11.2: Summary

- Page ID

- 95321

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\dsum}{\displaystyle\sum\limits} \)

\( \newcommand{\dint}{\displaystyle\int\limits} \)

\( \newcommand{\dlim}{\displaystyle\lim\limits} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\(\newcommand{\longvect}{\overrightarrow}\)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)11.2.7 Summary

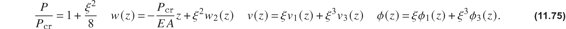

From this initial post-buckling analysis the results for the expansions of the load, displacements, and rotation are

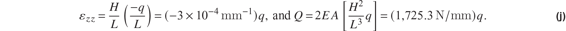

The strain of the centroidal axis is

Rotation functions ϕ1(z) and ϕ3(z) are given by eqs. (11.38) and (11.69), respectively. Lateral displacement functions v1(z) and v3(z) are given by eqs. (11.39) and (11.70), respectively, and the axial displacement function w2(z) is given by eq. (11.74).

Example 11.2 Numerical results for the initial post-buckling of the pinned-pinned column

Consider the column with a solid, rectangular cross section of height h and width b, where h < b. The radius of gyration is  . The strain at the bifurcation point is obtained from eq. (11.76) for ξ→0 is

. The strain at the bifurcation point is obtained from eq. (11.76) for ξ→0 is  , and take this strain equal to

, and take this strain equal to  . Since

. Since  , we have

, we have

Hence, the span-to-thickness ratio  .

.

The restriction on the magnitude of the expansion parameter ξ in the initial post-buckling analysis is based on the strain at the elastic limit of 7075-T6 aluminum alloy, which is about 0.0068. Let  denote the strain of a line element parallel to the centroidal axis. It is the sum of the strain of centroidal axis εzz plus the strain due to bending. That is,

denote the strain of a line element parallel to the centroidal axis. It is the sum of the strain of centroidal axis εzz plus the strain due to bending. That is,

where  and dϕ∕dz is the curvature of the centroidal axis. The magnitude of the maximum compressive strain in post-buckling occurs at midspan,

and dϕ∕dz is the curvature of the centroidal axis. The magnitude of the maximum compressive strain in post-buckling occurs at midspan,  , and

, and  . That is,

. That is,

The expansion for the curvature at midspan is determined from eqs. (11.75), (11.38) and (11.69). The result is

Substitute  and

and  in the expansions for the strains. The numerical evaluations of the strain in eq. (11.76) and the strain from bending are

in the expansions for the strains. The numerical evaluations of the strain in eq. (11.76) and the strain from bending are

The axial strain on the concave side of the bar at midspan is set equal to the elastic limit strain of  . Thus,

. Thus,

The real root of the previous polynomial is the maximum value of parameter ξ, which is

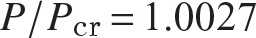

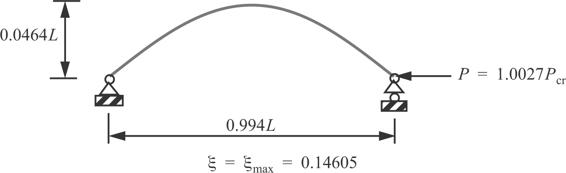

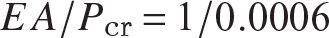

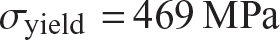

For post-buckling coefficients a = 0 and  , we get

, we get  at

at  from eq. (11.54). There is a very small increase in the load during post-buckling. The lateral displacement of the column is determined from eqs. (11.75), (11.39), and (11.70), and it is a maximum at midspan. Evaluation of the maximum displacement is

from eq. (11.54). There is a very small increase in the load during post-buckling. The lateral displacement of the column is determined from eqs. (11.75), (11.39), and (11.70), and it is a maximum at midspan. Evaluation of the maximum displacement is

and  at

at  .

.

The axial displacement of the column is determined from eqs. (11.75) and (11.74). The shortening of distance between supports is

The shortening at buckling is  , and the normalized shortening is defined by

, and the normalized shortening is defined by

At  ,

,  on the post-buckling path. The configuration of the column at ξmax is shown in figure 11.8.

on the post-buckling path. The configuration of the column at ξmax is shown in figure 11.8.

Fig. 11.8 Post-buckling configuration of the pinned-pinned column at the elastic limit strain.

