6.3: Types of Lighting

- Page ID

- 47186

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)There are four basic types of lighting:

- Incandescent

- Fluorescent

- High-intensity discharge

- Low-pressure sodium

Incandescent Bulbs

Thomas Alva Edison invented the incandescent light bulb with reasonable life. Lewis Latimer has perfected it with the use of carbon filament.

The incandescent bulb consists of a sealed glass bulb with a filament inside. When electricity is passed through the filament, the filament gets hot. Depending on the temperature of the filament, radiation is emitted from the filament.

The filament's temperature is very high, generally over 2,000º C, or 3,600º F. In a "standard" 60-, 75-, or 100-Watt bulb, the filament temperature is roughly 2,550º C, or roughly 4,600º F. At high temperatures like this, the thermal radiation from the filament includes a significant amount of visible light.

This principle of obtaining light from heat is called ‘incandescence.” At this high temperature of 2,000º C, about 5 percent of the electrical energy converts into visible light and the rest of it is emitted as heat or infrared radiation.

The following video shows how an incandescent light bulb works.

Let’s now look at several different types of incandescent bulbs.

Standard Incandescent Bulbs

Standard incandescent bulbs are most common and yet are the most inefficient. Larger wattage bulbs have a higher efficacy (more lumens per Watt) than smaller wattage bulbs.

Tungsten Halogen Bulbs

Tungsten halogen is an incandescent lamp with gases from the halogen family sealed inside the bulb and an inner coating that reflects heat back to the filament, as shown in Figure 6.3.1. It has similar light output to a regular incandescent bulb, but with less power. Halogens in the gas filling reduce the material losses of the filament caused by evaporation and increase the performance of the lamp.

Figure 6.3.1. A tungsten halogen lamp

Tubular Tungsten-Halogen Bulbs

Tubular tungsten-halogen bulbs are commonly used in “torchiere” floor lamps, as shown in Figure 6.3.2, which reflect light off of the ceiling, providing more diffused and suitable general lighting.

Although these provide better energy efficiency than the standard A-type bulb, these lamps consume significant amounts of energy (typically drawing 300 to 600 W) and become very hot (a 300-W tubular tungsten-halogen bulb reaches a temperature of about 2600° C compared to about 600° C for a compact fluorescent bulb). Because Tungsten-halogen lamps operate at very high temperatures (high enough to literally fry eggs), they should not be used in fixtures that have paper- or cellulose-lined sockets.

Figure 6.3.2. Tubular tungsten halogen lamp

Halogen Bulb

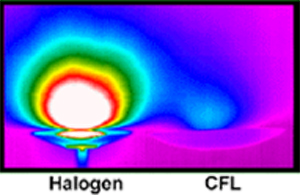

A halogen bulb is often 10 to 20 percent more efficient than an ordinary incandescent bulb of similar voltage, wattage, and life expectancy. Halogen bulbs may also have two to three times as long a lifetime as ordinary bulbs. How much the lifetime and efficiency are improved depends largely on whether a premium fill gas (usually krypton, sometimes xenon) or argon is used. Figure 6.3.3 shows a picture taken with an Infrared camera comparing the heat produced by a halogen and a compact fluorescent light bulb. The red and white color zones are extremely hot and the blue zones are cooler.

Figure 6.3.3. A comparison of heat generated by a halogen and CFL light bulbs

Reflector Lamps

Reflector Lamps - Light waves from a bulb spread in all directions. The light that goes toward the back is not useful when the light is most needed in the front. Reflector lamps (Type R) are designed to spread light over specific areas.

Reflector lamps have silver coating on the sides, like any mirror, and therefore all the light waves passing through the sides or the back are reflected to the front. Therefore, they are called reflector lamps and are also called floodlighting, spotlighting, and down lighting bulbs.

The videos below show the difference between a regular and reflective lamp light bulb.

Parabolic Aluminized Reflector (PAR) Lamps

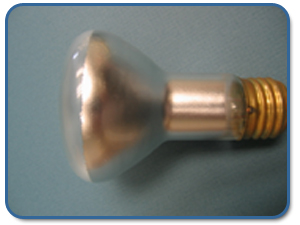

Parabolic aluminized reflector (PAR) lamps (shown in Figure 6.3.4) are also available with halogen technology to operate at 120 volts. A standard 150-W incandescent spotlight can be replaced with a lower wattage halogen lamp, reducing electricity consumption by up to 40 percent.

Figure 6.3.4. A reflector lamp (type R) light bulb

Fluorescent Bulbs

The fluorescent lamp is a major advancement and a commercial success in small-scale lighting since the original tungsten incandescent bulb. These bulbs are highly efficient compared to incandescent bulbs. Fluorescence is the phenomenon in which absorption of light of a given wavelength by a fluorescent molecule is followed by the emission of light at longer wavelengths. The following video provides more information on fluorescent bulbs.

