6.17: The Wilson-GIW (1979) Models

- Page ID

- 31057

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)6.20.1 The Wilson-GIW (1979) Model for Fully Stratified Flow

6.20.1.1 Introduction

The Wilson et al. (1992), (1997) and (2006) model for the hydraulic transport of solids in pipelines is a widely used model for the sliding bed regime. A theoretical background of the model has been published piece by piece in a number of articles over the years. A variety of information provided in these publications makes the model difficult to reconstruct. Wilson (1979) first published his theory in 1979. Riet et al. (1995) & (1996) and Miedema et al. (2002) tried to reproduce the Wilson (1979) model.

A good understanding of the model structure is inevitable for the user who wants to extend or adapt the model to specific slurry flow conditions. The aim of this chapter is to summarize the model theory and submit the results of the numerical analysis carried out on the various model configurations. The numerical results show some differences when compared with the nomographs presented in the literature as the graphical presentations of the generalised model outputs. Model outputs are sensitive on a number of input parameters and on a model configuration used. This chapter contains an overview of a theory of the Wilson et al. (1992) two-layer model (2LM) as it has been published in a number of articles over the years. Results are presented from the model computation. The results provide an insight to the behavior of the mathematical model.

The model is based on an equilibrium of forces acting on the bed. Driving forces and resisting forces can be distinguished. The driving forces on the bed are the shear forces on the top of the bed and the force resulting from the pressure times the bed cross section. The pressure is the result of the sum of the shear force on the pipe wall in the restricted area above the bed and the shear force on the bed, divided by the cross section of this restricted area. The resisting forces are the force as a result of the sliding friction between the bed and the pipe wall and the viscous friction force of the liquid between the particles in the bed and the pipe wall. When the sum of the driving forces equals the sum of the resisting forces, the so called Limit of Stationary Deposit Velocity is reached. At line speeds below the Limit of Stationary Deposit Velocity, the bed is stationary and does not move, because the driving forces are smaller than the maximum resisting forces (maximum if the sliding friction would be fully mobilized, which is not the case at line speeds below the Limit of Stationary Deposit Velocity). At line speeds above the Limit of Stationary Deposit Velocity, the bed is sliding with a speed that is increasing with increasing line speed.

6.20.1.2 The Basic Equations for Flow and Geometry

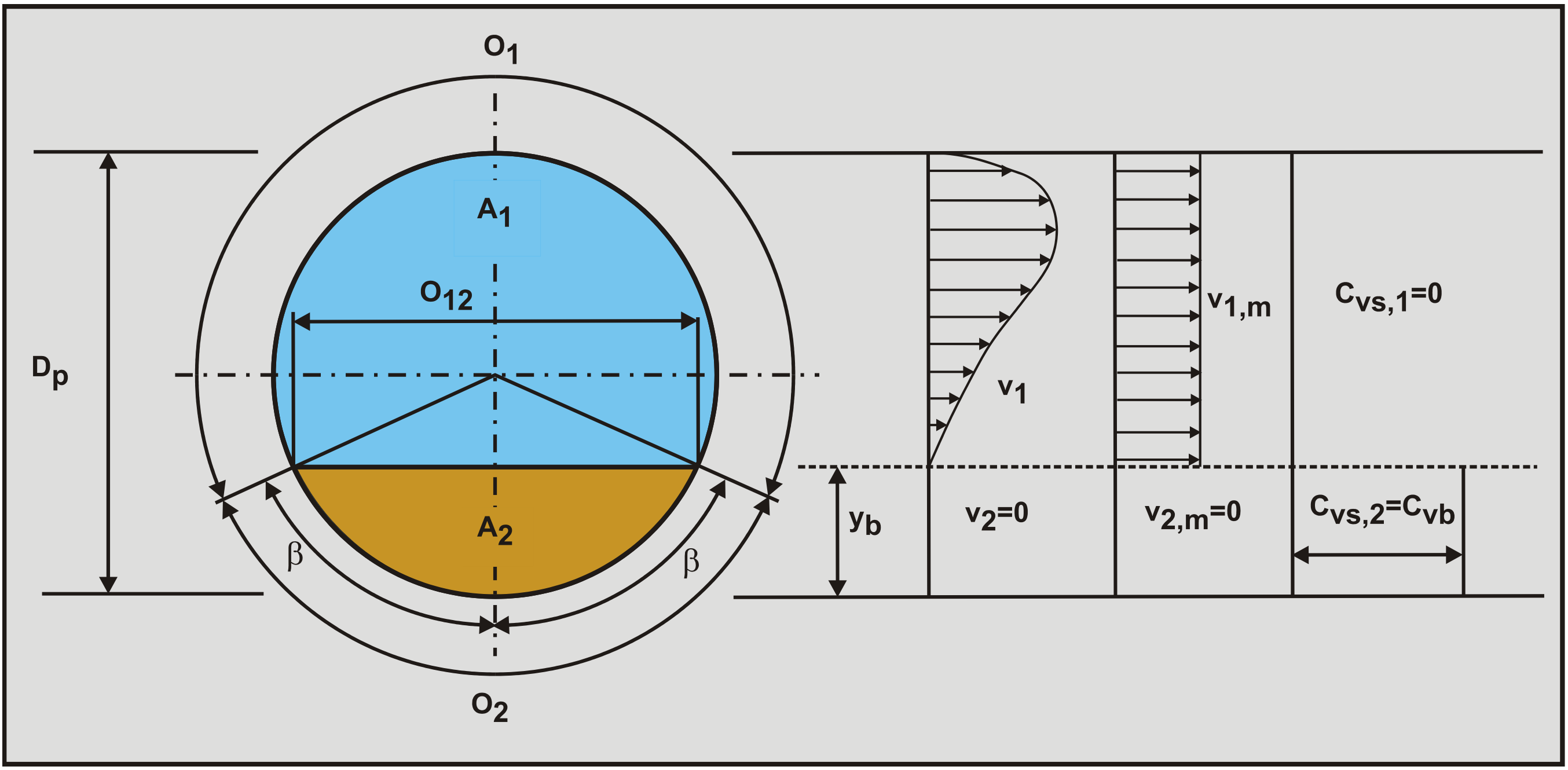

In order to understand the model, first all the geometrical parameters are defined. The cross section of the pipe with a particle bed as defined in the Wilson et al. (1992) two layer model has been illustrated by Figure 6.20-1.

The geometry is defined by the following equations.

The length of the liquid in contact with the whole pipe wall if there is no bed is:

\[\ \mathrm{O}_{\mathrm{p}}=\pi \cdot \mathrm{D}_{\mathrm{p}}\]

The length of the liquid or the suspension in contact with the pipe wall:

\[\ \mathrm{O}_{1}=\mathrm{D}_{\mathrm{p}} \cdot(\pi-\beta)\]

The length of the fixed or sliding bed in contact with the wall:

\[\ \mathrm{O}_{2}=\mathrm{D}_{\mathrm{p}} \cdot \boldsymbol{\beta}\]

The top surface length of the fixed or sliding bed:

\[\ \mathrm{O}_{12}=\mathrm{D}_{\mathrm{p}} \cdot \sin (\beta)\]

The cross sectional area Ap of the pipe is:

\[\ \mathrm{A}_{\mathrm{p}}=\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{\mathrm{2}}\]

The cross sectional area A2 of the fixed or sliding bed is:

\[\ \mathrm{A}_{2}=\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2} \cdot\left(\frac{\boldsymbol{\beta}-\sin (\beta) \cdot \cos (\beta)}{\pi}\right)\]

The cross sectional area A1 above the bed, where the liquid or the suspension is flowing, also named the restricted area:

\[\ \mathrm{A}_{\mathrm{1}}=\mathrm{A}_{\mathrm{p}}-\mathrm{A}_{2}\]

The hydraulic diameter of the cross-section of the pipeline above the bed DH as function of the bed height, is equal to four times the cross sectional area divided by the wetted perimeter:

\[\ \mathrm{D}_{\mathrm{H}, \mathrm{1}}=\frac{\mathrm{4} \cdot \mathrm{A}_{\mathrm{1}}}{\mathrm{O}_{\mathrm{1}}+\mathrm{O}_{\mathrm{1 2}}} \quad\text{ or simplified: }\quad \mathrm{D}_{\mathrm{H}, \mathrm{1}}=\sqrt{\frac{\mathrm{4} \cdot \mathrm{A}_{\mathrm{1}}}{\pi}}\]

The volume balance gives a relation between the line speed vls, the velocity in the restricted area above the bed vr or v1 and the velocity of the bed vb or v2.

\[\ \mathrm{v}_{\mathrm{l s}} \cdot \mathrm{A}_{\mathrm{p}}=\mathrm{v}_{\mathrm{1}} \cdot \mathrm{A}_{\mathrm{1}}+\mathrm{v}_{2} \cdot \mathrm{A}_{2}\]

Thus the velocity in the restricted area above the bed is:

\[\ \mathrm{v}_{1}=\frac{\mathrm{v}_{\mathrm{l s}} \cdot \mathrm{A}_{\mathrm{p}}-\mathrm{v}_{2} \cdot \mathrm{A}_{2}}{\mathrm{A}_{1}}\]

Or the velocity of the bed is:

\[\ \mathrm{v}_{2}=\frac{\mathrm{v}_{\mathrm{l} \mathrm{s}} \cdot \mathrm{A}_{\mathrm{p}}-\mathrm{v}_{\mathrm{1}} \cdot \mathrm{A}_{\mathrm{1}}}{\mathrm{A}_{2}}\]

6.20.1.3 The Shear Stresses Involved

In order to determine the forces involved, first the shear stresses involved have to be determined. The general equation for the shear stresses is:

\[\ \tau=\rho_{1} \cdot \mathrm{u}_{*}^{2}=\frac{\lambda_{\mathrm{l}}}{4} \cdot \frac{1}{2} \cdot \rho_{1} \cdot \mathrm{v}^{2}\]

The force F on the pipe wall over a length ΔL is now:

\[\ \mathrm{F}=\tau \cdot \pi \cdot \mathrm{D}_{\mathrm{p}} \cdot \Delta \mathrm{L}=\frac{\lambda_{\mathrm{l}}}{\mathrm{4}} \cdot \frac{\mathrm{1}}{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{v}^{2} \cdot \pi \cdot \mathrm{D}_{\mathrm{p}} \cdot \Delta \mathrm{L}\]

The pressure Δp required to push the solid-liquid mixture through the pipe equals the force divided by the cross-section:

\[\ \Delta \mathrm{p}=\frac{\mathrm{F}}{\mathrm{A}_{\mathrm{p}}}=\frac{\frac{\lambda_{\mathrm{l}}}{\mathrm{4}} \cdot \frac{\mathrm{1}}{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{v}^{2} \cdot \pi \cdot \mathrm{D}_{\mathrm{p}} \cdot \Delta \mathrm{L}}{\frac{\pi}{4} \cdot \mathrm{D}_{\mathrm{p}}^{2}}=\lambda_{\mathrm{l}} \cdot \frac{\Delta \mathrm{L}}{\mathrm{D}_{\mathrm{p}}} \cdot \frac{\mathrm{1}}{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{v}^{2}\]

This is the well-known Darcy Weisbach equation. Over the whole range of Reynolds numbers above 2320 (5000<Re<100.000) the Swamee Jain equation gives a good approximation for the friction coefficient:

\[\ \lambda_{\mathrm{l}}=\frac{1.325}{\left(\ln \left(\frac{0.27 \cdot \varepsilon}{\mathrm{D}_{\mathrm{p}}}+\frac{5.75}{\mathrm{Re}^{0.9}}\right)\right)^{2}} \quad \text{ with: }\quad \mathrm{Re}=\frac{\mathrm{v} \cdot \mathrm{D}_{\mathrm{p}}}{v_{\mathrm{l}}}\]

This gives for the shear stress on the pipe wall for clean water:

\[\ \tau_{\mathrm{l}}=\frac{\lambda_{\mathrm{l}}}{4} \cdot \frac{1}{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{v}_{ \mathrm{ls}}^{2} \quad\text{ with: }\quad \lambda_{\mathrm{l}}=\frac{1.325}{\left(\ln \left(\frac{0.27 \cdot \varepsilon}{\mathrm{D}_{\mathrm{p}}}+\frac{5.75}{\mathrm{Re}^{0.9}}\right)\right)^{2}} \quad\text{ and }\quad \mathrm{Re}=\frac{\mathrm{v}_{\mathrm{ls}} \cdot \mathrm{D}_{\mathrm{p}}}{v_{\mathrm{l}}}\]

For the flow in the restricted area, the shear stress between the liquid and the pipe wall is:

\[\ \tau_{1,\mathrm{l}}=\frac{\lambda_{1}}{4} \cdot \frac{1}{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{v}_{1}^{2} \quad\text{ with: }\quad \lambda_{1}=\frac{1.325}{\left(\ln \left(\frac{0.27 \cdot \varepsilon}{\mathrm{D}_{\mathrm{H}, 1}}+\frac{5.75}{\mathrm{R} \mathrm{e}^{0.9}}\right)\right)^{2}} \quad\text{ and }\quad \mathrm{R} \mathrm{e}=\frac{\mathrm{v}_{1} \cdot \mathrm{D}_{\mathrm{H}, 1}}{v_{\mathrm{l}}}\]

For the flow in the restricted area, the shear stress between the liquid and the bed is:

\[\ \tau_{12,\mathrm{l}}=\frac{\lambda_{12}}{4} \cdot \frac{1}{2} \cdot \rho_{\mathrm{l}} \cdot\left(\mathrm{v}_{1}-\mathrm{v}_{2}\right)^{2} \quad\text{ with: }\quad \lambda_{12}=\frac{\alpha \cdot 1.325}{\left(\ln \left(\frac{0.27 \cdot \mathrm{d}}{\mathrm{D}_{\mathrm{H}, 1}}+\frac{5.75}{\mathrm{R} \mathrm{e}^{0.9}}\right)\right)^{2}} \quad\text{ and }\quad \operatorname{Re}=\frac{\mathrm{v}_{1} \cdot \mathrm{D}_{\mathrm{H}, 1}}{v_{\mathrm{l}}}\]

The factor α as used by Wilson et al. (1992) is 2 or 2.75, depending on the publication and version of his book. Televantos et al. (1979) used a factor of 2.