The pre-buckling equilibrium path is determined from eq. (11.14) where  , or

, or  . Divide by the critical load to get

. Divide by the critical load to get  . From eq. (a) the factor

. From eq. (a) the factor  . Thus,

. Thus,  on the pre-buckling equilibrium path.

on the pre-buckling equilibrium path.

Fig. 11.9 Equilibrium paths for the pinned-pinned column subject to axial compression (a) on the load-deflection plot, and (b) on the load-shortening plot.

The load-deflection response is shown in figure 11.9(a), and the load-shortening response is shown in figure 11.9(b). The post-buckling behavior of the column is stable symmetric bifurcation, which is the same behavior as model A in article 10.1 on page 265. The load does not decrease in post-buckling. However, the increase in load is very small in post-buckling. From a practical point of view, the column is considered neutral in post-buckling.The structural stiffness is defined as dP∕dΔ. For post-buckling the structural stiffness is computed as

The structural stiffness in pre-buckling is (EA)∕L. The ratio of the post-buckling stiffness to the pre-buckling stiffness is 0.0003, which indicates the dramatic loss of structural stiffness due to buckling.

■

From eq. (11.54) the perturbation expansion of the load in initial post-buckling is  . The post-buckling coefficients a = 0 and b < 0 correspond to unstable symmetric bifurcation behavior illustrated by model B in article 10.2 on page 273. Post-buckling coefficient a ≠ 0 corresponds to asymmetric bifurcation behavior illustrated by model C in article 10.3 on page 277.

. The post-buckling coefficients a = 0 and b < 0 correspond to unstable symmetric bifurcation behavior illustrated by model B in article 10.2 on page 273. Post-buckling coefficient a ≠ 0 corresponds to asymmetric bifurcation behavior illustrated by model C in article 10.3 on page 277.

11.3 In-plane buckling of trusses

When a truss has all of its joints pinned, then there will be no interaction between the bending deflections of individual members. Hence the buckling load of the truss will be the load at which the weakest compression member buckles as an Euler column (case A in figure 11.6). However, when a truss is rigidly jointed, as in a frame, there will be interaction between bending deflections of neighboring members through rotation of the common joint. A rigid-jointed truss is stiffer than a pin-jointed truss, and therefore its buckling load is increased relative to the pin-jointed truss.

Example 11.3 Buckling of a two-bar truss

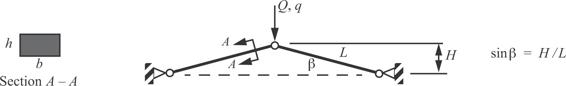

A symmetric truss consisting of two identical bars of length L are connected together by a hinge joint at the center of the truss. The opposite end of each bar connects to a separate hinge joint at a fixed support. Both supports are at a distance H below central joint. The central joint is subject to downward load Q whose corresponding displacement is denoted by q.

We consider a linear analysis and a nonlinear analysis for the stability of the truss, where Hooke’s law governs the material behavior in both analyses. The material of the bars is 7075-T6 aluminum alloy with a modulus of elasticity  and yield strength of

and yield strength of  . The remaining numerical data are listed in table 11.2. From the data in table 11.2 the angle

. The remaining numerical data are listed in table 11.2. From the data in table 11.2 the angle  . A small value of β characterizes a shallow truss configuration.

. A small value of β characterizes a shallow truss configuration.

Fig. 11.10 A shallow truss horizontally constrained between fixed points.

Table 11.2 Numerical data for the truss in figure 11.10

|

Length of truss bars L, mm |

300 |

Width of truss bar b, mm |

25 |

|

Truss rise above supports H, mm |

27 |

Area of truss bar A, mm2 |

450 |

|

Thickness of truss bar h, mm |

18 |

Second area moment I, mm4 |

12,150 |

Axial strain-displacement relation. The strain-displacement relation (11.7) for each bar is

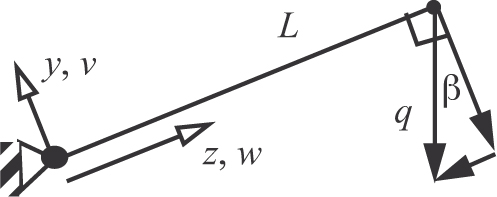

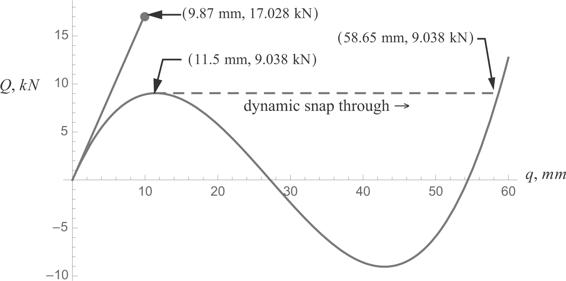

Fig. 11.11 Left-hand bar of the truss.