A fluorescent bulb consists of a glass tube with a phosphorus coating, a small amount of inert gas (usually argon or krypton), mercury, and a set of electrodes. Contact points on the outside of the tube carry electricity into the bulb.

The video below shows a step-by-step depiction of how fluorescent lamps provide light.

Fluorescent lamps are about 2 to 4 times as efficient as incandescent lamps at producing light at the wavelengths that are useful to humans. Thus, they run cooler for the same effective light output. The bulbs themselves also last a lot longer—10,000 to 20,000 hours versus 1,000 hours for a typical incandescent.

Fluorescent lights need ballasts (devices that control the electricity used by the unit) for starting and for circuit protection. Ballasts require energy, and for some type of ballasts, efficiency is only achieved if the fluorescent lamp is left on for long periods of time without frequent on-off cycles.

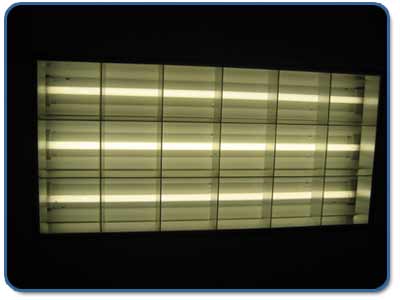

Figure 6.3.5. shows a picture of a full-size fluorescent lamp fixture. The energy savings for existing fluorescent lighting can be increased by:

- re-lamping (e.g., replacing an existing lamp with one of a lower wattage);

- replacing ballasts;

- replacing fixtures with more efficient models.

Figure 6.3.5. Full-size fluorescent lamp fixture

Full-size fluorescent lamps are available in several shapes, including straight, U-shaped, and circular configurations. Lamp diameters range from 1" to 2.5". The most common lamp type is the four-foot (F40), 1.5" diameter (also called T12) straight fluorescent lamp. More efficient fluorescent lamps are now available in smaller diameters, including the 1.25 " (also called T10) and 1" (also called T8).

Fluorescent lamps are available in color temperatures ranging from warm (2700 K) "incandescent-like" colors to very cool (6500 K) "daylight" colors.

Cool white (4100 K) is the most common fluorescent lamp color. Neutral white (3500 K) is becoming popular for office and retail use.

Compact Fluorescent Lamps

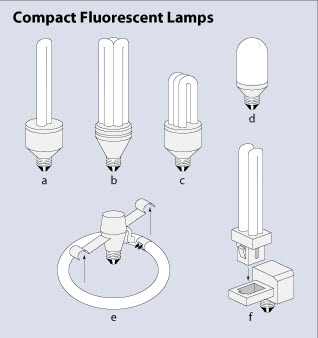

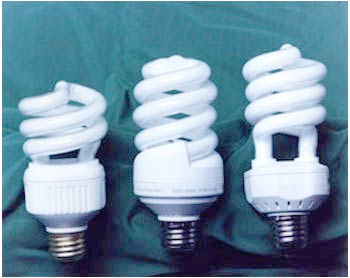

Compact fluorescent lamps (CFLs) are miniaturized fluorescent lamps that usually have premium phosphors which often come packaged with integral or modular ballast, as shown in Figure 6.3.6.

Figure 6.3.6. Types of compact fluorescent bulbs on the market

CFLs come in a variety of sizes and shapes, as shown in Figure 6.3.7, including (a) twin-tube integral, (b and c) triple-tube integral, (d) integral model with casing that reduces glare, (e) modular circline and ballast, and (f) modular quad-tube and ballast. CFLs can be installed in regular incandescent fixtures, and they consume less than one-third as much electricity as incandescent lamps.

CFLs have the following characteristics. They:

- Typically have a standard screw base that can be installed into nearly any table lamp or lighting fixture that accepts an incandescent lamp.

- Come in a variety of sizes and shapes and are being used as energy saving alternatives to incandescent lamps.

- Have a much longer life—6,000 to 20,000 hours (10 to 20 times longer), compared to 750 to 1000 hours for a standard incandescent.

- Can replace incandescent bulbs that are roughly 3 to 4 times their wattage, but can cost up to 10 times more than comparable incandescent bulbs.

- Are one of the best energy-efficiency investments available. Although they cost more, they are very economical in the long run.

Figure 6.3.7. CFLs

High-Intensity Discharge

High-intensity discharge (HID) lamps are similar to fluorescents in that an arc is generated between two electrodes. The arc in an HID source is shorter, yet it generates much more light, heat, and pressure within the arc tube.

