14.1: Introduction

- Page ID

- 31017

Logistics has to do with the procurement, storage, transportation, and delivery of goods or people. A logistics system deals with the way finished products move from producer to customer or raw material moves from a supplier to the producer. Logistics systems must be responsive to customer requirements for short lead times. That is the amount of time between the placement of an order and its delivery should be minimized. Using excessive amounts of inventory or capital equipment to accomplish this objective increases costs and thus is inconsistent with lean principals.

Movement of goods may involve truck, rail, water, and air transportation. Facilities for loading and receiving products by each mode of transporation employed are necessary. Evaluating trade-offs between using various transporation modes can be a part of a simulation study.

Inspection and repair of transportation equipment is important. Inspection is often required after each round trip to a customer and returning to the shipping site. Inspection delays and subsequent repair times if necessary must be included in a simulation model.

Determining how many trucks, rail cars, or aircraft are needed must be accomplished. This is known as fleet sizing. Fleet size estimates are often made using simple algebra based on the expected round trip time to a customer, including inspection and repair as well as the number of round trips needed per planning period. This result is the lower bound on the fleet size. Simulation allows the effects of variability on meeting customer requirements for timely deliveries to be considered when sizing a fleet so that a more precise esitimate is obtained. Variability sources include transportation times and customer demands.

Staffing plans for logistics systems are necessary. A lack of staff may prove to be a constraint on the number of loads shipped. Staff may work only certain shifts during the day and only certain days of the week. Such scheduling may result in structural variability that causes the need for additional inventory or capital equipment.

Logistics systems add no value to products. Thus, their cost needs to be minimized. On the other hand, they are critical to making sure customers are satisfied by receiving products on time.

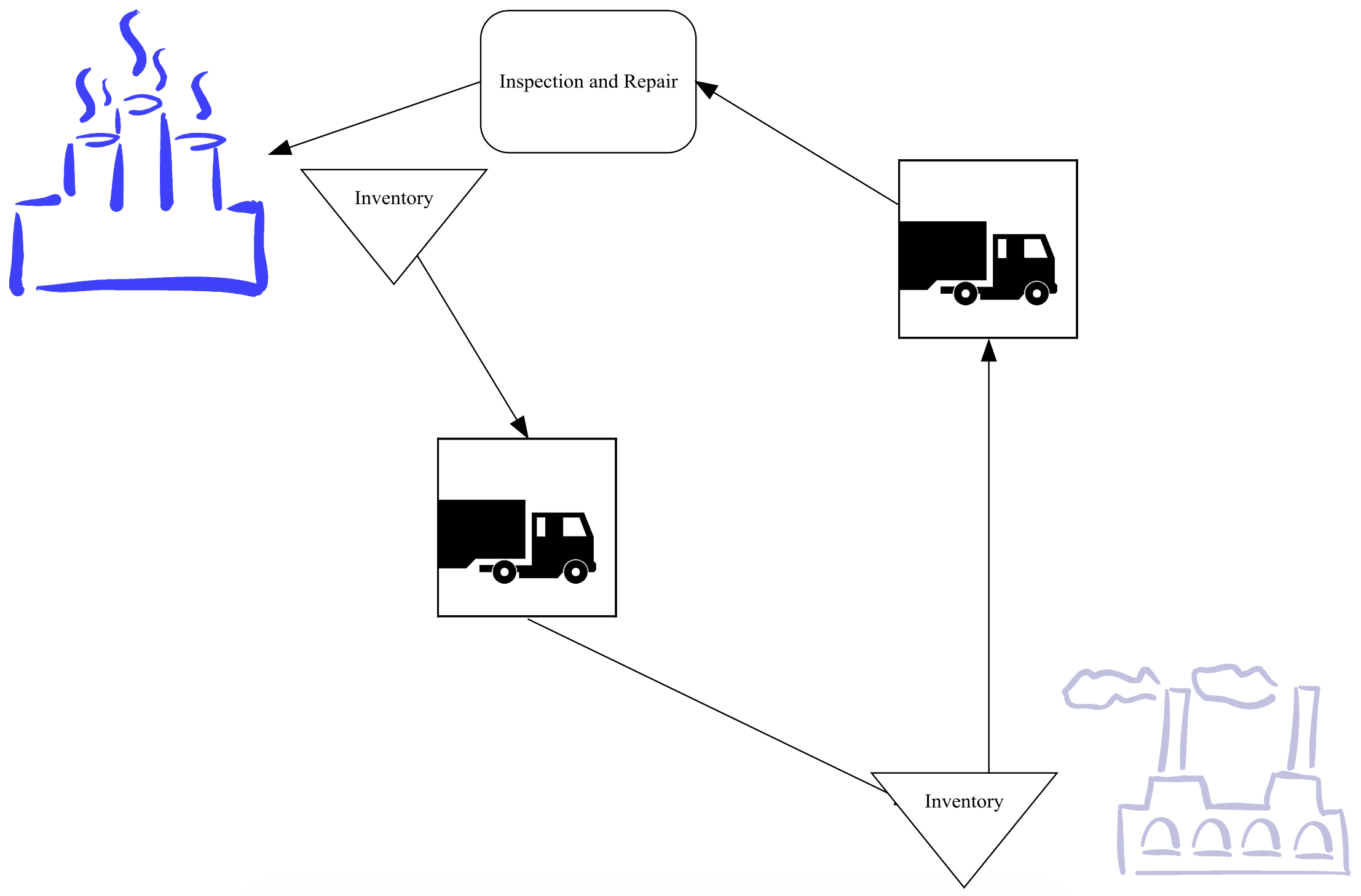

A simple logistic system is shown in Figure 14-1. A factory creates product which is stored in an inventory. Customer demands result in shipments via truck to the customer site. After the shipment is unloaded into the customer's inventory, the truck returns to the factory for inspection and repair as well as to await its next shipment.

This chapter discusses a basic and straightforward logistic system with an emphasis on fleet sizing. A more complex logistic system as required in a supply chain is discussed in the next chapter.

Figure 14-1: Simple Logistics System