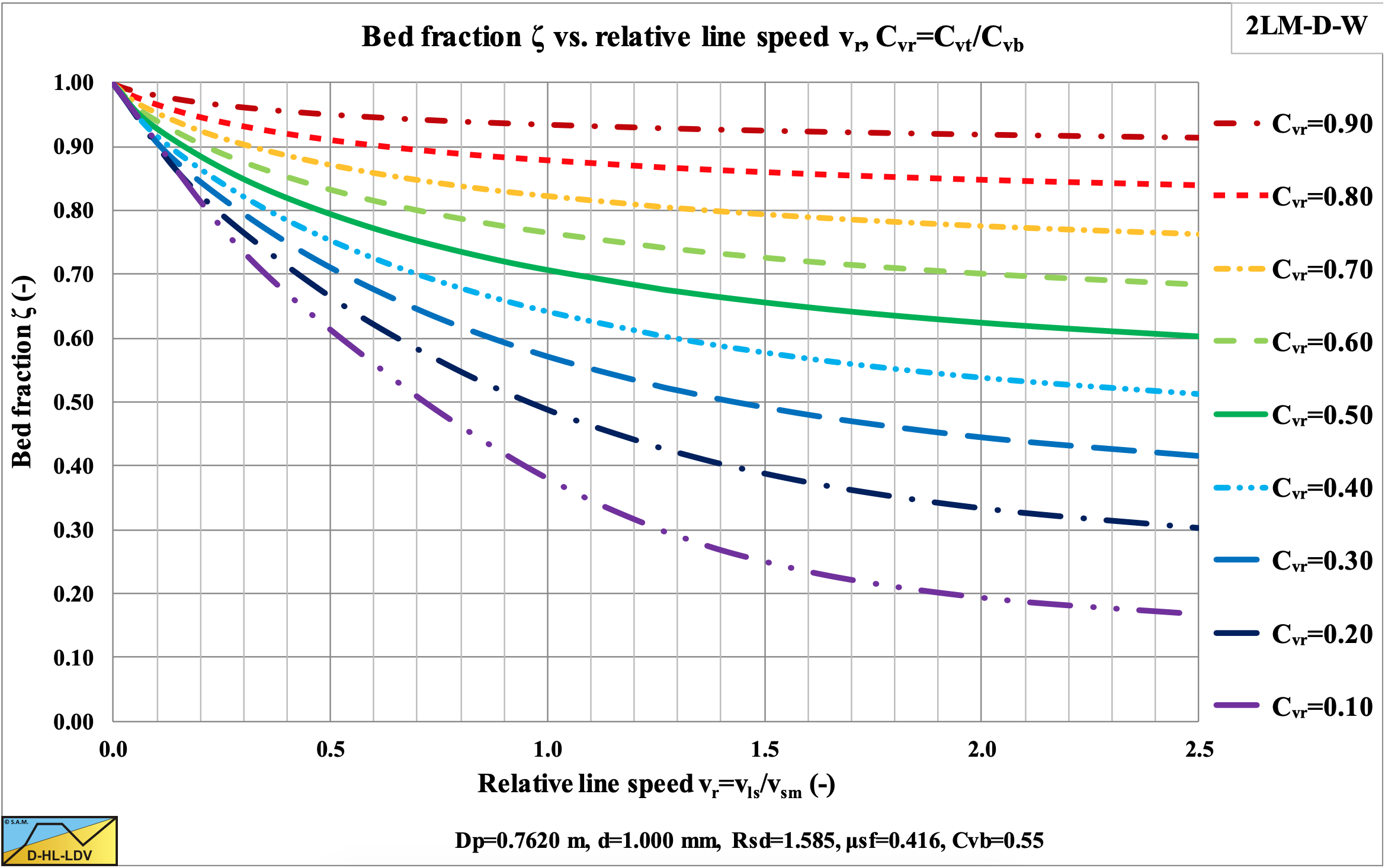

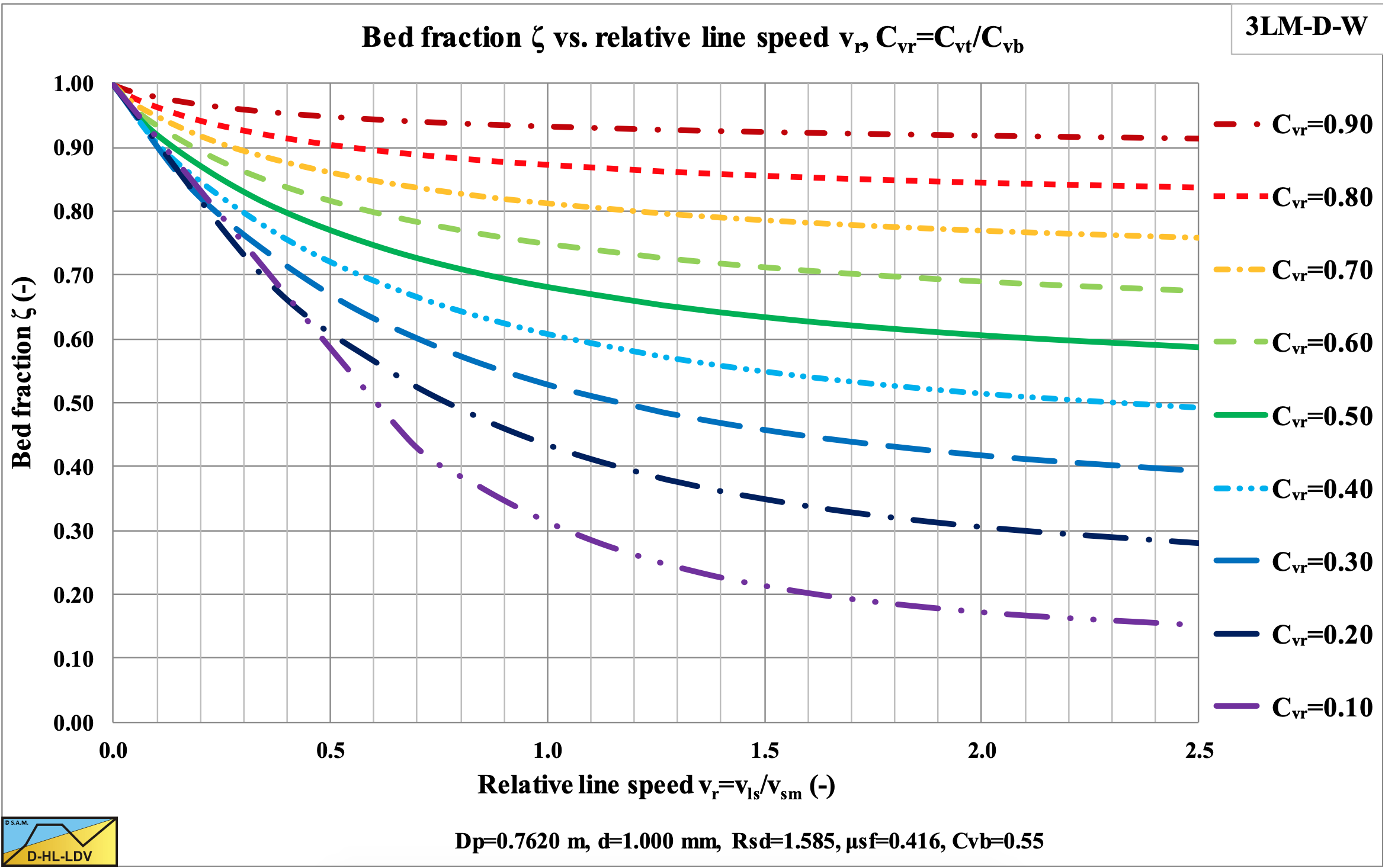

Based on the force equilibrium equations, the velocity of the sliding bed is determined and shown in Figure 7.4-16, Figure 7.4-17 and Figure 7.4-18 for the 3 approaches. Once the bed velocity is known, the delivered or transport concentration can be determined as is shown in Figure 7.4-19, Figure 7.4-20 and Figure 7.4-21. Now the transport concentrations are determined, hydraulic gradient curves for constant delivered or transport concentration can be determined by interpolation. Figure 7.4-22, Figure 7.4-23 and Figure 7.4-24 show the hydraulic gradients as a function of the delivered volumetric concentration. The curves never touch the Limit Deposit Velocity curves, since the delivered volumetric concentration is always zero on these curves, due to the assumption that there is only transport of particles if the bed is sliding. Figure 7.4-25, Figure 7.4-26 and Figure 7.4-27 show the relative excess hydraulic gradient (Erhg) as a function of the spatial concentration. In the case of the submerged weight approach, this gives an almost constant Erhg very close to the sliding friction coefficient μsf.

Now which approach to use? If there is only transport through a sliding bed, the second approach should be applied. The Wilson hydrostatic approach overestimates the total normal force between the bed and the pipe wall if the pipe is filled with more than 50% by the bed, by assuming both horizontal and vertical components of normal stress for the entire perimeter of the pipe filled by the bed. The normal stress carrying the weight of the bed approach gives a correct value for the normal force in this case. In practice however the pipe will never be filled more than 50% (this would cause plugging) so for practical applications the Wilson hydrostatic approach is suitable.

In practice however the sand transport will not only take place through a sliding bed only. If the velocity above the bed is high enough, sheet flow will occur. Sheet flow is a layer of fast moving particles on the top of the bed. The weight of these particles is still transferred to the bed and will contribute to the sliding friction force, but this layer of sheet flow will not result in sliding friction where it is in contact with the pipe wall. Of course, the higher the line speed, the thicker the layer of sheet flow (Miedema (2014)). This thicker layer of sheet flow implies a thinner bed and larger part of the solids that do not contribute to normal stresses on the wall, so the more the submerged weight approach is more valid.

Figure 7.4-13 to Figure 7.4-27 show a comparison between the 3 methods for the wall friction, using the Miedema & Matousek (2014) approach for the bed friction.