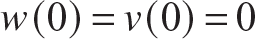

where the axial displacement is denoted by w(z) and the lateral displacement is denoted by v(z). Consider the bar on the left-hand side of the truss as shown in figure 11.11. At the fixed end where z = 0,  . At the end of the bar where z = L the axial displacement and the lateral displacement are related to the downward displacement q of the movable joint by

. At the end of the bar where z = L the axial displacement and the lateral displacement are related to the downward displacement q of the movable joint by  and

and  , respectively. The axial strain in a truss bar is uniform along its length, which means that the displacements are linear in coordinate z. Linear displacement functions for each displacement satisfying the end conditions are,

, respectively. The axial strain in a truss bar is uniform along its length, which means that the displacements are linear in coordinate z. Linear displacement functions for each displacement satisfying the end conditions are,

Substitute eq. (b) for the displacement functions into eq. (a) to get the strain-displacement relation

Substitute  , and

, and  into eq. (c) to get

into eq. (c) to get

Numerical evaluation of eq. (d) is

The strain energy of the truss is

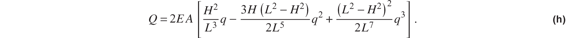

in which the leading factor of 2 accounts for the two bars. Castigliano’s first theorem determines the force Q by

Substitute eq. (d) for the strain into eq. (f) to get

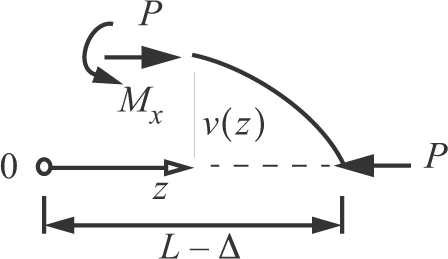

Numerical evaluation of eq. (h) is

In-plane buckling of the truss bars based on linear analysis. The expressions for the axial strain (e) and applied load (h) reduce to

The axial force in each bar is given by

The Euler buckling force  . Set

. Set  to find the displacement for in-plane buckling of the truss bars

to find the displacement for in-plane buckling of the truss bars  . The corresponding load

. The corresponding load  .

.

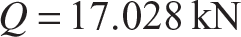

Equations (i) and (j) are plotted on the graph of load Q versus displacement q in figure 11.12. As the load is increased from zero on the nonlinear path (i) a limit point load of 9.038 kN at a displacement of 11.5 mm is encountered. As discussed in article 10.5 a dynamic snap-through motion occurs at the limit load that eventually (with damping) settles to a displacement of 58.65 mm. The linear response path (j) is the straight line in figure 11.12, and the load causing in-plane buckling of the truss bars is 17.028 kN. Thus, the critical load for this structure is at the limit point.

■

11.4 Geometrically imperfect column

Consider a uniform, pinned-pinned column that is slightly crooked under no load. The initial shape under no load is described by the function v0(z). The column is subject to a centric, axial compressive load P. The lateral displacement of the column is denoted by v(z), so that v(z) = v0(z) when P = 0. Moment equilibrium of the free body diagram for a segment of the column shown in figure 11.13 is

Fig. 11.12 Load-displacement responses of the two-bar truss from linear and nonlinear analyses.

Fig. 11.13 FBD of the right-hand part of a pinned-pinned column.