Below are HID sources, listed in increasing order of efficacy (lumens per watt):

- mercury vapor

- metal halide

- high-pressure sodium

- low-pressure sodium

Like fluorescent lights, HID also requires ballasts, and they take a few seconds to produce light when first turned on because the ballast needs time to establish the electric arc.

Additional Information

Originally developed for outdoor and industrial applications, HID lamps are now used in office, retail, and other indoor applications. Their color rendering characteristics have been improved, and lower wattages have recently become available (as low as 18 watts).

Table 6.3.1 analyzes the details of HID lamps.

Table 6.3.1. Advantages and disadvantages of HID lamps

| Advantages | Disadvantages |

|---|---|

|

|

Additional Information

When HID lamps reach "restrike" time, the gasses inside the lamp are too hot to ionize, and time is needed for the gasses to cool and pressure to drop before the arc will restrike. This process of restriking takes between 5 and 15 minutes, depending on which HID source is being used. Therefore, good applications of HID lamps are areas where lamps are not switched on and off intermittently.

Types of HID Lamps

Mercury Vapor Lamps

Mercury vapor lamps, shown in Figure 6.3.8, are widely used to light both indoor and outdoor areas such as gymnasiums, factories, department stores, banks, highways, parks, and sports fields.

Mercury vapor lamps consist of an inner arc discharge tube constructed of quartz surrounded by an outer hard borosilicate glass envelope. Shortwave UV, a result of the decay of mercury atom electrons from an excited to a stable state, is readily transmitted through the inner quartz tube but is virtually blocked by the outer glass envelope during normal operation.

Figure 6.3.8. Mercury vapor lamp

Metal Halide Lamps

Metal Halide lamps are similar to mercury vapor lamps but use metal halide additives inside the arc tube along with the mercury and argon. These additives enable the lamp to produce more visible light per watt with improved color rendition.

Wattages range from 32 to 2,000, offering a wide range of indoor and outdoor applications. The efficacy of metal halide lamps ranges from 50 to 115 lumens per watt, typically about double that of mercury vapor.

Because of the good color rendition and high lumen output, these lamps are good for sports arenas and stadiums. Indoor uses include large auditoriums and convention halls. These lamps are sometimes used for general outdoor lighting, such as parking facilities, but a high-pressure sodium system is typically a better choice.

Table 6.3.2 analyzes metal halide lamps.

Table 6.3.2. Advantages and disadvantages of metal halide lamps

| Advantages | Disadvantages |

|---|---|

|

|

High-Pressure Sodium (HPS) Lamps

The high-pressure sodium (HPS) lamp is widely used for outdoor and industrial applications. Its higher efficacy makes it a better choice than metal halide for these applications, especially when good color rendering is not a priority.

HPS lamps differ from mercury and metal-halide lamps in that they do not contain starting electrodes; the ballast circuit includes a high-voltage electronic starter. The arc tube is made of a ceramic material which can withstand temperatures up to 2,372°F. It is filled with xenon to help start the arc, as well as a sodium-mercury gas mixture.

The efficacy of the HPS lamp is very high (as much as 140 lumens per watt.) For example, a 400-watt high pressure sodium lamp produces 50,000 initial lumens. The same wattage metal halide lamp produces 40,000 initial lumens, and the 400-watt mercury vapor lamp produces only 21,000 initially.

Sodium, the major element used, produces the "golden" color that is characteristic of HPS lamps. Although HPS lamps are not generally recommended for applications where color rendering is critical, HPS color rendering properties are being improved. Some HPS lamps are now available in "deluxe" and "white" colors that provide higher color temperature and improved color rendition. The efficacy of low-wattage "white" HPS lamps is lower than that of metal halide lamps (lumens per watt of low-wattage metal halide is 75-85, while white HPS is 50-60 LPW).

Low-Pressure Sodium Lamps

Low-pressure sodium lamps—producing up to 180 lumens per watt—have the highest efficacy of all commercially available lighting sources. A low-pressure sodium lamp is shown in Figure 6.3.9.

Even though they emit a yellow light, a low-pressure sodium lamp should NOT be confused with a standard high-pressure sodium lamp, which is a high-intensity discharge lamp.

Figure 6.3.9. Low-pressure sodium lamp

Low-pressure sodium lamps operate much like fluorescent lamps and require ballast. The lamps are also physically large—about 4-feet long for the 180-watt size—so light distribution from fixtures is less controllable. There is a brief warm-up period for the lamp to reach full brightness.

With a CRI of 0, low-pressure sodium lamps are used where color rendition is not important but energy efficiency is. They're commonly used for outdoor, roadway, parking lot, and pathway lighting. Low-pressure sodium lamps are preferred around astronomical observatories because the yellow light can be filtered out of the random light surrounding the telescope.