For the flow between the liquid in the bed and the pipe wall, the shear stress between the liquid and the pipe wall is:

\[\ \tau_{2,\mathrm{l}}=\frac{\lambda_{2}}{4} \cdot \frac{1}{2} \cdot \rho_{\mathrm{l}} \cdot \mathrm{v}_{2}^{2} \quad\text{ with: }\quad \lambda_{2}=\frac{1.325}{\left(\ln \left(\frac{0.27 \cdot \varepsilon}{\mathrm{d}}+\frac{5.75}{\mathrm{Re}^{0.9}}\right)\right)^{2}}\quad\text{ and }\quad\mathrm{Re}=\frac{\mathrm{v}_{2} \cdot \mathrm{d}}{v_{\mathrm{l}}}\]

Wilson et al. (1992) assume that the sliding friction is the result of a hydrostatic normal force between the bed and the pipe wall multiplied by the sliding friction factor. The average shear stress as a result of the sliding friction between the bed and the pipe wall, according to the Wilson et al. (1992) normal stress approach is:

\[\ \tau_{2, \mathrm{sf}}=\frac{\mu_{\mathrm{sf}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \mathrm{A}_{\mathrm{p}}}{\beta \cdot \mathrm{D}_{\mathrm{p}}} \cdot \frac{\mathrm{2} \cdot(\sin (\beta)-\beta \cdot \cos (\beta))}{\pi}\]

It is however also possible that the sliding friction force results from the weight of the bed multiplied by the sliding friction factor. For low volumetric concentrations, there is not much difference between the two methods, but at higher volumetric concentrations there is. The average shear stress as a result of the sliding friction between the bed and the pipe wall, according to the weight normal stress approach is:

\[\ \tau_{2, \mathrm{sf}}=\frac{\mu_{\mathrm{sf}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vb}} \cdot \mathrm{A}_{\mathrm{p}}}{\beta \cdot \mathrm{D}_{\mathrm{p}}} \cdot \frac{(\beta-\sin (\beta) \cdot \cos (\beta))}{\pi}\]

6.20.1.4 The Forces Involved

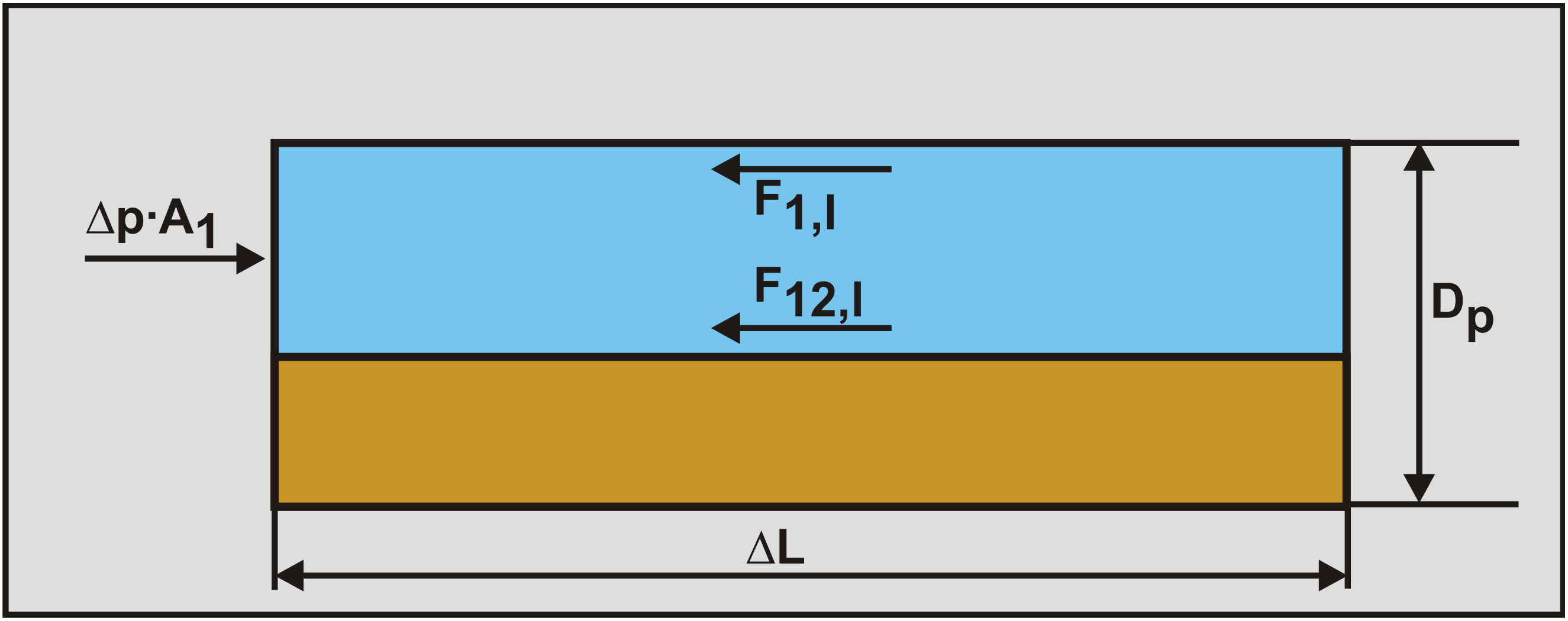

First the equilibrium of the forces on the liquid above the bed is determined. This is necessary to find the correct hydraulic gradient. The resisting shear force on the pipe wall O1 above the bed is:

\[\ \mathrm{F}_{\mathrm{1}, \mathrm{l}}=\tau_{\mathrm{1}, \mathrm{l}} \cdot \mathrm{O}_{\mathrm{1}} \cdot \mathrm{\Delta} \mathrm{L}\]

The resisting shear force on the bed surface O12 betweeen the restricted area and the top of the bed is:

\[\ \mathrm{F}_{12,\mathrm{l}}=\tau_{12,\mathrm{l}} \cdot \mathrm{O}_{12} \cdot \Delta \mathrm{L}\]

The pressure Δp on the liquid above the bed is:

\[\ \Delta \mathrm{p}=\Delta \mathrm{p}_{2}=\Delta \mathrm{p}_{1}=\frac{\tau_{1,\mathrm{l}} \cdot \mathrm{O}_{\mathrm{1}} \cdot \Delta \mathrm{L}+\tau_{12,\mathrm{l}} \cdot \mathrm{O}_{12} \cdot \Delta \mathrm{L}}{\mathrm{A}_{1}}=\frac{\mathrm{F}_{1,\mathrm{l}}+\mathrm{F}_{12, \mathrm{l}}}{\mathrm{A}_{1}}\]

The force equilibrium on the liquid above the bed is shown in Figure 6.20-2.

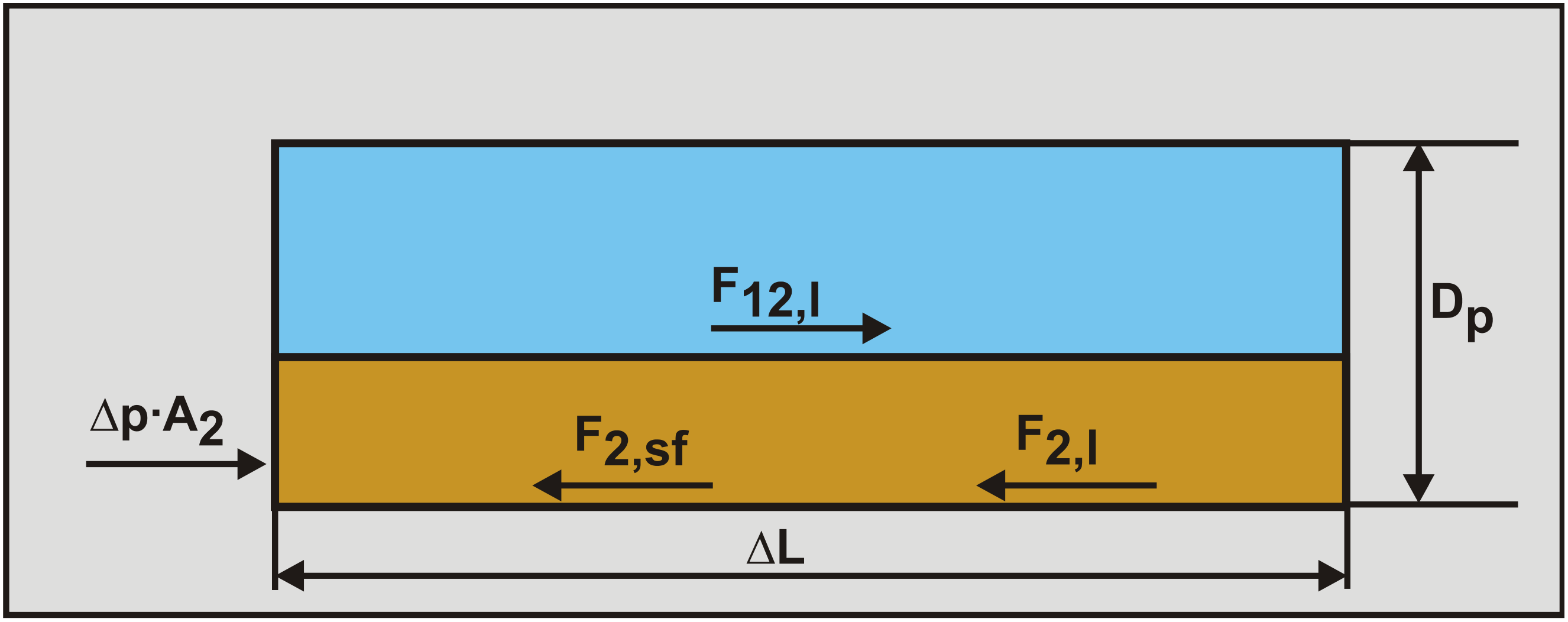

Secondly the equilibrium of forces on the bed is determined as is shown in Figure 6.20-3.

The driving shear force on the bed surface is:

\[\ \mathrm{F}_{\mathrm{1 2}, \mathrm{l}}=\tau_{\mathrm{1 2}, \mathrm{l}} \cdot \mathrm{O}_{\mathrm{1 2}} \cdot \mathrm{\Delta} \mathrm{L}\]

The driving force resulting from the pressure Δp on the bed is:

\[\ \mathrm{F}_{2, \mathrm{p r}}=\Delta \mathrm{p} \cdot \mathrm{A}_{2}\]

The resisting force between the bed and the pipe wall due to sliding friction is:

\[\ \mathrm{F}_{2, \mathrm{sf}}=\tau_{2, \mathrm{sf}} \cdot \mathrm{O}_{2} \cdot \Delta \mathrm{L}\]

The resisting shear force between the liquid in the bed and the pipe wall is:

\[\ \mathrm{F}_{2, \mathrm{l}}=\tau_{2, \mathrm{l}} \cdot \mathrm{O}_{2} \cdot \mathrm{n} \cdot \Delta \mathrm{L}\]

This shear force is multiplied by the porosity n, in order to correct for the fact that the bed consists of a combination of particles and water. There is an equilibrium of forces when:

\[\ \mathrm{F}_{\mathrm{1 2}, \mathrm{l}}+\mathrm{F}_{\mathrm{2}, \mathrm{p r}}=\mathrm{F}_{\mathrm{2}, \mathrm{s f}}+\mathrm{F}_{\mathrm{2}, \mathrm{l}}\]

Below the Limit of Stationary Deposit Velocity, the bed is not sliding and the force F2,l equals zero. Since the problem is implicit with respect to the velocities v1 and v2, it has to be solved with an iteration process.