The bending moment in the column is zero under no load, so we write the material law for bending as

where ϕ0(z) is the rotation of the initial shape of the column. For small slopes of the slightly deflected column the rotations are related to the lateral displacements by

Hence, the bending moment becomes

Substitute the bending moment from eq. (11.80) into the moment equilibrium equation (11.77) to get

Equation (11.81) is arranged to the form

where  . Take the initial shape of the column

. Take the initial shape of the column  , where a1 is the amplitude of the initial shape at midspan. Then the differential equation for v(z) is

, where a1 is the amplitude of the initial shape at midspan. Then the differential equation for v(z) is

The boundary conditions are  . The solution of the differential equation (11.83) subject to boundary conditions is

. The solution of the differential equation (11.83) subject to boundary conditions is

The term  where the critical load of the perfect structure is

where the critical load of the perfect structure is  . It is convenient to measure the deflection of the imperfect column under load with respect to its original unloaded state. That is, let δ define the additional displacement at midspan by

. It is convenient to measure the deflection of the imperfect column under load with respect to its original unloaded state. That is, let δ define the additional displacement at midspan by  . Hence,

. Hence,

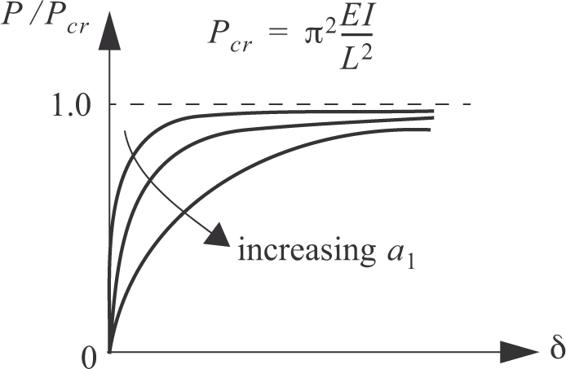

The load-displacement response is sketched in figure 11.14. Note that  as P→Pcr for a1 ≠ 0. That is, for a non-zero value of the imperfection amplitude, the displacement gets very large as the axial force approaches the buckling load of the perfect column. Also, the imperfect column deflects in the direction of imperfection (e.g., if a1 > 0, then δ > 0).

as P→Pcr for a1 ≠ 0. That is, for a non-zero value of the imperfection amplitude, the displacement gets very large as the axial force approaches the buckling load of the perfect column. Also, the imperfect column deflects in the direction of imperfection (e.g., if a1 > 0, then δ > 0).

Fig. 11.14 Load-deflection response plots for geometrically imperfect columns.

An arbitrary initial shape is represented by a Fourier Sine series as

Timoshenko and Gere (1961) show the solution for  is

is

For P < Pcr as P→Pcr, the first term dominates the solution for δ(z). Thus, for P near

The buckling behavior of a long, straight column subject to centric axial compression (the perfect column) is classified as stable symmetric bifurcation. As such it is imperfection insensitive. Refer to the discussions in article 10.1.5 on page 272 and article 10.2.1 on page 275. Even for a well manufactured column whose geometric imperfections are small, and with the load eccentricity small, the displacements become excessive as the axial compressive force P approaches the critical load  of the perfect column. Hence, the critical load determined from the analysis of the perfect column is meaningful in practice.

of the perfect column. Hence, the critical load determined from the analysis of the perfect column is meaningful in practice.

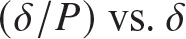

11.4.1 Southwell plot

Rearrange eq. (11.88) as follows:  , then

, then  . Divide the last by P to get

. Divide the last by P to get

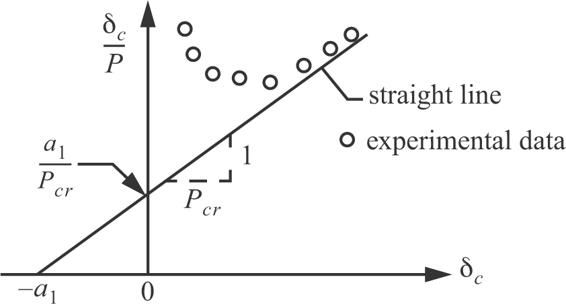

We plot δc∕P versus δc from eq. (11.89) in figure 11.15, which is called the Southwell plot (Southwell, 1932).1 The Southwell plot is very useful for determining  from test data in the elastic range. As

from test data in the elastic range. As  ,

,  , δ becomes large and the data (

, δ becomes large and the data ( ) tends to plot on a straight line. Extrapolating this straight line back to toward the ordinate axis (δ∕P) one can estimate a1 and

) tends to plot on a straight line. Extrapolating this straight line back to toward the ordinate axis (δ∕P) one can estimate a1 and  . It is more difficult to determine

. It is more difficult to determine  by the load-deflection curve obtained in experiments as illustrated in figure 11.16.

by the load-deflection curve obtained in experiments as illustrated in figure 11.16.

Fig. 11.15 Southwell plot.

