16.1: Introduction

- Page ID

- 31025

Companies such as FedEx and United Parcel Service specialize in the delivery of packages often when time is critical. The network of trucks and airplanes employed by such a company transports millions of packages to both business and personal customers each year.

The ground based shipping methods employed by these companies typically rely on a network of terminals and hubs to move packages throughout the country. Vans are used to pick up packages from customers and deliver them to a small terminal. If a package needs to be sent outside of the terminal's delivery area, it is loaded onto a tractor-trailer truck and sent to a hub.

Most hubs are located in major cities with hundreds of the smaller terminals located in smaller cities. Tractor-trailers containing packages to be shipped a great distance across the country can be loaded onto railcars to reduce cost. When the tractor-trailer arrives at a hub, the packages it contains are sorted by destination. Outbound packages can be loaded into vans for local delivery or sent to other hubs throughout the network.

At the heart of the hub is the material handling system usually a conveyor system. The conveyor system is used to unload, sort and transport packages throughout the hub. Hub facilities may be of enormous size, some containing 8 miles of conveyor. The hub material handling system is built up in phases. Each phase typically adds a copy of the original system as well as expanding it. Phased development reduces the financial risk associated with installing the complete system before the demand to support it exists.

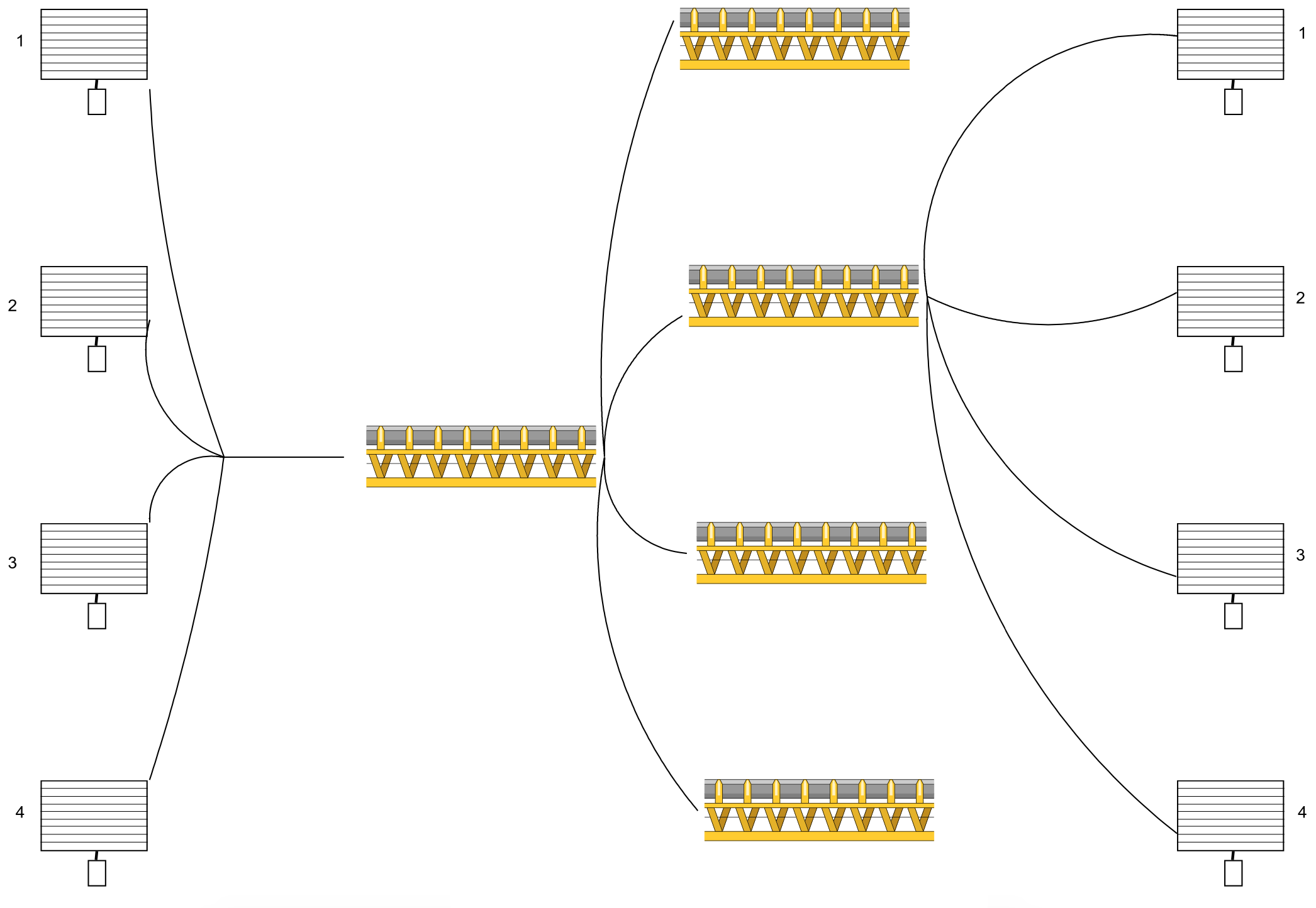

The material handling structure employed by a typical hub is shown in Figure 16-1. A truck arrives to one of many docks that comprise the unload area. A large conveyor is extended into the truck. A worker manually unloads each truck and places the packages it contains on the conveyor.

A set of conveyors, usually four in number, used in truck unloading is called a bank. Typically, each pair of unload banks feeds a primary sorter, which processes packages from multiple unloading doors at once. A variety of logic is used to merge packages on to a single conveyor before reaching the primary sorter.

Each of the primary sorters routes packages to one of many secondary sorters. A secondary sorter routes each package to a particular lane and hence to an outbound truck. A worker removes each package from a lane and places it in the proper truck. A lane corresponds to a particular zip code or truck destination. A typical secondary sorter supports 20 lanes.

Figure 16-1: Typical Package Transfer Hub Layout