In the case when the relative concentration Cvr=Cvs/Cvb or Cvr=Cvt/Cvb equals 1, the resistance equals the plug hydraulic gradient, according to:

\[\ \mathrm{i}_{\mathrm{p l u g}}=\mathrm{2} \cdot {\mu}_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v b}}\]

Wilson et al. (1992) defined the maximum Limit of Stationary Deposit Velocity as vsm.

The graphs in the following chapter are determined for uniform sands, not taking into account grading. In real life there will almost always be grading, resulting in slightly different curves, depending on the grading.

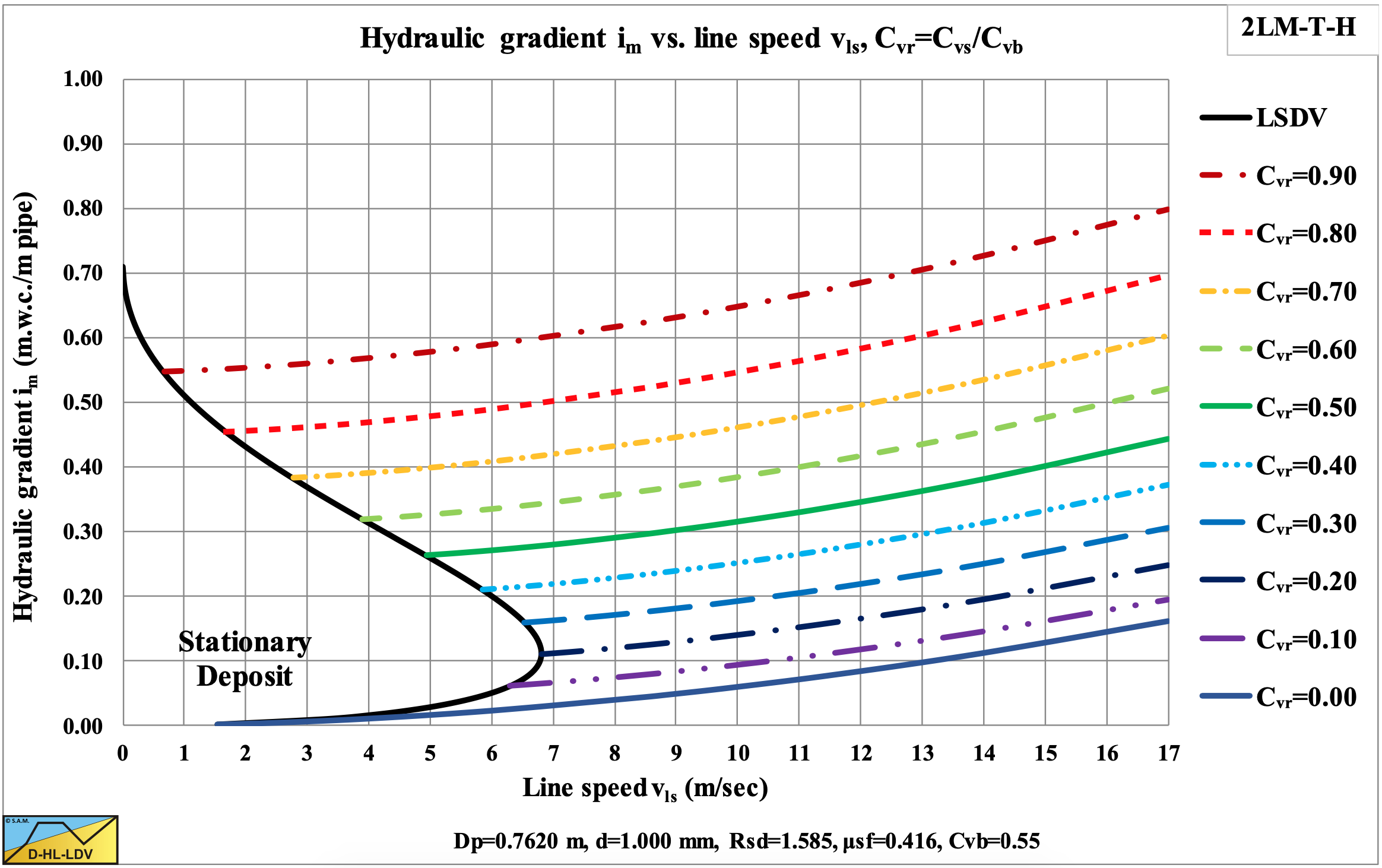

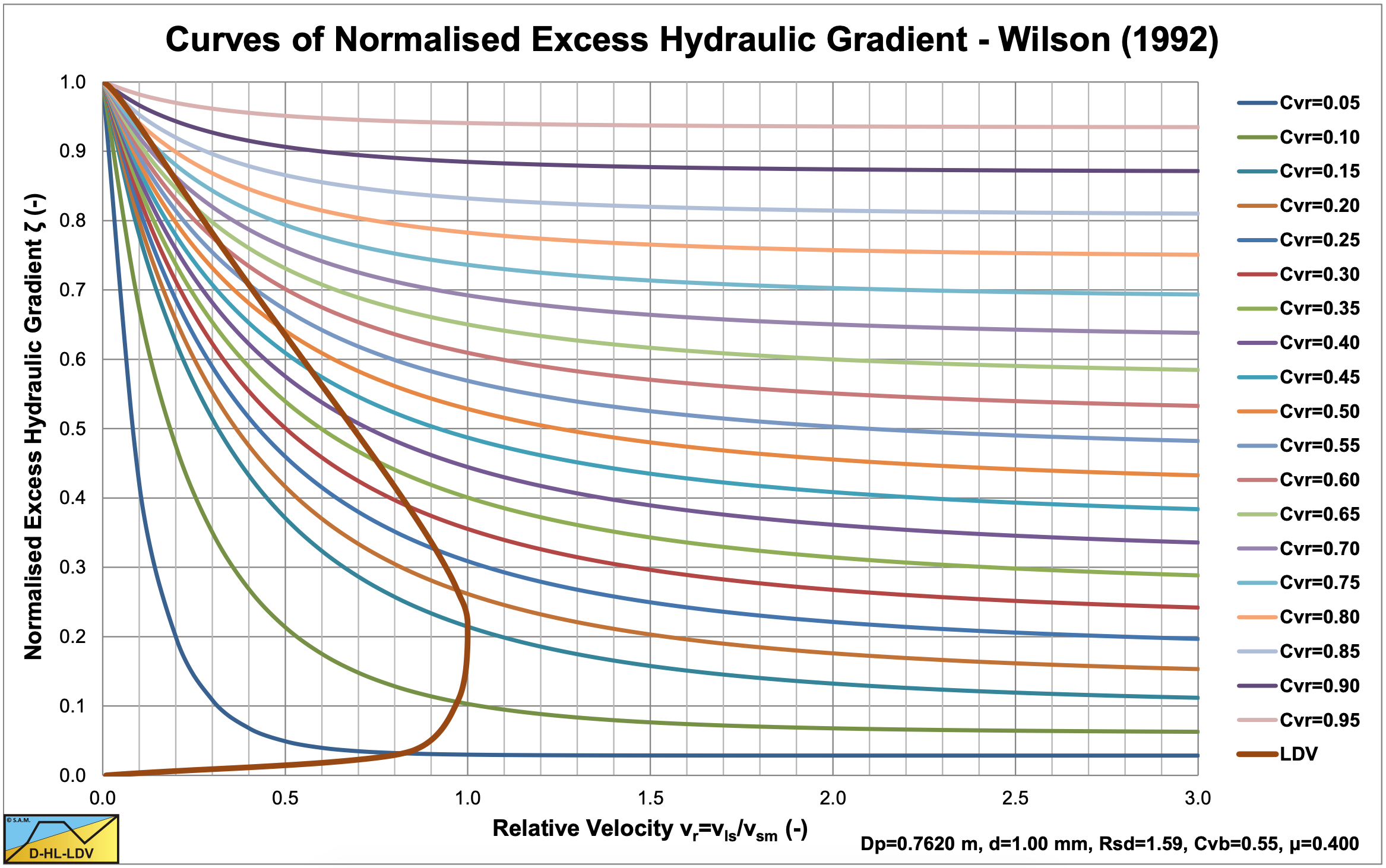