Fig. 11.16 Load-deflection plot from test data.

11.5 Column design curve

Consider the pinned-pinned uniform column whose critical load is given by  . Let A denote the cross-sectional area of the column. At the onset of buckling the critical stress is defined as

. Let A denote the cross-sectional area of the column. At the onset of buckling the critical stress is defined as

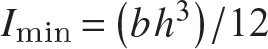

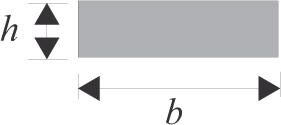

The second area moment is I = r2A, where r denotes the minimum radius of gyration of the cross section. For the rectangular section shown in figure 11.17,  and A = bh, so that

and A = bh, so that  , where

, where  . Thus, the critical stress becomes

. Thus, the critical stress becomes

and L∕r is called the slenderness ratio. The slenderness ratio is the column length divided by a cross-sectional dimension significant to bending.

Fig. 11.17

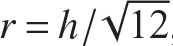

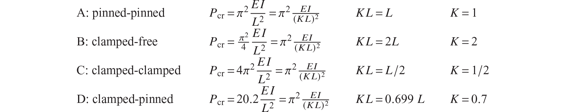

For any set of boundary conditions define the effective length KL by the formula

The effective lengths for the four standard boundary conditions are as follows:

The definition of effective length uses case A boundary conditions as a reference. The concept of effective length accounts for boundary conditions other than simple support, or pinned-pinned end conditions.

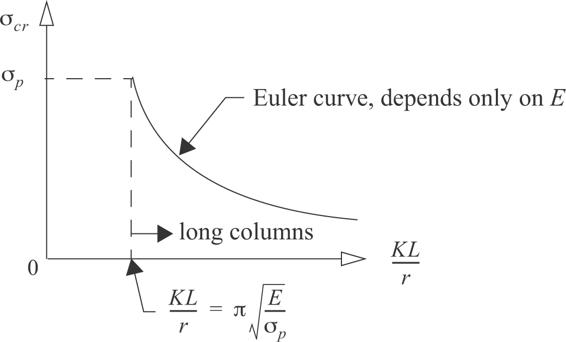

The column curve is a plot of the critical stress versus the effective slenderness ratio (i.e.,  ). For elastic column buckling under all boundary conditions

). For elastic column buckling under all boundary conditions

which is a hyperbola that depends only on the modulus of elasticity E of the material. This equation governing elastic buckling is called the Euler curve, and columns that buckle in the elastic range are called long columns. See figure 11.18.

Fig. 11.18 Column curve for elastic buckling.

11.5.1 Inelastic buckling

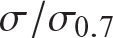

The column curve equation, eq. (11.93), is valid up to the proportional limit of the material, denoted by σp. The proportional limit is defined as the stress where the compressive stress-strain curve of the material deviates from a straight line. If the stress at the onset of buckling is greater than the proportional limit, then the column is said to be of intermediate length, and the Euler formula, eq. (11.93), cannot be used. The proportional limit is difficult to measure from test data because its definition is based on the deviation from linearity. In particular, the compressive stress-strain curves for aluminum alloys typically used in aircraft construction do not exhibit a very pronounced linear range. For aluminum alloys a material law developed by Ramberg and Osgood (1943) is often used to describe the nonlinear compressive stress-strain curve. The Ramberg-Osgood equation is a three-parameter fit to the compressive stress-strain curves of aluminum alloys. From the experimental compressive stress-strain curve the slope near the origin is the modulus of elasticity E. The stress where the secant line drawn from the origin with slope 0.85 E intersects the stress-strain curve is denoted σ0.85.The stress where a second secant line drawn from the origin with slope 0.7 E intersects the stress-strain curve is denoted by σ0.7. These data are depicted in figure 11.19. Note that the compressive normal strain corresponding to the stress σ0.7 is usually about the 0.2 percent offset yield strain for the material. Hence, stress σ0.7 is close to the 0.2 percent offset yield stress of the aluminum alloy. The Ramberg-Osgood equation is

Fig. 11.19 Data used to fit the compression stress-strain curve of aluminum alloys.

where the shape parameter n is given by

Equation (11.94) is re-written as

and is plotted as  versus

versus  for various values of the shape parameter n, This plot is shown in figure 11.20. Some approximate values for common aluminum alloys are listed in table 11.3.

for various values of the shape parameter n, This plot is shown in figure 11.20. Some approximate values for common aluminum alloys are listed in table 11.3.