7.4.7 The 3 Layer Model

In the 2 layer model only the bed is transporting solids with the bed velocity. In the 3 layer model, the top of the bed is moving with a higher velocity as a sheet flow layer, so it is expected that the total transport of solids is larger in the 3LM compared to the 2LM.

Pugh & Wilson (1999) found a relation for the velocity at the top of the sheet flow layer with a stationary bed. This relation is modified here for a sliding bed, giving:

\[\ \mathrm{U}_{\mathrm{H}}=\gamma \cdot \mathrm{u}_{*}+\mathrm{v}_{2}=\gamma \cdot \sqrt{\frac{\lambda_{\mathrm{1} 2}}{\mathrm{8}}} \cdot\left(\mathrm{v}_{\mathrm{1}}-\mathrm{v}_{2}\right)+\mathrm{v}_{\mathrm{2}}=\mathrm{U}_{\mathrm{H} 0}+\mathrm{v}_{2} \quad\text{ with: }\quad \gamma=\mathrm{9 . 4}\]

The shear stress on the sheet flow layer has to be transferred to the bed by sliding friction. It is assumed that this sliding friction is related to the internal friction angle, giving for the thickness of the sheet flow layer:

\[\ \begin{array}{left}\mathrm{H}=\frac{\tau_{12}}{\rho_{\mathrm{l}} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{C}_{\mathrm{v} \mathrm{s}, \mathrm{s} \mathrm{f}} \cdot \tan (\varphi)} \approx \frac{\mathrm{2} \cdot \mathrm{\theta} \cdot \mathrm{d}}{\mathrm{C}_{\mathrm{v} \mathrm{b}} \cdot \mathrm{t a n}(\varphi)}\\

\text{With: }\quad \mathrm{C}_{\mathrm{v s}, \mathrm{s} \mathrm{f}}= \mathrm{0.4} \cdot \mathrm{C}_{\mathrm{v b}}-\mathrm{0 .5} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}} \quad\text{ and }\quad \tan (\varphi)=\mathrm{0 .5 7 7}\end{array}\]

Assuming a linear concentration distribution in the sheet flow layer, starting at the bed concentration Cvb at the bottom of the sheet flow layer and ending with a concentration of zero at the top of the sheet flow layer gives:

\[\ \mathrm{C_{v s}(z)=C_{v b} \cdot\left(\frac{H-z}{H}\right)}\]

With z the vertical coordinate starting at the bottom of the sheet flow layer and increasing going upwards. The velocity in the sheet flow layer is assumed to start with the bed velocity at the bottom and ends with UH at the top following a power law according to:

\[\ \mathrm{U}(\mathrm{z})=\mathrm{U}_{\mathrm{H} 0} \cdot\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}}+\mathrm{v}_{\mathrm{2}}\]

The cross section of the sheet flow layer, reduced to the bed concentration Cvb is, assuming the average spatial sheet flow layer concentration is 50% of the bed concentration:

\[\ \Delta \mathrm{A}_{\mathrm{s f}}=\mathrm{H} \cdot \mathrm{O}_{12} \cdot \frac{\mathrm{C}_{\mathrm{v s}, \mathrm{s f}}}{\mathrm{C}_{\mathrm{v b}}} \approx \frac{\mathrm{H} \cdot \mathrm{O}_{12}}{\mathrm{2}}\]

The total amount of solids transported Qs is the amount transported in the remaining bed Q2 + the amount transported in the sheet flow layer Q12. The amount of solids transported in the bed is, corrected for the solids in the sheet flow layer:

\[\ \mathrm{Q}_{2}=\mathrm{v}_{2} \cdot\left(\mathrm{A}_{2}-\Delta \mathrm{A}_{\mathrm{s f}}\right) \cdot \mathrm{C}_{\mathrm{v b}}\]

The transport of solids in the sheet flow layer can now be determined by integration of the spatial concentration profile times the velocity profile in the sheet flow layer:

\[\ \mathrm{Q}_{12}=\mathrm{O}_{12} \cdot \int_{\mathrm{0}}^{\mathrm{H}} \mathrm{C}_{\mathrm{v s}}(\mathrm{z}) \cdot \mathrm{U}(\mathrm{z}) \cdot \mathrm{d z}=\mathrm{O}_{\mathrm{1 2}} \cdot \int_{\mathrm{0}}^{\mathrm{H}} \mathrm{C}_{\mathrm{v b}} \cdot\left(\frac{\mathrm{H}-\mathrm{z}}{\mathrm{H}}\right) \cdot\left(\mathrm{U}_{\mathrm{H} 0} \cdot\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}}+\mathrm{v}_{2}\right) \cdot \mathrm{d z}\]

\[\ \mathrm{Q}_{12}=\mathrm{O}_{\mathrm{1} 2} \cdot \mathrm{C}_{\mathrm{v b}} \cdot\left(\mathrm{v}_{\mathrm{2}} \cdot \int_{\mathrm{0}}^{\mathrm{H}}\left(\frac{\mathrm{H}-\mathrm{z}}{\mathrm{H}}\right) \cdot \mathrm{d z}+\mathrm{U}_{\mathrm{H} 0} \cdot \int_{\mathrm{0}}^{\mathrm{H}}\left(\frac{\mathrm{H}-\mathrm{z}}{\mathrm{H}}\right) \cdot\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}} \cdot \mathrm{d z}\right)\]