6.20.1.5 Output with the Wilson et al. (1992) Hydrostatic Stress Approach

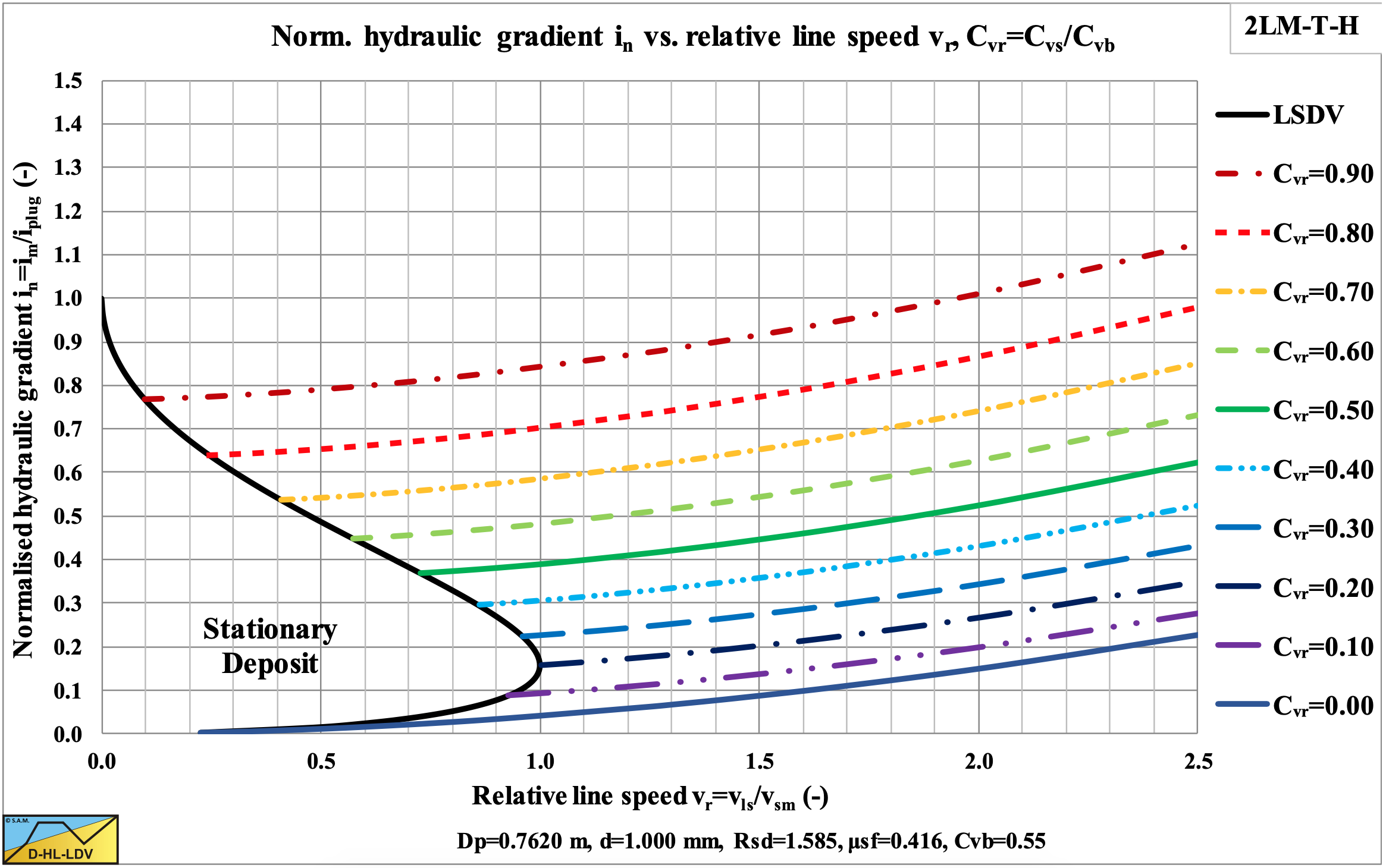

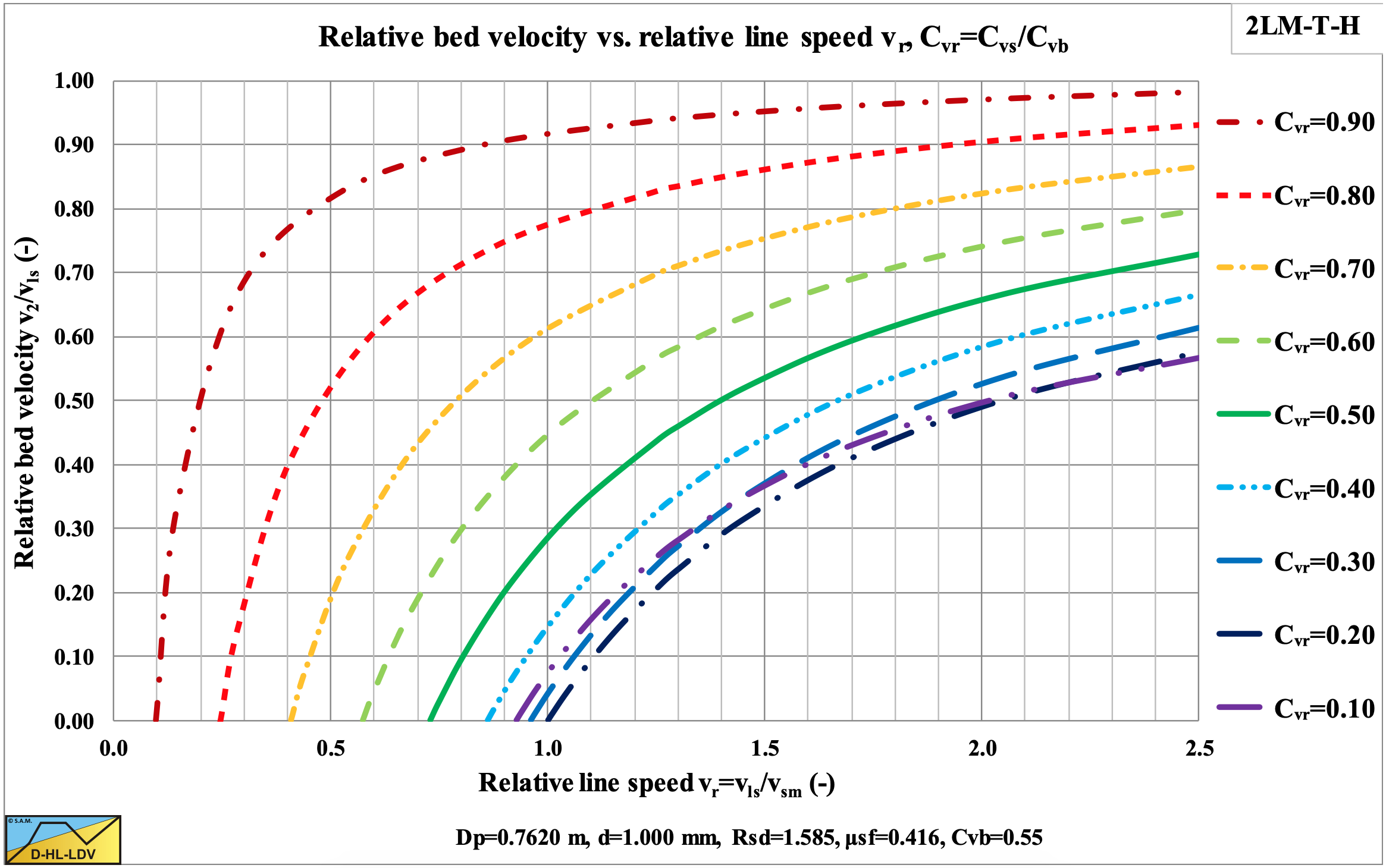

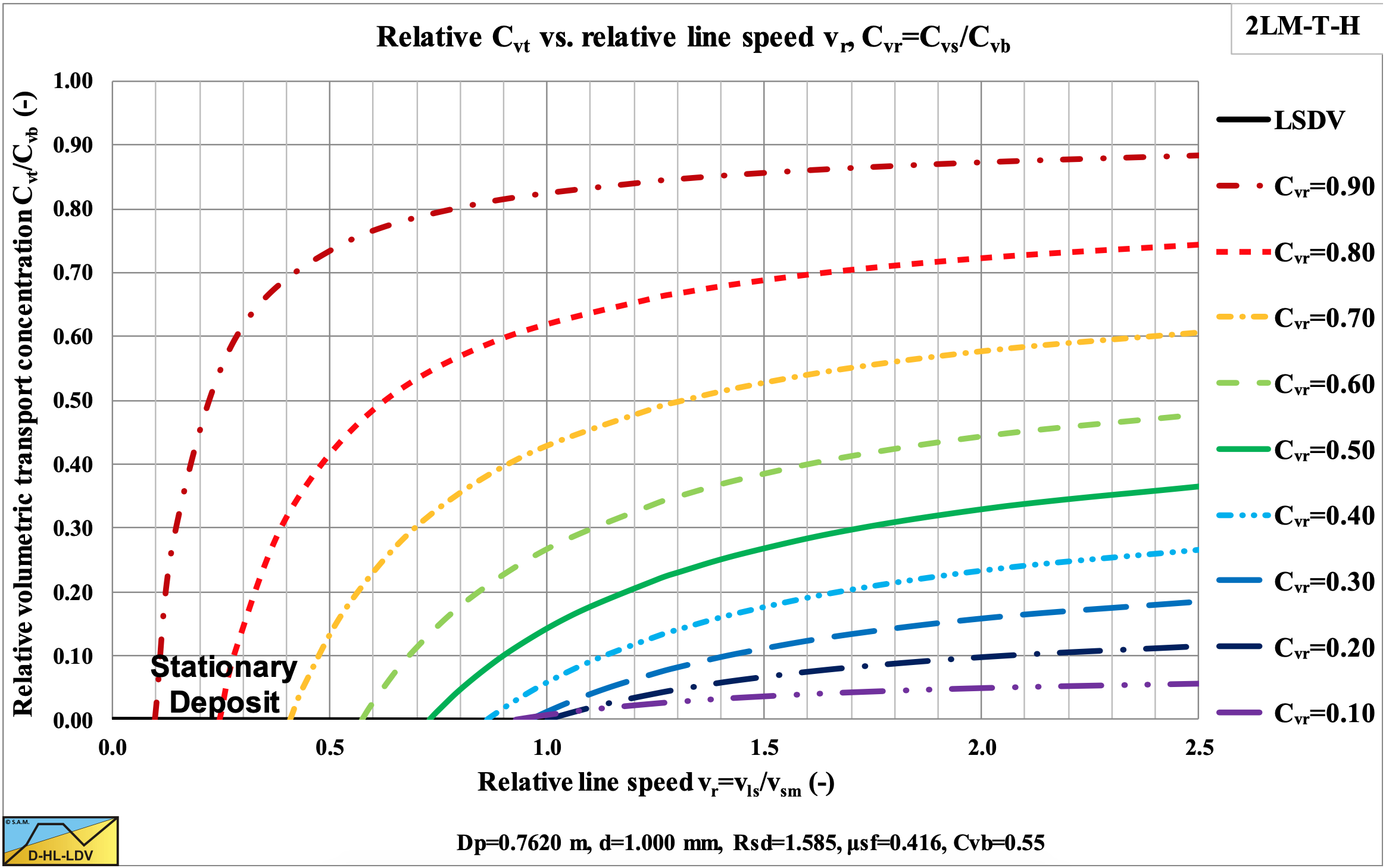

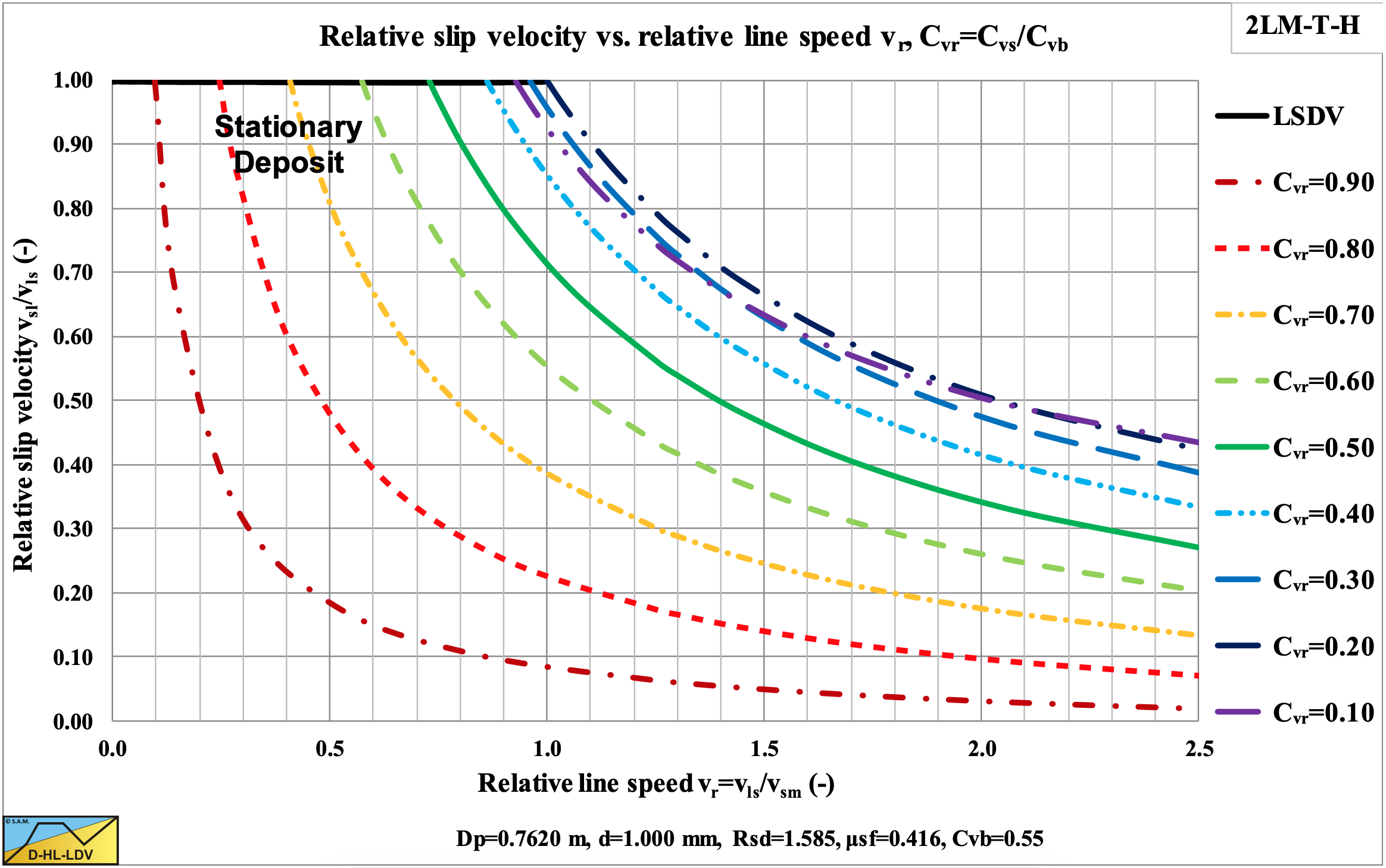

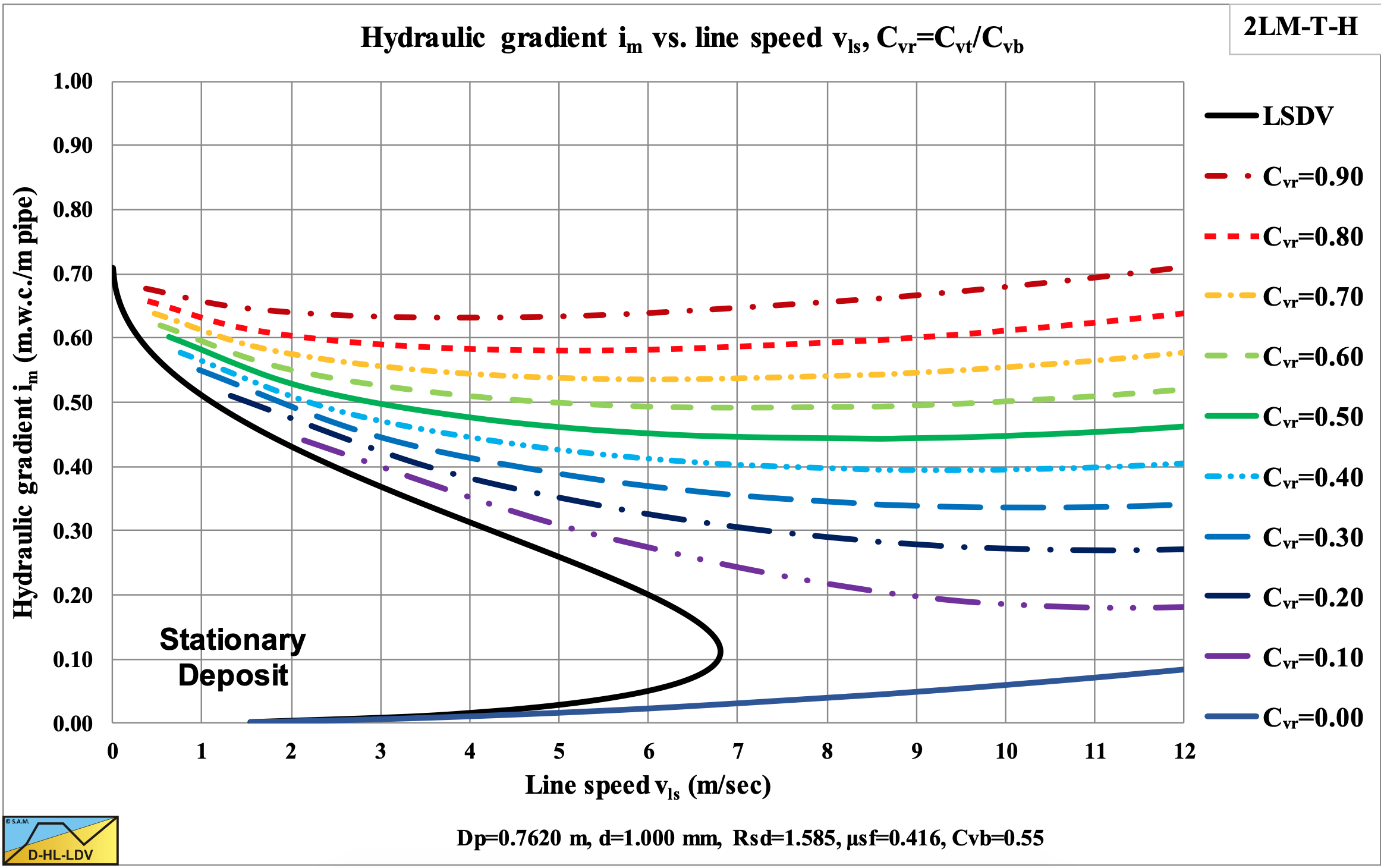

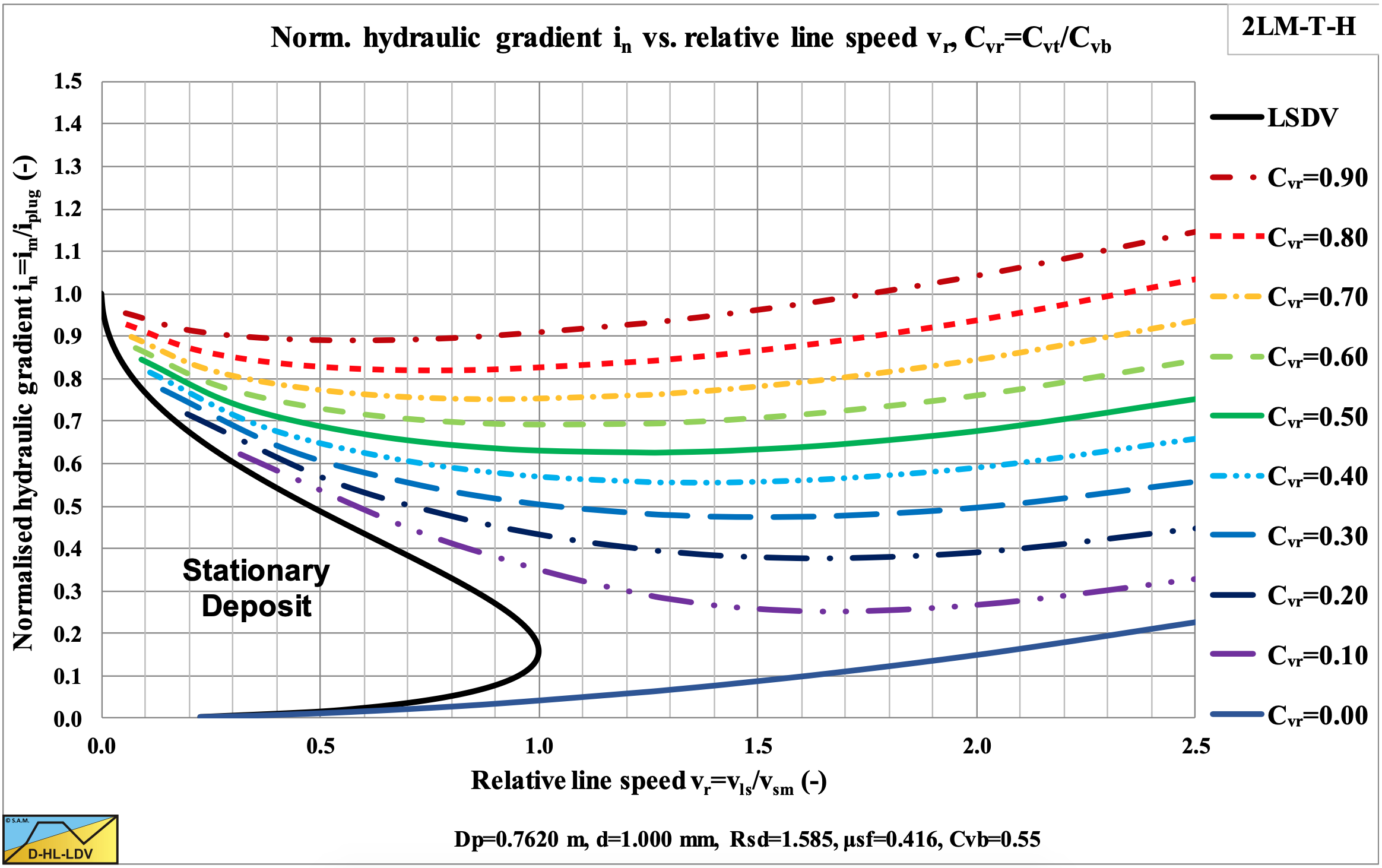

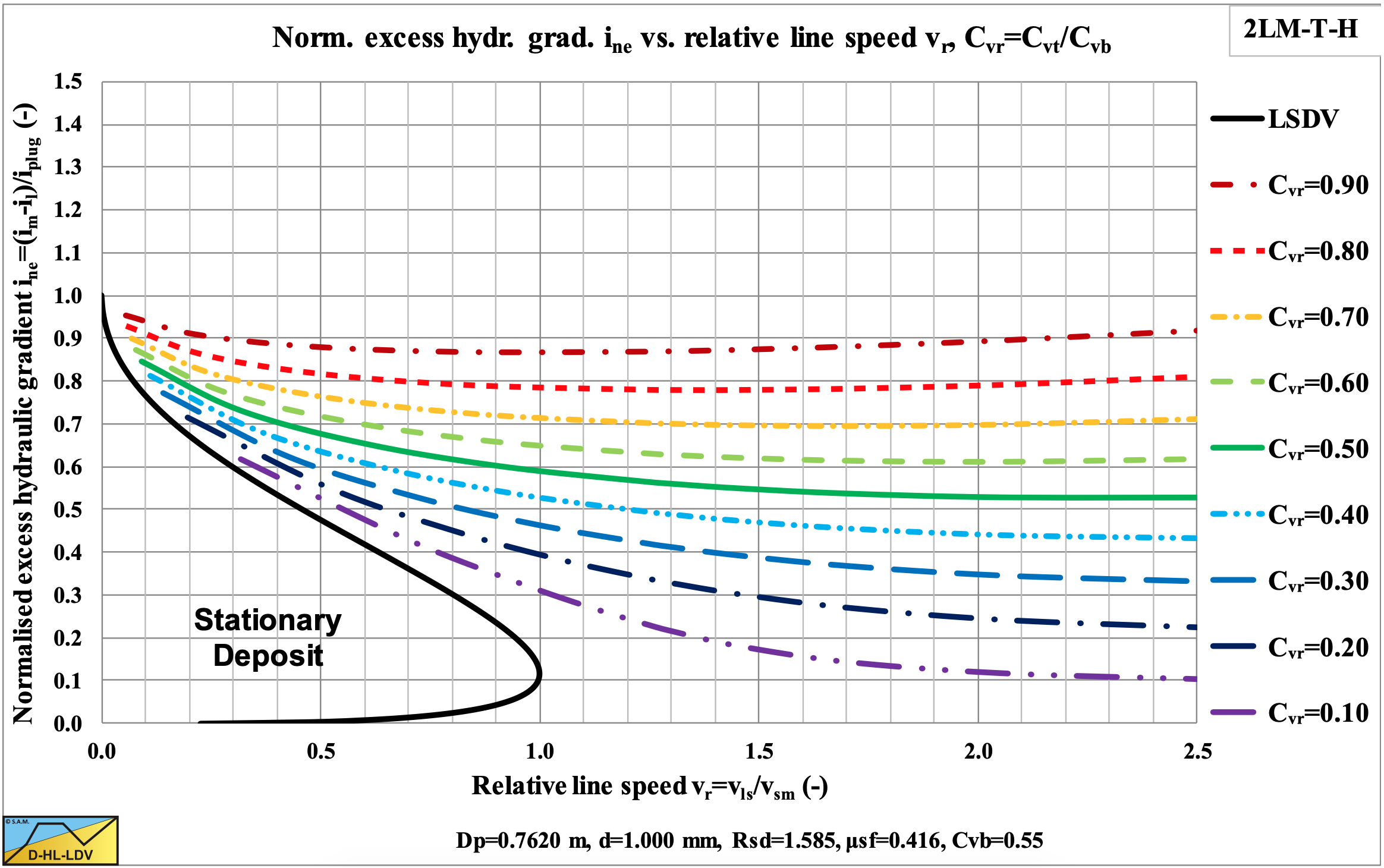

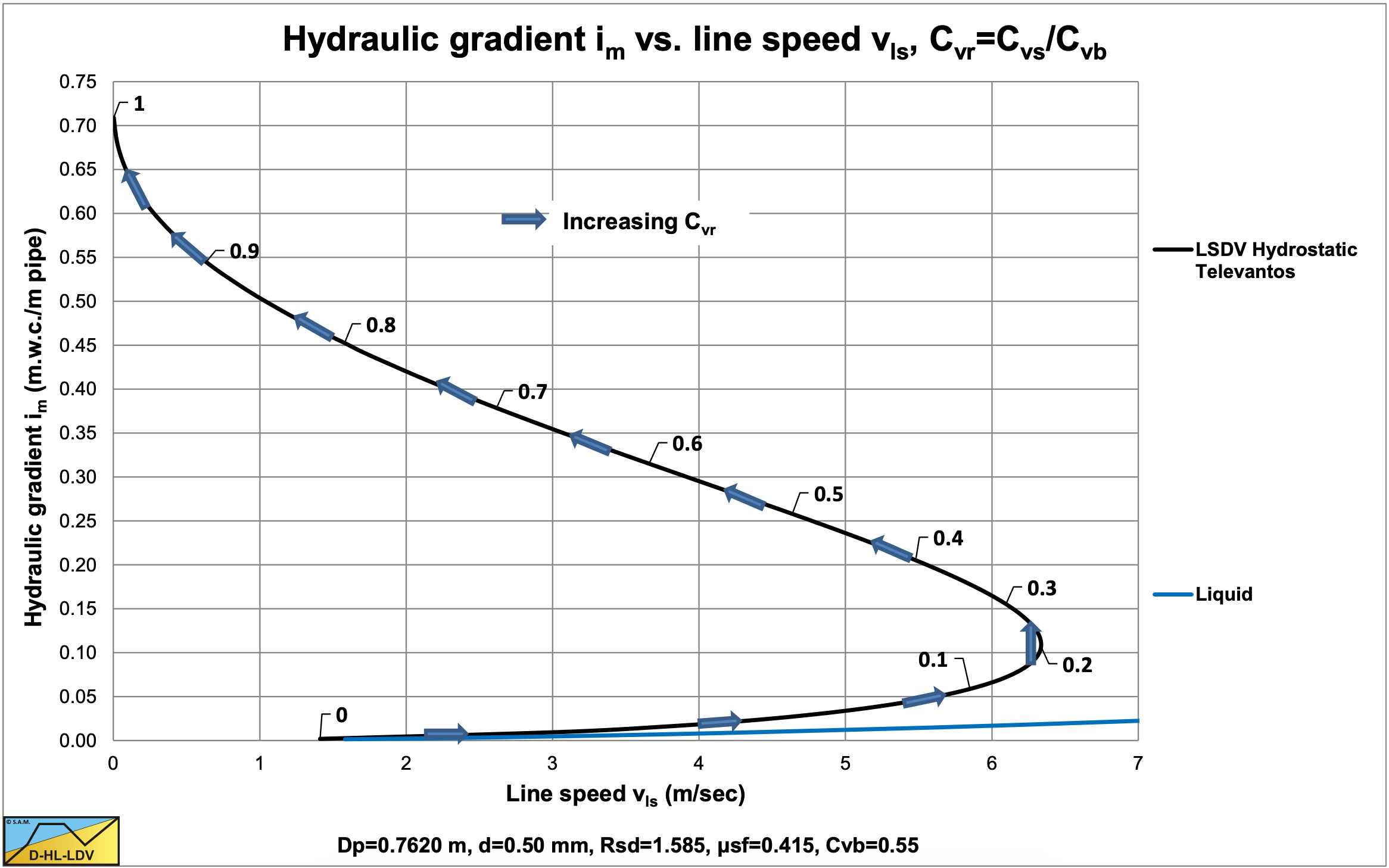

The direct outputs of the model are the hydraulic gradient and the bed velocity as shown in Figure 6.20-4, Figure 6.20-5 and Figure 6.20-6. Based on the bed velocity the delivered volumetric concentration Cvt and the slip velocity vsl can be determined as is shown in Figure 6.20-7 and Figure 6.20-8. In Figure 6.20-5 the axis are made dimensionless (normalized) by dividing the hydraulic gradient by the plug hydraulic gradient and dividing the line speed vls by the maximum Limit of Stationary Deposit Velocity vsm. The relative bed velocity increases with increasing relative spatial volumetric concentration and even becomes 1 for a relative spatial concentration of 1, the bed concentration. The transport or delivered volumetric concentration also increases with increasing relative spatial volumetric concentration, but also with an increasing line speed.