Table 11.3 Ramberg-Osgood parameters for selected aluminum alloys

|

AL |

E in 10 |

|

n |

|---|---|---|---|

|

2014-T6 |

10.6 |

60 |

20 |

|

2024-T4 |

10.6 |

48 |

10 |

|

6061-T6 |

10.0 |

40 |

30 |

|

7075-T6 |

10.4 |

73 |

20 |

Fig. 11.20 A normalized plot of the Ramberg-Osgood material law for various values of the shape parameter n.

From the Ramberg-Osgood equation, eq. (11.94), the local slope of the compressive stress-strain curve is determined as a function of the stress. This slope of the compressive stress-strain curve is called the tangent modulus (i.e.,  where Et is the tangent modulus). Differentiate eq. (11.94) to get

where Et is the tangent modulus). Differentiate eq. (11.94) to get

Thus, the tangent modulus is

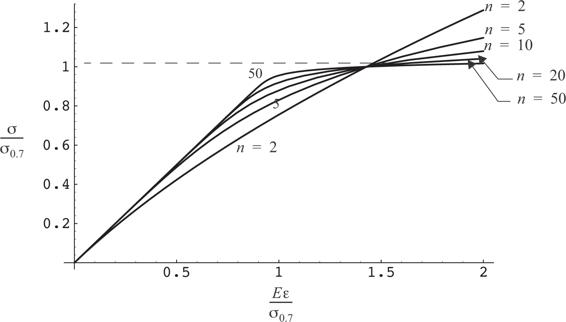

For intermediate length columns it has been demonstrated by extensive testing that the critical stress is reasonably well predicted using the Euler curve, eq. (11.93), with the modulus of elasticity replaced by the tangent modulus. This inelastic buckling analysis is called the tangent modulus theory. That is,

Now substitute eq. (11.98) for the tangent modulus in the latter equation, noting that  , to get

, to get

After division by σ0.7, eq. (11.100) can be written as

A plot of the column curve given by eq. (11.101) is shown in figure 11.21.

Fig. 11.21 Column curves for a Ramberg-Osgood material law with different shape factors.

11.6 Bending of thin plates

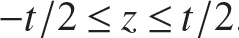

Recall that bars and beams are structural elements characterized by having two orthogonal dimensions, say the thickness and width, that are small compared to the third orthogonal dimension, the length. Thin plates, both flat and curved, are common structural elements in flight vehicle structures, and they are characterized by one dimension being small, say the thickness, with respect to the other two orthogonal dimensions, say the width and length. A thin, rectangular, flat plate shown in figure 11.22 is referenced to Cartesian axes x, y, and z, where the x-direction is parallel to the length, the y-direction is parallel to the width, and the z-axis is parallel to the thickness of the plate. We denote the length of the plate by a, the width by b, and the thickness by t, and  ,

,  , and

, and  . The plane with z = 0 is the midsurface, or reference surface, of the plate.

. The plane with z = 0 is the midsurface, or reference surface, of the plate.

Fig. 11.22 Illustration of the nomenclature and primary stresses for a flat, rectangular plate.

A beam resists the transverse loads, or lateral loads, primarily by the longitudinal normal stress σx, and the so-called lateral stresses σy, σz, τyx, and τyz are assumed to be negligible. Transverse loads, acting in the z-direction applied to the plate are primarily resisted by the in-plane stress components σx, σy, and τxy. Transverse shear stresses τxz and τyz are necessary for force equilibrium in the z-direction under transverse loads, but are smaller in magnitude with respect to the in-plane stresses. In plate theory, the transverse normal stress σz is very small with respect to the in-plane normal stresses and, hence, is neglected. Bending of thin plates is discussed in many texts on plate theory; for example, see Ugural and Fenster (2003). Only some elements of the plate bending theory are discussed here. The assumptions of the linear theory for thin plates are as follows:

1. The deflection of the midsurface is small with respect to the thickness of the plate, and the slope of the deflected midsurface is much less than unity.

2. Straight lines normal to the midsurface in the undeformed plate remain straight and normal to the midsurface in the deformed plate, and do not change length.

3. The normal stress component σz is negligible with respect to the in-plane normal stresses and is neglected in Hooke’s law.