This can be rewritten to:

\[\ \mathrm{Q}_{12}=\mathrm{O}_{12} \cdot \mathrm{C}_{\mathrm{v b}} \cdot\left(\mathrm{v}_{2} \cdot \int_{\mathrm{0}}^{\mathrm{H}}\left(\mathrm{1}-\frac{\mathrm{z}}{\mathrm{H}}\right) \cdot \mathrm{d z}+\mathrm{U}_{\mathrm{H} 0} \cdot \int_{\mathrm{0}}^{\mathrm{H}}\left(\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}}-\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}+1}\right) \cdot \mathrm{d z}\right)\]

Integration gives:

\[\ \mathrm{Q}_{12}={\mathrm{O}}_{12} \cdot{\mathrm{C}}_{\mathrm{v b}} \cdot\left({\mathrm{v}}_{2} \cdot\left(\mathrm{z}-\frac{\mathrm{1}}{2} \cdot \mathrm{z}^{2}\right)+\mathrm{U}_{\mathrm{H} 0} \cdot \mathrm{H} \cdot\left(\frac{\mathrm{1}}{(\mathrm{n}+\mathrm{1})} \cdot\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}+1}-\frac{\mathrm{1}}{(\mathrm{n}+\mathrm{2})} \cdot\left(\frac{\mathrm{z}}{\mathrm{H}}\right)^{\mathrm{n}+2}\right)\right)_{0}^{\mathrm{H}}\]

With integration from zero to the thickness of the sheet flow layer this gives:

\[\ \mathrm{Q_{12}=H \cdot O_{12} \cdot C_{v b}} \cdot\left(\frac{\mathrm{v_{2}}}{2}+\frac{\mathrm{U_{H 0}}}{\mathrm{(n+1) \cdot(n+2)}}\right)\]

The total flow of solids equals the bed flow plus the sheet flow, which can be estimated by:

\[\ \mathrm{Q}_{\mathrm{s}}=\mathrm{Q}_{2}+\mathrm{Q}_{12}=\mathrm{v}_{2} \cdot\left(\mathrm{A}_{2}-\Delta \mathrm{A}_{\mathrm{s f}}\right) \cdot \mathrm{C}_{\mathrm{v b}}+\left(\mathrm{v}_{2}+\frac{\mathrm{2} \cdot \mathrm{U}_{\mathrm{H} 0}}{(\mathrm{n}+\mathrm{1}) \cdot(\mathrm{n}+\mathrm{2})}\right) \cdot \Delta \mathrm{A}_{\mathrm{s f}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}}\]

The delivered volumetric concentration equals the solids flow divided by the total flow:

\[\ \mathrm{C}_{\mathrm{v t}}=\frac{\mathrm{Q}_{\mathrm{s}}}{\mathrm{v}_{\mathrm{l} \mathrm{s}} \cdot \mathrm{A}_{\mathrm{p}}}\]

The above equations describe a relatively simple method to add sheet flow to the 2LM (2 layer model). This is possible because an explicit relation for the Darcy-Weisbach friction factor has been developed. Analyses of the above equations shows that the sheet flow concentration is not really important. Choosing a smaller sheet flow concentration results in a thicker sheet flow layer, but does not influence the velocity at the top of the sheet flow layer. A smaller sheet flow concentration does also not influence the reduced sheet flow cross-section and thus it does not influence the resulting delivered volumetric concentration.

Figure 7.4-28 to Figure 7.4-35 show a comparison between the 2LM and 3LM approach using the Miedema & Matousek (2014) method for the bed friction and the weight approach of Miedema & Ramsdell (2014) for the wall friction.

This model gives good predictions up to a certain line speed. First of all when the line speed is increasing, a part of the solids will be in suspension above the bed or above the sheet flow layer. This part of the solids is not taken into account in the model. This part will reduce the bed fraction, reduce the slip ratio and reduce the hydraulic gradient. Secondly, if the thickness of the sheet flow layer approaches the bed height, the whole bed will become sheet flow and the assumption of having sliding friction between the bed and the pipe wall will no longer be valid. This will also result in a strong decrease of the slip ratio and the hydraulic gradient. In fact there will no longer be a sliding bed and a heterogeneous model should be used.