Once the delivered volumetric concentration is known, points with equal delivered concentration can be connected and hydraulic gradient curves with constant delivered volumetric concentration can be constructed as is shown in Figure 6.20-9 and Figure 6.20-10. It should be mentioned that these curves do not intersect with the limit of stationary deposit velocity curve, since there the bed has no velocity, so the delivered concentration is zero. The curves with small delivered concentrations follow the Limit of Stationary Deposit Velocity curve at the upper side. Figure 6.20-8 shows that the slip velocity decreases with an increasing spatial volumetric concentration and even goes to zero if the relative spatial concentration goes to 1, the bed concentration.

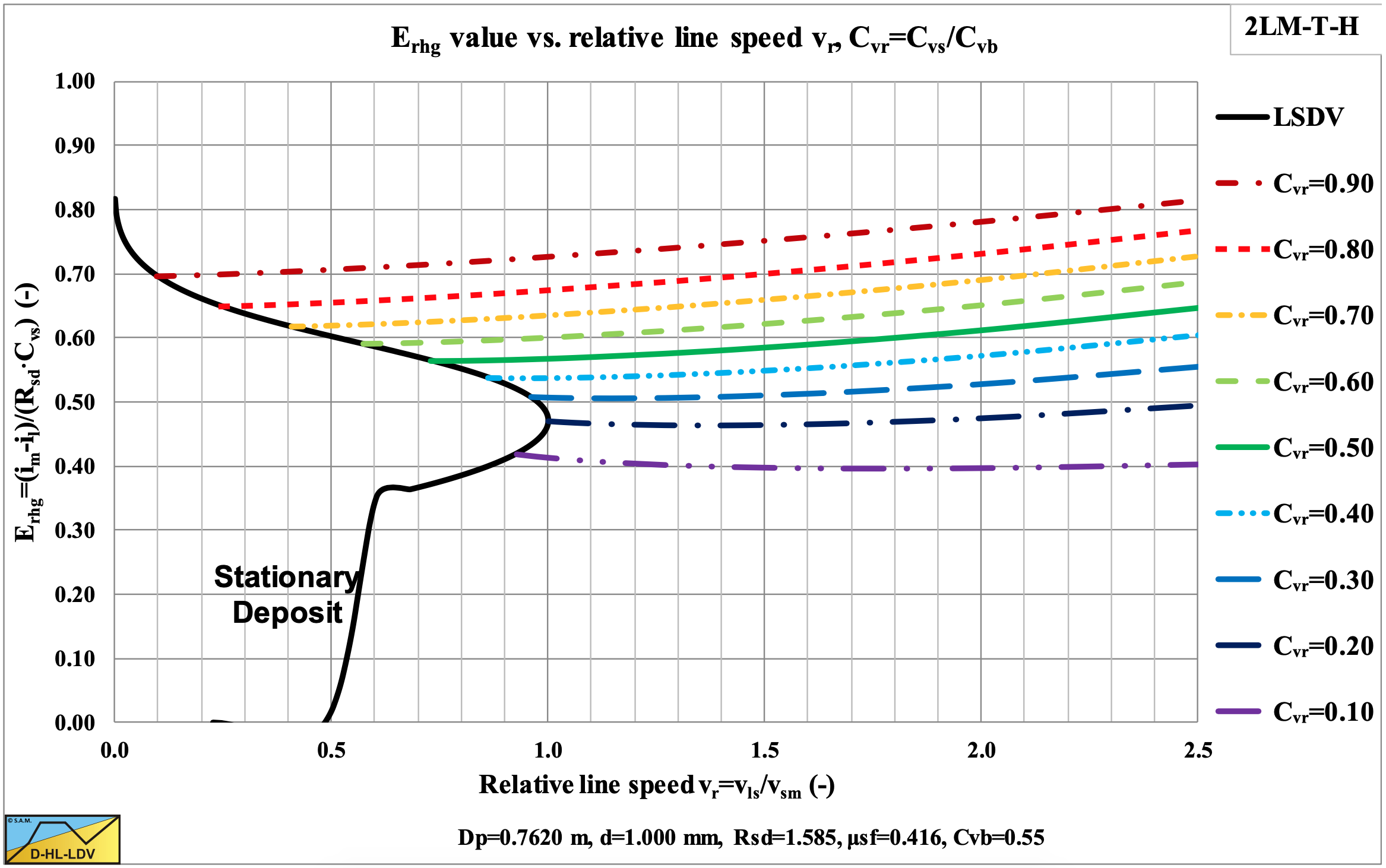

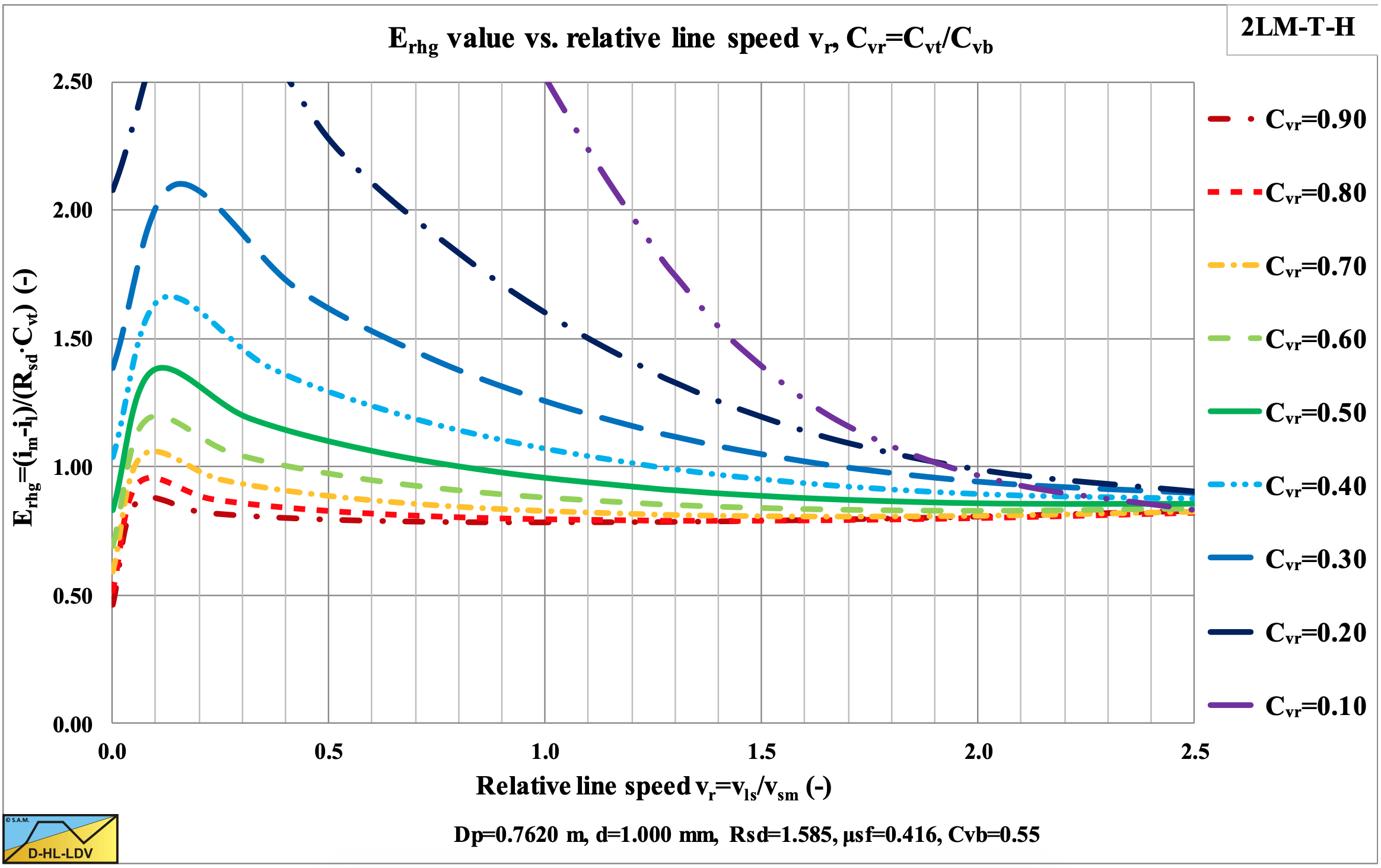

Figure 6.20-11 and Figure 6.20-12 show the relative excess hydraulic gradient curves for constant spatial volumetric concentration curves and for constant delivered volumetric concentration curves. The constant spatial volumetric concentration curves are almost horizontal, but have a higher value for a higher relative spatial volumetric concentration, due to the hydrostatic pressure approach for the normal stresses between the bed and the pipe wall. For low relative spatial volumetric concentrations, the relative excess hydraulic gradient has a value close to the sliding friction coefficient μsf. A relative spatial volumetric concentration of 1 results in a relative excess hydraulic gradient of about 2 times the sliding friction coefficient.

Wilson et al. (1992) often show the excess hydraulic gradient divided (normalized) by the plug hydraulic gradient in their graphs, like in Figure 6.20-13. Their fit functions are also based on this type of graph.

6.20.1.6 The Fit Functions of Wilson et al. (1992)

Wilson et al. (1992) published the sliding bed model as a nomograph, using a set of parameters (μsf=0.4, Cvb=0.6 and a factor α=2.75 for the friction factor on top of the bed). The nomograph and the set of fit function for the normalized excess hydraulic gradient are based on constant volumetric transport concentration curves.

The normalized excess hydraulic gradient is defined as the mixture hydraulic gradient minus the liquid hydraulic gradient divided by the plug hydraulic gradient:

\[\ \zeta=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{i}_{\mathrm{p l u g}}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{2} \cdot \boldsymbol{\mu}_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}}}\]

The relative line speed is the ratio between the line speed and the maximum Limit of Stationary Deposit Velocity:

\[\ \mathrm{v}_{\mathrm{r}}=\frac{\mathrm{v}_{\mathrm{l s}}}{\mathrm{v}_{\mathrm{s m}}}\]

The relative volumetric transport concentration Cvr is:

\[\ \mathrm{C}_{\mathrm{v r}}=\frac{\mathrm{C}_{\mathrm{v t}}}{\mathrm{C}_{\mathrm{v b}}}\]