Now consider the deformation, or strains, caused by the normal stresses. Hooke’s law for the normal stresses and strains in a three-dimensional state of stress is

where E is the modulus of elasticity and v is Poisson’s ratio. From assumption 3 the thickness normal stress  is assumed negligible and is set to zero in Hooke’s law. From assumption 2 the thickness normal strain εz = 0, because the line element normal to the midsurface does not change length. Since the normal stress σz is also assumed to vanish, the third of eq. (11.102) leads to a contradiction. Hence, the third equation of Hooke’s law is neglected. The material law for the in-plane normal strains and stresses for thin plates is

is assumed negligible and is set to zero in Hooke’s law. From assumption 2 the thickness normal strain εz = 0, because the line element normal to the midsurface does not change length. Since the normal stress σz is also assumed to vanish, the third of eq. (11.102) leads to a contradiction. Hence, the third equation of Hooke’s law is neglected. The material law for the in-plane normal strains and stresses for thin plates is

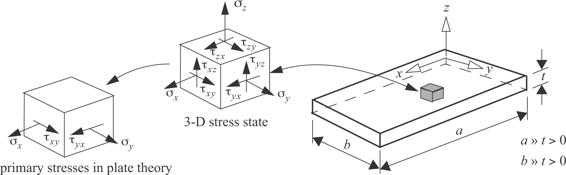

Consider two cases of pure bending of a plate or a beam subject to moment M. In the first case the cross section is compact with dimension b nearly equal to thickness t, and in the second case dimension b is much larger than thickness t. In the first case the structure is a beam, and in the second case it is a plate. In pure bending the neutral axis of the beam deforms into an arc of a circle with radius ρ, and the normal strain in the x-direction is  . Note that we assumed that the x-axis coincided with the neutral axis in the undeformed beam. Hence, longitudinal line elements above the neutral axis, z > 0, are stretched, and line elements below the neutral axis, z < 0, are compressed. In the case of a beam, the normal stress in the y-direction, σy, is also very small and is neglected with respect to the longitudinal normal stress σx. That is, the beam resists the applied bending moment by the longitudinal normal stress σx. Since σy = 0, we get from Hooke’s law, eq. (11.103), that

. Note that we assumed that the x-axis coincided with the neutral axis in the undeformed beam. Hence, longitudinal line elements above the neutral axis, z > 0, are stretched, and line elements below the neutral axis, z < 0, are compressed. In the case of a beam, the normal stress in the y-direction, σy, is also very small and is neglected with respect to the longitudinal normal stress σx. That is, the beam resists the applied bending moment by the longitudinal normal stress σx. Since σy = 0, we get from Hooke’s law, eq. (11.103), that

Hence, the longitudinal normal stress is the modulus of elasticity times the longitudinal normal strain, and the normal strain in the y-direction is just Poisson’s ratio times the longitudinal normal strain. The form of the last expression for εy in eq. (11.104) shows that the line elements in the cross section parallel to the y-axis before deformation also bend into circular arcs. The line element parallel to the y-direction at z = 0 in the undeformed beam has a radius of curvature of  in the deformed beam. This transverse curvature is called anticlastic curvature, and is illustrated in figure 11.23.

in the deformed beam. This transverse curvature is called anticlastic curvature, and is illustrated in figure 11.23.

Fig. 11.23 Pure bending of a beam in the x- z plane and the associated anticlastic curvature of its cross section.

Now consider pure bending of a plate under the same moment M, where now the dimension b is much larger than thickness t. In this case experiments show that the transverse line elements remain straight over the central section of the plate, so that the anticlastic curvature is suppressed. In this central section of the plate the transverse normal stress εy is non-zero. However, the transverse normal stress must vanish at the free edges at y = 0 and y = b, so that anticlastic curvature develops only in narrow zones near the free edges to adjust to vanishing of the normal stress σy at the free edges. In the central portion of the plate, the associated normal strain is zero. The suppression of anticlastic curvature is characterized by the vanishing of the normal strain εy. Hence from Hooke’s law, eq. (11.103), for εy = 0 we get

Since the denominator in the expression for σx is positive but less than unity, the plate is stiffer than the beam owing to the presence of the non-zero transverse normal stress σy to help in resisting the applied moment. Compare eqs. (11.104) and (11.105) for the normal stress σx. The quantity  is an effective modulus of the plate.

is an effective modulus of the plate.