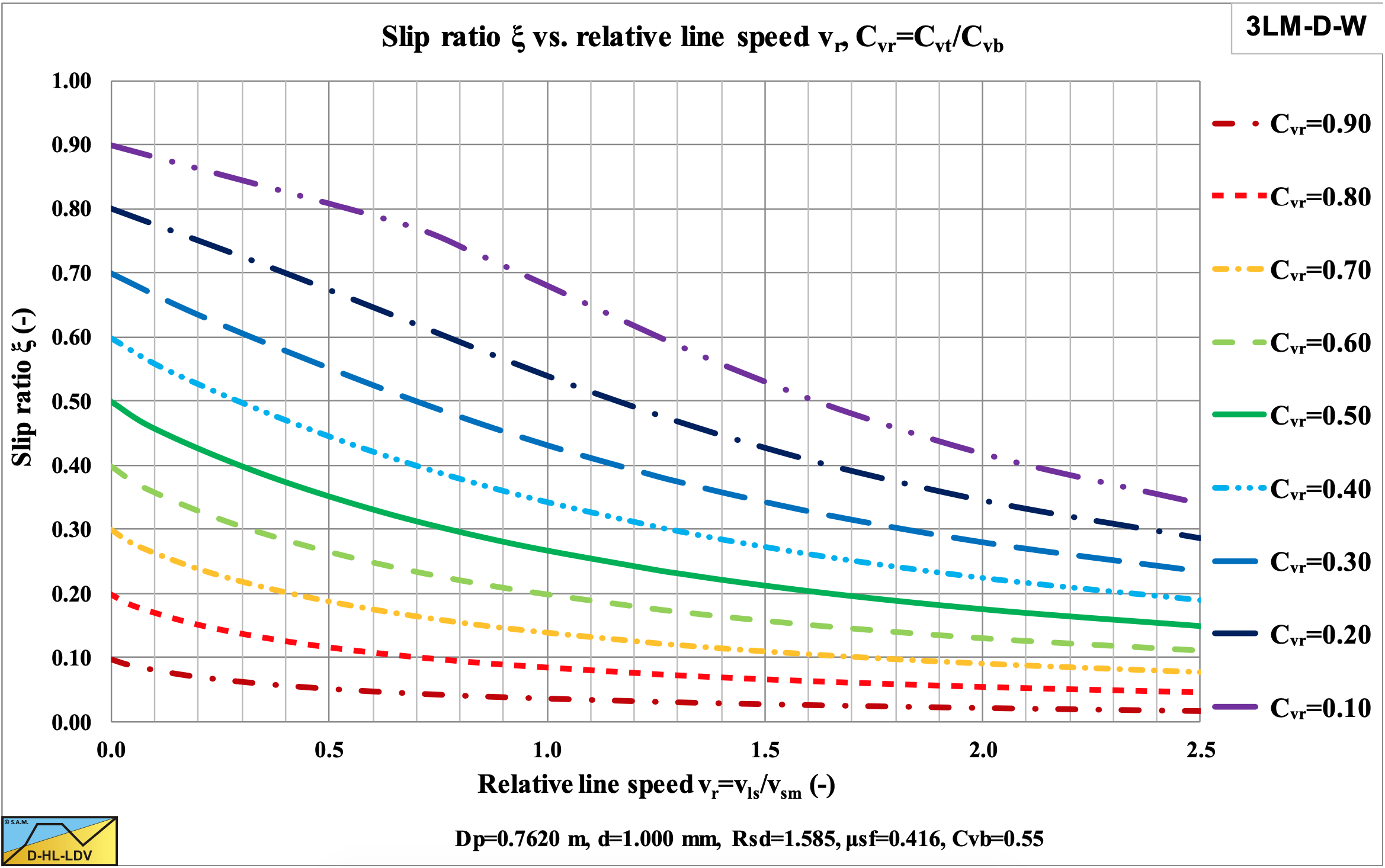

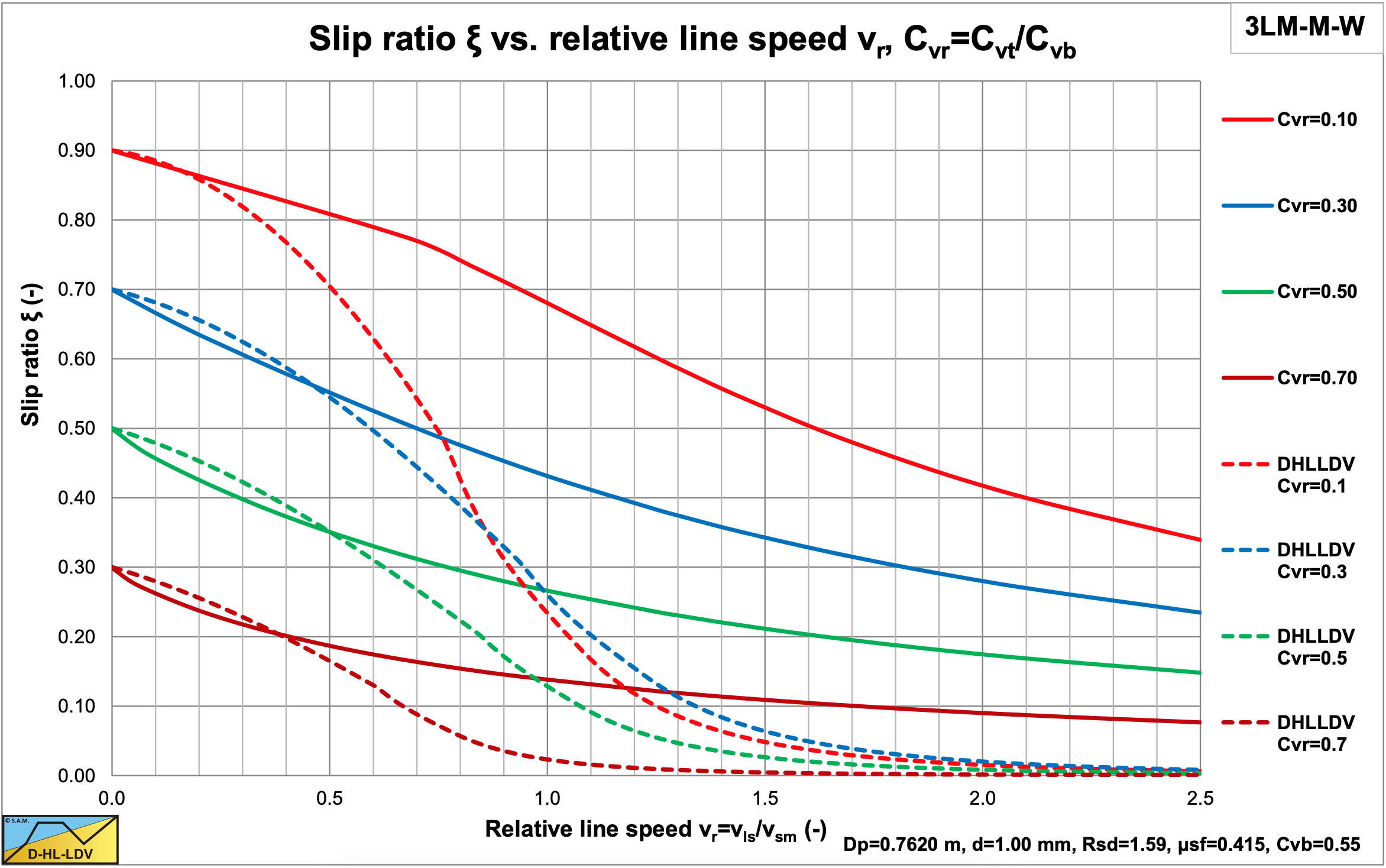

Figure 7.4-36 shows a comparison between the 3LM and the DHLLDV Framework regarding the slip ratio. At very low line speeds both models match close, but above a certain line speed, the DHLLDV Framework shows a strong reduction of the slip ratio, due to suspension and a dissolving bed. The conclusion is, that the 3LM model is suitable for very low line speeds, but not for line speeds close to the LDV, the line speed where the bed has been dissolved completely. Extending the 3LM with suspension above the sheet flow layer might improve the model.

The total flow of solids can be related to the Shields parameter, which is:

\[\ \theta=\frac{\tau_{12}}{\rho_{\mathrm{l}} \cdot \mathrm{R_{\mathrm{sd}}} \cdot \mathrm{g} \cdot \mathrm{d}}=\frac{\mathrm{u}_{*}^{2}}{\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{d}} \quad\text{ or }\quad \mathrm{u}_{*}=\sqrt{\theta \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot \mathrm{d}}\]

The velocity on top of the sheet flow layer can now be written as:

\[\ \begin{array}{left} \mathrm{U}_{\mathrm{H}}=\gamma \cdot \mathrm{u}_{*}+\mathrm{v}_{2}=\gamma \cdot \sqrt{\boldsymbol{\theta} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{d}}+\mathrm{v}_{\mathrm{2}}\\

\text{ With :} \quad \mathrm{U}_{\mathrm{H} \mathrm{0}}=\gamma \cdot \sqrt{\boldsymbol{\theta} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{d}}\end{array}\]

The total flow of solids equals the bed flow plus the sheet flow, which can be estimated by after substitution of the sheet flow layer cross section and the velocity on top of the sheet flow layer:

\[\ \mathrm{Q_{s}}=\mathrm{v_{2} \cdot\left(A_{2}-\frac{H \cdot O_{12}}{2}\right) \cdot C_{v b}+\left(v_{2}+\frac{2 \cdot \gamma \cdot \sqrt{\theta \cdot R_{s d} \cdot g \cdot d}}{(n+1) \cdot(n+2)}\right) \cdot \frac{H \cdot O_{12}}{2} \cdot C_{v b}}\]

Substituting the equation for the sheet flow layer thickness gives:

\[\ \begin{array}{left} \mathrm{Q_{s}=v_{2} \cdot\left(A_{2}-\frac{\theta \cdot d \cdot O_{12}}{C_{v b} \cdot \tan (\varphi)}\right) \cdot C_{v b}+\left(v_{2}+\frac{2 \cdot \gamma \cdot \sqrt{\theta \cdot R_{s d} \cdot g \cdot d}}{(n+1) \cdot(n+2)}\right) \cdot \frac{\theta \cdot d \cdot O_{12}}{C_{v b} \cdot \tan (\varphi)} \cdot C_{v b}}\\