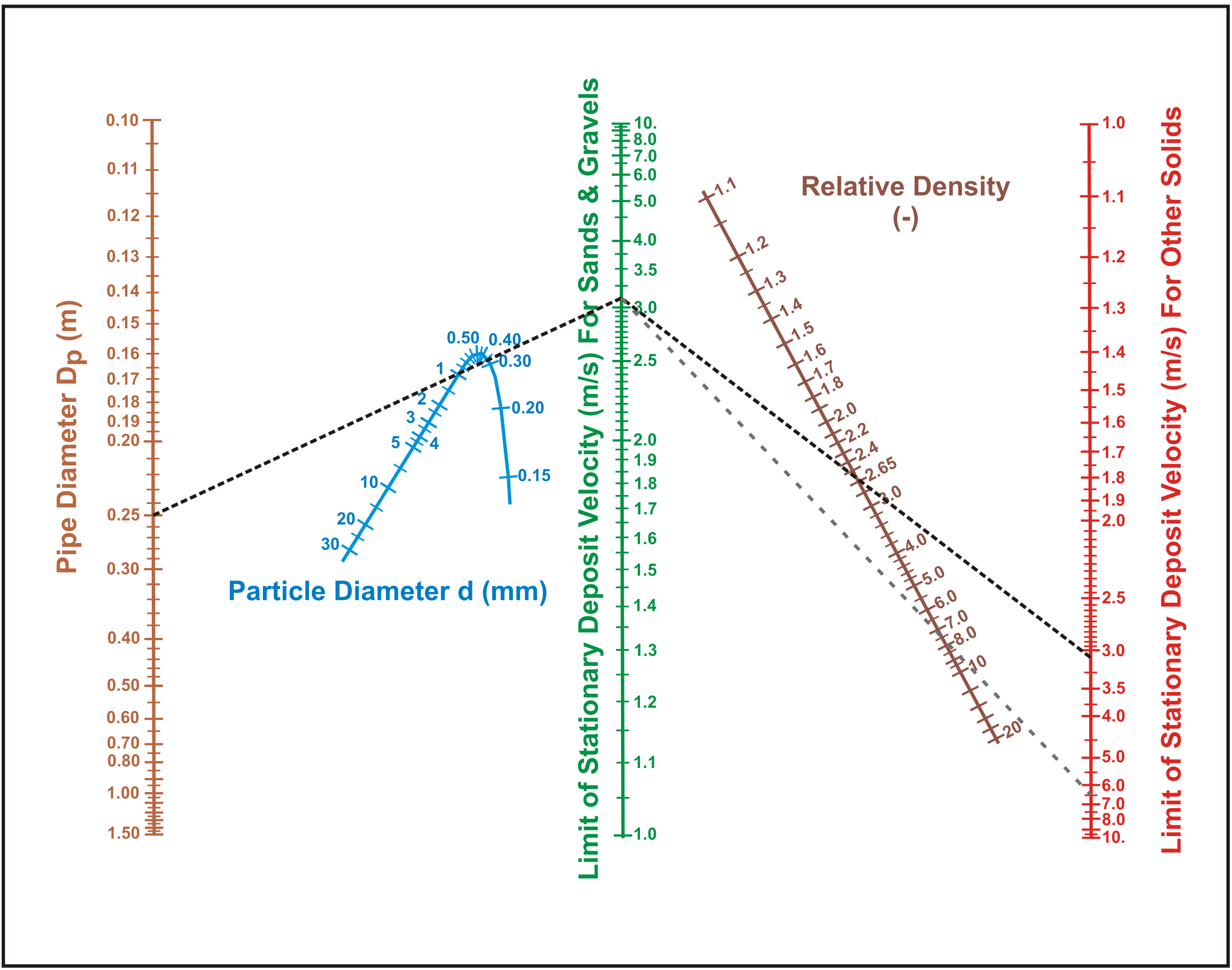

The maximum Limit of Stationary Deposit Velocity (LSDV) vsm can be estimated by (Matousek (2004)), with d in mm and Dp in m:

\[\ \mathrm{v}_{\mathrm{s m}}=\frac{\mathrm{8.8 } \cdot\left(\frac{\mu_{\mathrm{sf}} \cdot \mathrm{R}_{\mathrm{sd}}}{\mathrm{0 . 6 6}}\right)^{\mathrm{0 . 5 5}} \cdot \mathrm{D}_{\mathrm{p}}^{\mathrm{0 . 7}} \cdot \mathrm{d}^{\mathrm{1 . 7 5}}}{\mathrm{d}^{2}+\mathrm{0 . 1 1 \cdot D _ { \mathrm { p } } ^ { \mathrm { 0 . 7 } }}} \quad\text{ and }\quad \mathrm{F}_{\mathrm{L}}=\frac{\mathrm{v}_{\mathrm{s m}}}{\sqrt{\mathrm{2 \cdot \mathrm { g } \cdot \mathrm { R } _ { \mathrm { s d } } \cdot \mathrm { D } _ { \mathrm { p } }}}}\]

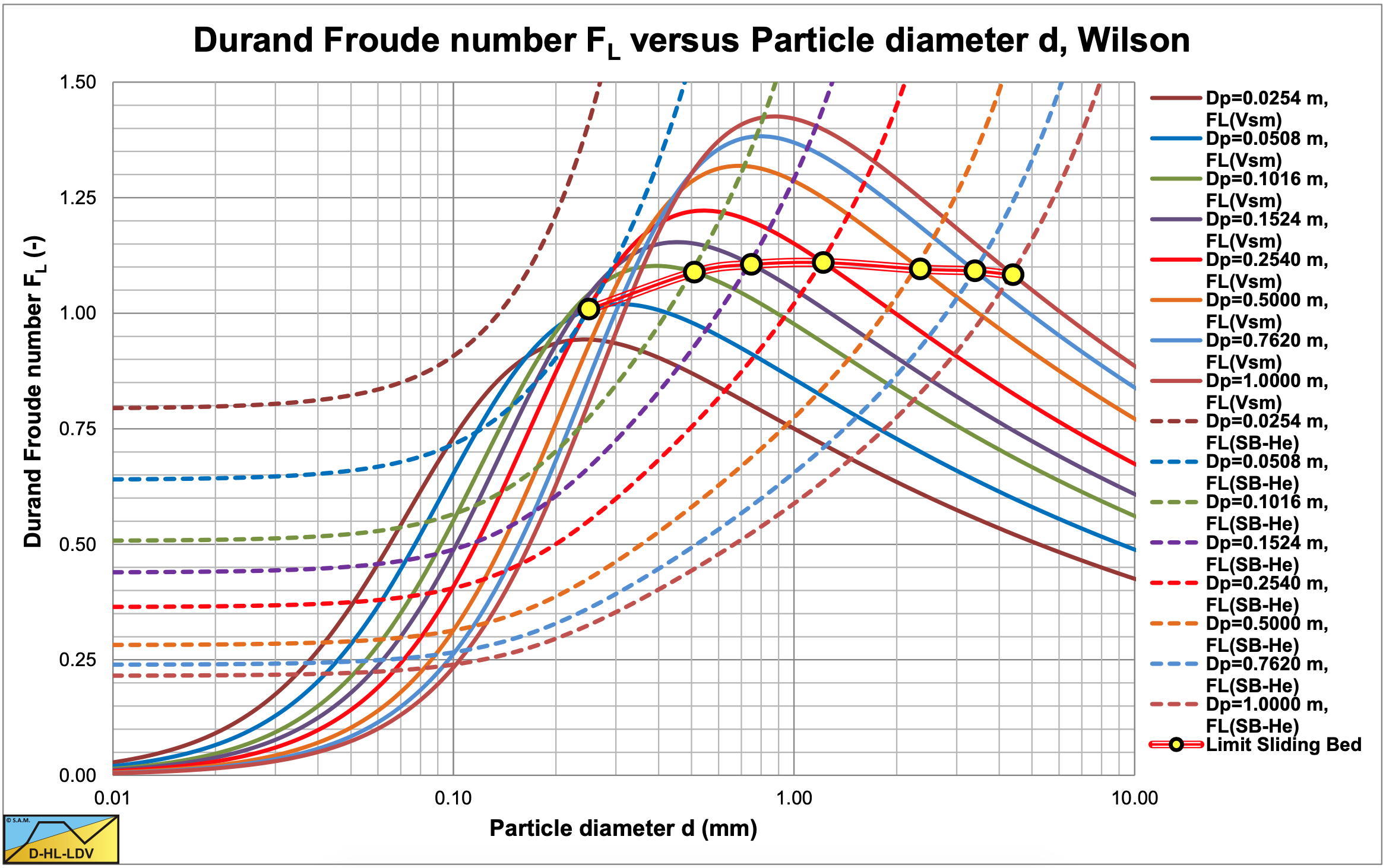

Figure 6.20-14 shows the Durand Froude number FL for a number of pipe diameters as a function of the particle diameter. The figure also shows the Durand Froude number of the intersection point of the (slightly modified) heterogeneous model with the sliding bed curve (Transition FB-He). If this intersection point is below the LSDV, a sliding bed will never occur, if it is above the LSDV a sliding bed will occur. The figure shows the particle diameter where the sliding bed will occur for each pipe diameter. Other heterogeneous models may give slightly different values.

In the smallest (Dp=1 inch and 2 inch) pipe a sliding bed will always occur. A pipe diameter of Dp=0.1016 m gives d=0.49 mm, Dp=0.1524 m gives d=0.78 mm, Dp=0.254 m gives d=1.3 mm, Dp=0.5 m gives d=2.65 mm, Dp=0.762 m gives d=3.8 mm. In the largest (Dp=1 m) pipe a sliding bed will occur for particles larger than about d=4.5 mm. The conclusion is, that one cannot just scale head losses, without knowing the flow regimes occurring. The demi-McDonald is shown in Figure 6.20-37 with an example.

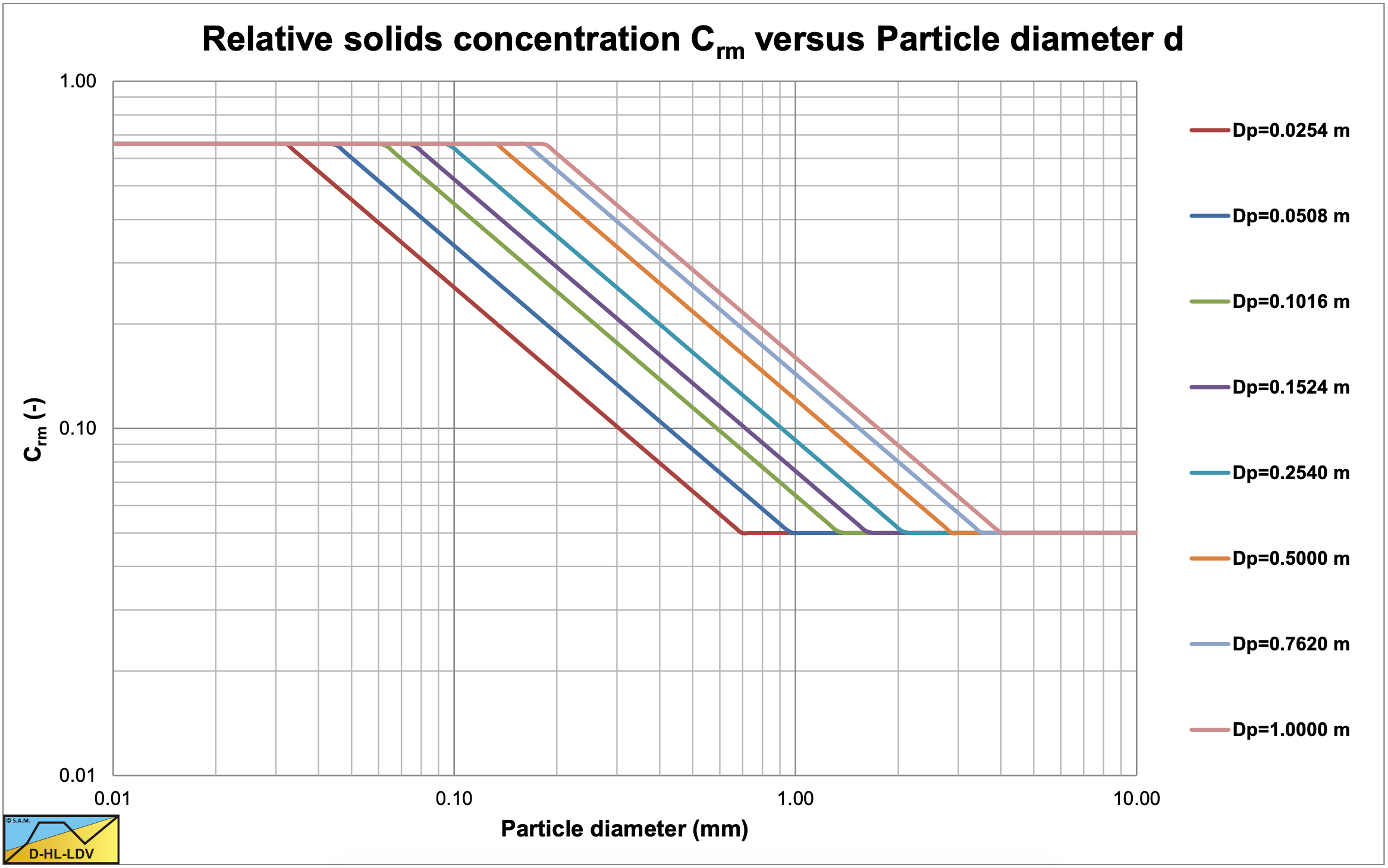

The volumetric transport concentration at this maximum Limit of Stationary Deposit Velocity can be estimated by, with d in mm and Dp in m (for Crm in the range 0.05-0.66):

\[\ \mathrm{C}_{\mathrm{rm}}=\mathrm{C}_{\mathrm{vr}, \mathrm{max}}=\mathrm{0.16} \cdot \mathrm{D}_{\mathrm{p}}^{0.40} \cdot \mathrm{d}^{-0.84} \cdot\left(\frac{\mathrm{R}_{\mathrm{sd}}}{1.65}\right)^{-0.17}\]