\mathrm{Q_{s}=v_{2} \cdot A_{2} \cdot C_{v b}+\frac{2 \cdot \gamma \cdot \sqrt{\theta \cdot R_{s d} \cdot g \cdot d}}{(n+1) \cdot(n+2)} \cdot \frac{\theta \cdot d \cdot O_{12}}{C_{v b} \cdot \tan (\varphi)} \cdot C_{v b}}\\

\mathrm{Q_{s}=v_{2} \cdot A_{2} \cdot C_{v b}+\frac{2 \cdot \gamma}{(n+1) \cdot(n+2) \cdot \tan (\varphi)} \cdot d \cdot \sqrt{R_{s d} \cdot g \cdot d} \cdot O_{12} \cdot \theta^{3 / 2}}\end{array}\]

The first term on the right hand side shows the solids transport assuming that all solids in the pipe are transported in the bed with cross section A2 with a velocity v2. The second term on the right hand side shows the additional solids transport, because the velocity in the sheet flow layer is higher than the bed velocity. The latter is not the total solids transport in the sheet flow layer, just the additional solids transport compared with the case where there is no sheet flow layer. In the case of a stationary bed, v2=0, this gives:

\[\ \mathrm{Q_{s}=\frac{2 \cdot \gamma}{(n+1) \cdot(n+2) \cdot \tan (\varphi)} \cdot d \cdot \sqrt{R_{s d} \cdot g \cdot d} \cdot O_{12} \cdot \theta^{3/2}}\]

This can be written as a transport equation similar to the Meyer-Peter Muller (1948) (MPM) equation, giving the solods transport rate per unit of width of the bed in a dimensionless form:

\[\ \frac{\mathrm{Q}_{\mathrm{s}}}{\mathrm{d} \cdot \sqrt{\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot \mathrm{d}}{ \cdot \mathrm{O}_{\mathrm{1} 2}}}=\frac{\mathrm{2} \cdot \gamma}{(\mathrm{n}+\mathrm{1}) \cdot(\mathrm{n}+\mathrm{2}) \cdot \mathrm{\operatorname { tan } ( \varphi )}}{ \cdot \mathrm{\theta}^{3/2}=\mathrm{\alpha} \cdot \mathrm{\theta}^{\beta}}\]

The original MPM equation includes the critical Shields parameter, giving:

\[\ \frac{\mathrm{Q}_{\mathrm{s}}}{\mathrm{d} \cdot \sqrt{\mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{g} \cdot \mathrm{d}} \cdot \mathrm{O}_{\mathrm{1 2}}}=\mathrm{\alpha} \cdot\left(\mathrm{\theta}-\mathrm{\theta}_{\mathrm{c r}}\right)^{\beta} \quad\text{ with: }\quad \alpha=\mathrm{8} \quad\text{ and }\quad \beta=\mathrm{1 . 5}\]

For high values of the Shields parameter, both equations behave the same. With n=1 and tan(φ)=0.6, the theoretical equation gives α=5.22. With n=1 and tan(φ)=0.4, the theoretical equation gives α=8. With n=0.537 and tan(φ)=0.6, the theoretical equation also gives α=8. So both equations give results in the same range.

The sheet flow at the top of the bed does not influence the hydraulic gradient in the constant Cvs graphs, since in both the 2LM and the 3LM use the same equation is used for the bed shear stress. In the constant Cvt graphs however there is a difference because the transport concentration is influenced by the sheet flow. Also the slip and the bed fraction are influenced by the sheet flow.

The slip ratio of the 3 layer model is smaller than the slip factor of the 2 layer model, which is expected. This means that the 3 layer model results in less slip, which is to be expected.

The slip ratio from Figure 7.4-33 can be estimated by the following empirical equation:

| \[\ \begin{array}{left}\mathrm{C}_{\mathrm{v r}}=\frac{\mathrm{C}_{\mathrm{v t}}}{\mathrm{C}_{\mathrm{v} \mathrm{b}}} \quad\text{ and }\quad \alpha=\mathrm{0 . 5 8} \cdot \mathrm{C}_{\mathrm{v r}}^{-\mathrm{0} .42}\\ \frac{1}{1-\xi_{\mathrm{v}_{\mathrm{ls}, \mathrm{lsdv}}}}=\mathrm{C}_{\mathrm{vr}}^{-0.5}\\ \xi=\left(1-\mathrm{C}_{\mathrm{v r}}\right) \cdot \mathrm{e}^{\left(-\left(0.83+\frac{\mu_{\mathrm{sf}}}{4}+\left(\mathrm{c}_{\mathrm{vr}}-\mathrm{0 . 5 - 0 . 0 7 5 . \mathrm { D } _ { \mathrm { p } }}\right)^{2}+0.025 \cdot \mathrm{D}_{\mathrm{p}}\right) \cdot \mathrm{D}_{\mathrm{p}}^{0.025} \cdot\left(\frac{\mathrm{v}_{\mathrm{ls}}}{\mathrm{v}_{\mathrm{ls}, \mathrm{lsdv}}}\right)^{\alpha} \cdot \mathrm{C}_{\mathrm{vr}}^{0.65} \cdot\left(\frac{\mathrm{R}_{\mathrm{sd}}}{1.585}\right)^{0.1}\right)}\end{array}\] |

This equation has been developed based on the 3 layer approach, but is considered empirical. With additional simulations or modifications of the fundamental model, this equation may change in the future.

7.4.8 Nomenclature Sliding Bed Regime

|

Ap |

Cross section pipe |

m2 |

|

A1 |

Cross section above bed |

m2 |

|

A2 |

Cross section bed |

m2 |

|

Asf |

Cross section sheet flow layer |

m2 |

|

Cvb |

Volumetric bed concentration |

- |

|

Cvs |

Spatial volumetric concentration |

- |

|

Cvs,1 |

Spatial volumetric concentration upper layer |

- |

|

Cvs,2 |

Spatial volumetric concentration lower layer, bed |

- |

|

Cvs,sf |

Average spatial concentration in sheet flow layer |

- |

|

Cvt |

Delivered (transport) volumetric concentration |

- |

|

Cvr |

Relative volumetric concentration |

- |

|

d |

Particle diameter |

m |

|

Dp |

Pipe diameter |

m |

|

Erhg |

Relative excess hydraulic gradient |

- |

|

Fn |

Normal force |

kN |

|

Ft |

Tangent force |

kN |

|

Fw |

Weight of bed |

kN |

|

Fsf |

Sliding friction force |

kN |

|

Fh |

Horizontal force |

kN |

|

Fh,n |

Component horizontal force normal to pipe wall |

kN |

|

Fh,t |

Component horizontal force tangent to pipe wall |

kN |

|

Fv |

Vertical force |

kN |

|

Fv,n |

Component vertical force normal to pipe wall |

kN |

|

Fv,t |

Component vertical force tangent to pipe wall |

kN |

|

hb |

Bed height above point on the pipe wall |

m |

|

H |

Thickness sheet flow layer |

m |

|

g |

Gravitational constant 9.81 m/s2 |

m/s2 |

|

il |

Hydraulic gradient pure liquid |

m/m |

|

im |

Hydraulic gradient mixture |

m/m |

|

iplug |

Hydraulic gradient plug flow |

m/m |

|

K |

Failure factor, ratio horizontal stress to vertical stress |

- |

|

Ka |

Factor of active failure |

- |

|

Kp |

Factor of passive failure |

- |

|

ΔL |

Length of pipe section |

m |

|

n |

Power of velocity distribution in sheet flow layer |

- |

|

Op |

Circumference pipe |

m |

|

O1 |

Circumference pipe above bed |

m |

|

O2 |

Circumference pipe in bed |

m |

|

O12 |

Width of bed |

m |

|

Δpl |

Head loss pure liquid |

kPa |

|

Δpm |

Head loss mixture |

kPa |

|

Qs |

Total amount of solids transported by volume |

m3/s |

|

Q2 |

Amount of solids transported in the bed |

m3/s |

|

Q12 |

Amount of solids transported in the sheet flow layer |

m3/s |

|

Rsd |

Relative submerged density |

- |

|

R |

Pipe radius |

m |

|

u* |

Friction velocity |

m/s |

|

UH |

Velocity at the top of the sheet flow layer |

m/s |

|

UH0 |

Velocity at the top of the sheet flow layer with fixed bed |

m/s |

|

vls |

Line speed |

m/s |

|

vr |

Relative line speed |

- |

|

vsm |

Maximum Limit of Stationary Deposit Velocity |

m/s |

|

v1 |

Velocity above bed |

m/s |

|

v1,m |

Mean velocity above bed, upper layer |

m/s |

|

v2 |

Velocity bed |

m/s |

|

v2,m |

Mean velocity bed, lower layer |

m/s |

|

yb |

Height of bed |

m |

|

z |

Vertical coordinate in sheet flow layer |

m |

|

α |

Angle of position in bed |

rad |

|

α |

Factor MPM equation |

- |

|

β |

Bed angle |

rad |

|

β |

Power MPM equation |

- |

|

φ |

Angle of internal friction |

rad |

|

\(\ \gamma\) |

Wilson factor velocity at top of sheet flow layer |

- |

|

ρl |

Density carrier liquid |

ton/m3 |

|

θ |

Shields parameter |

- |

|

θc |

Critical Shields parameter |

- |

|

λ12 |

Darcy-Weisbach friction factor on the bed |

- |

| \(\ \tau_{12}\) |

Shear stress bed-liquid |

kPa |

| \(\ \tau_{\mathrm{sf}}\) |

Shear stress due to sliding friction |

kPa |

| \(\ \tau_{\mathrm{t}}\) |

Shear stress in bed tangent to pipe wall |

kPa |

|

μsf |

Sliding friction coefficient |

- |

|

μsf,e |

Effective or mobilized sliding friction coefficient |

- |

|

σn |

Normal stress |

kPa |

|

σh |

Horizontal stress |

kPa |

|

σv |

Vertical stress |

kPa |

|

ζ |

Bed fraction |

- |

|

ξ |

Slip ratio |

- |