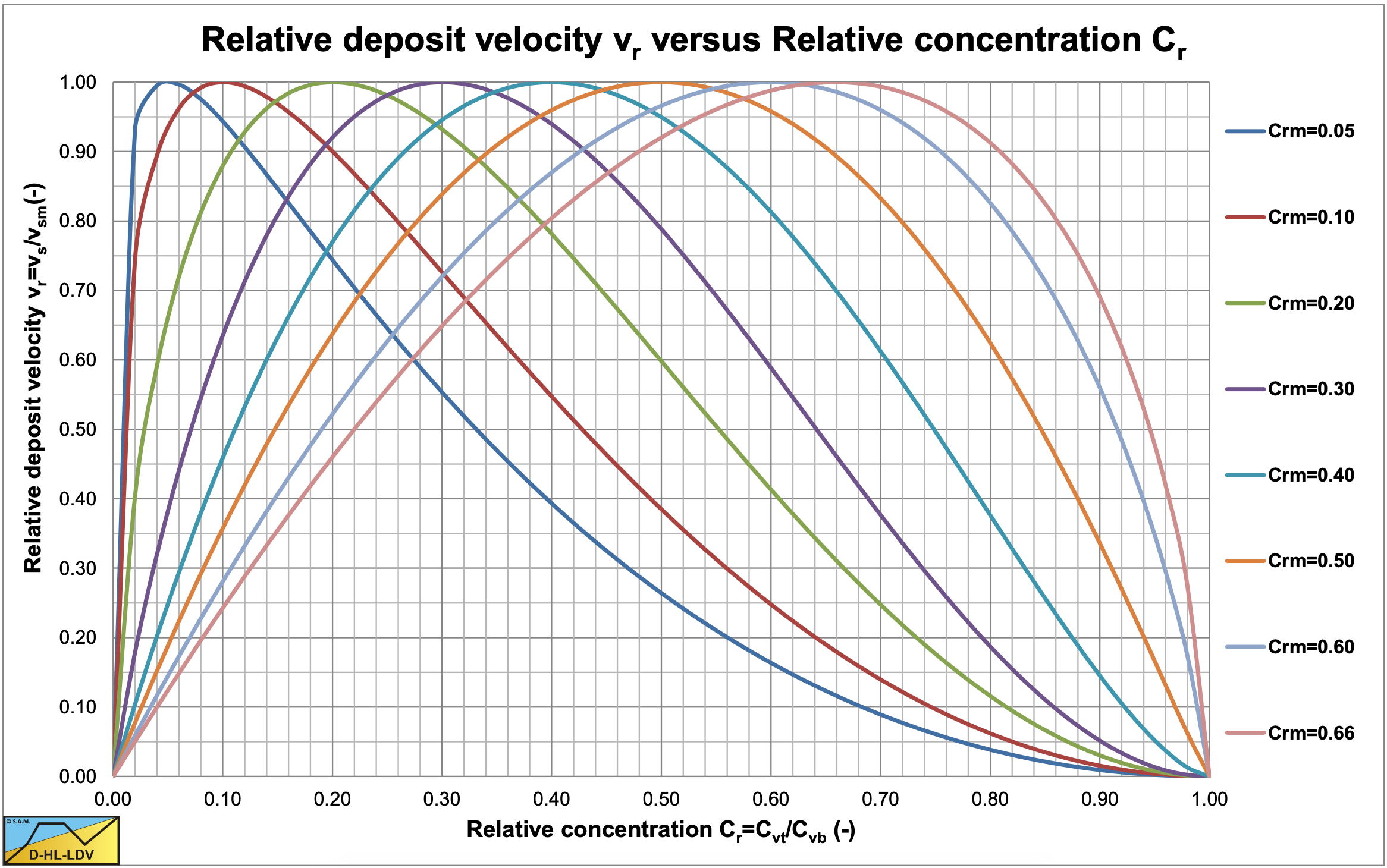

For other volumetric transport concentrations, the Limit of Stationary Deposit Velocity vs can be estimated by:

\[\ \begin{array}{left}\frac{\mathrm{v}_{\mathrm{s}}}{\mathrm{v}_{\mathrm{sm}}}=\mathrm{6.75} \cdot \mathrm{C}_{\mathrm{vr}}^{\alpha} \cdot\left(1-\mathrm{C}_{\mathrm{vr}}^{\alpha}\right)^{2} \quad\text{ if }\quad \mathrm{C}_{\mathrm{vr}, \max } \leq \mathrm{0.33}\\

\frac{\mathrm{v}_{\mathrm{s}}}{\mathrm{v}_{\mathrm{sm}}}=\mathrm{6.75} \cdot\left(\mathrm{1}-\mathrm{C}_{\mathrm{vr}}\right)^{2 \cdot \beta} \cdot\left(1-\left(1-\mathrm{C}_{\mathrm{vr}}\right)^{\beta}\right) \quad\text{ if }\quad \mathrm{C}_{\mathrm{vr}, \max }>0.33\\

\text{ With: } \quad \alpha=\frac{\ln (0.333)}{\ln \left(\mathrm{C}_{\mathrm{vr}, \max }\right)} \quad\text{ and }\quad \beta=\frac{\ln (0.666)}{\ln \left(1-\mathrm{C}_{\mathrm{vr}, \max }\right)}\end{array}\]

The asymptotic normalized excess hydraulic gradient for very high line speeds can be determined by:

\[\ \zeta_{\infty}=\mathrm{0 . 5} \cdot \mathrm{C}_{\mathrm{vr}} \cdot\left(1+\mathrm{C}_{\mathrm{vr}}^{0.66}\right)\]

For lower line speeds the normalized excess hydraulic gradient can now be determined by:

\[\ \begin{array}{left}\zeta=\zeta_{\infty}+\left(1-\zeta_{\infty}\right) \cdot\left(1+\mathrm{v}_{\mathrm{r}}\right)^{-\mathrm{q}}\\

\mathrm{q}=3.6-\mathrm{5} .2 \cdot \mathrm{C}_{\mathrm{vr}} \cdot\left(1-\mathrm{C}_{\mathrm{vr}}\right) \quad\text{ if }\quad \mathrm{C}_{\mathrm{vr}} \geq \mathrm{C}_{\mathrm{vr}, \max }\end{array}\]

or

\[\ \mathrm{q}=\left(3.6-5.2 \cdot \mathrm{C}_{\mathrm{vr}, \max } \cdot\left(1-\mathrm{C}_{\mathrm{vr}, \max }\right)\right) \cdot \frac{\mathrm{C}_{\mathrm{vr}, \max }}{\mathrm{C}_{\mathrm{vr}}} \quad\text{ if }\quad \mathrm{C}_{\mathrm{vr}}<\mathrm{C}_{\mathrm{vr}, \mathrm{max}}\]

Figure 6.20-14 shows the maximum Durand Froude number as a function of the particle diameter (in mm) and the pipe diameter (in m). Figure 6.20-15 shows how the concentration where the maximum LSDV occurs depends on the particle diameter (in mm) and the pipe diameter (in m). Figure 6.20-16 shows how the LSDV depends on the relative concentration and the concentration where the maximum LSDV occurs. Figure 6.20-17 shows a resulting LSDV curve.

Later a shear layer or sheet flow layer was incorporated. If the sharp interface between a bed and the carrier liquid above the bed is replaced by a shear layer, the driving force at the interface is no longer dependent on the roughness of the bed. Therefore the particle size does not influence the maximum LSDV. The Durand Froude number can be determined with the following equation in this case:

\[\ \mathrm{F}_{\mathrm{L}}=\frac{\mathrm{v}_{\mathrm{s m}}}{\sqrt{\mathrm{2} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{D}_{\mathrm{p}}}}=\left(\frac{\mathrm{0.} \mathrm{0} \mathrm{1} \mathrm{8}}{\lambda_{\mathrm{l}}}\right)^{0 . \mathrm{1 3}}\]

The smaller of the two LSDV approximations should be chosen. The above equation is derived fro a specific bed concentration and sliding friction coefficient. Other conditions may give a slightly different equation.

With these equations, Figure 6.20-18 is reconstructed.

Of course the curves cannot exist inside the stationary bed region. However here the curves are shown as given by Wilson. This comment is also valid for the next figure.

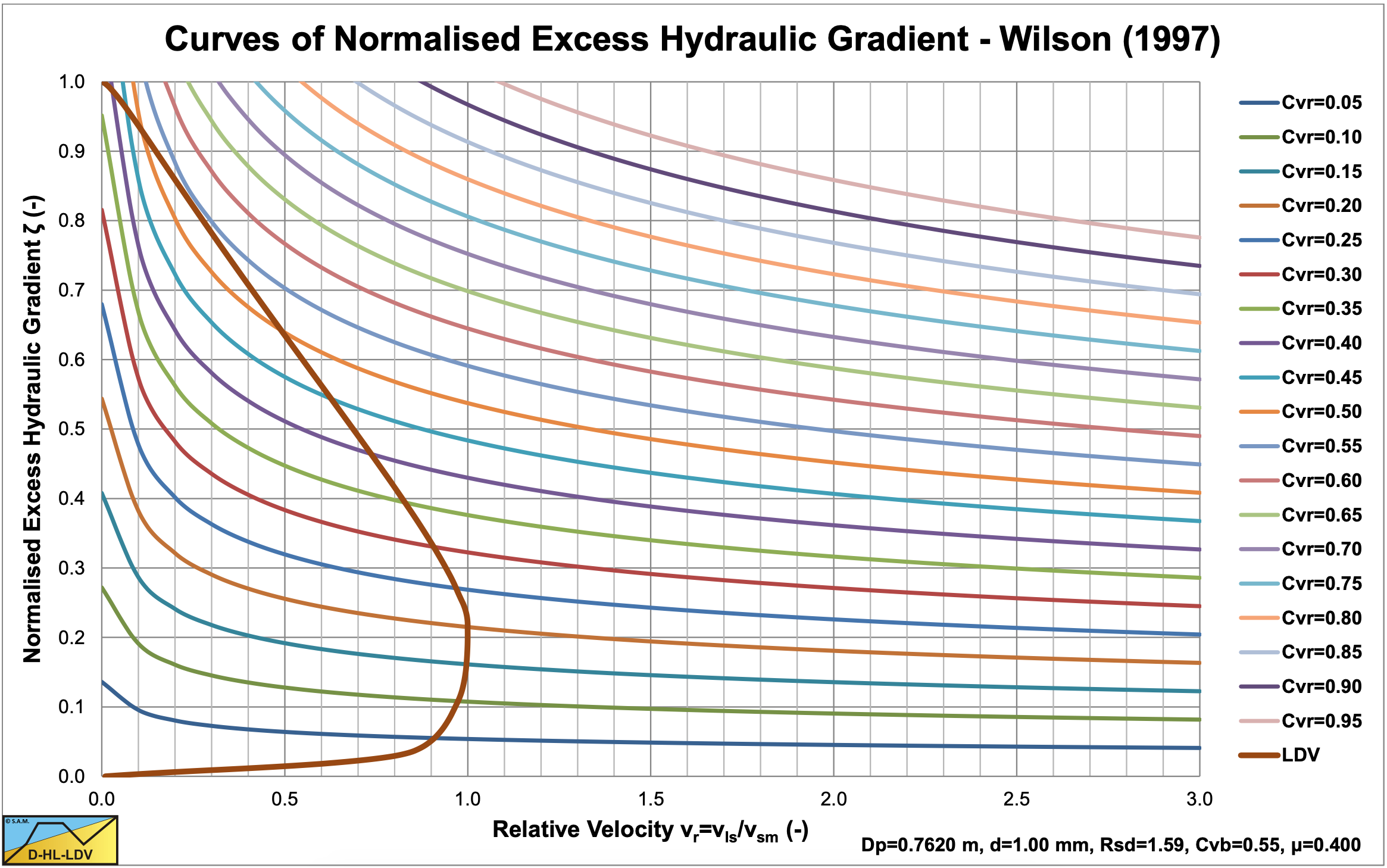

6.20.1.7 The Fit Functions of Wilson et al. (1997)

The relative excess hydraulic gradient can be approximated by (for a sliding friction coefficient of 0.4 and 0.44):

\[\ \begin{array}{left} \mathrm{E}_{\mathrm{r h g}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{t}}}=\left(\frac{\mathrm{0 . 5 5} \cdot \mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25}=\mathrm{0 . 8 6 1} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{4} \cdot \mathrm{v}_{\mathrm{s m}}}{\mathrm{3} \cdot \mathrm{v}_{\mathrm{l s}}}\right)^{0.25} \quad\text{ for }\mu_{\mathrm{s f}}=\mathrm{0 . 4 0}\\

\mathrm{E}_{\mathrm{r h g}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v t}}}=\left(\frac{\mathrm{0 . 5 5 \cdot v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25}=\mathrm{0 . 8 6 1} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25}=\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25} \quad\text{ for }\mu_{\mathrm{sf}}=\mathrm{0 . 4 4}\end{array}\]

In the case where the line speed equals the maximum Limit of Stationary Deposit Velocity vsm, this gives:

\[\ \mathrm{E}_{\mathrm{rhg}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vt}}}=2 \cdot \mu_{\mathrm{sf}} \cdot\left(\frac{4}{3}\right)^{0.25} \quad\text{ or }\quad \mathrm{E}_{\mathrm{rhg}}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{vt}}}=2 \cdot \mu_{\mathrm{sf}}\]

This gives for the normalized excess hydraulic gradient at this line speed:

\[\ \zeta=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{i}_{\mathrm{plug}}}=\frac{\mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v t}}}{\mathrm{2} \cdot \mathrm{\mu}_{\mathrm{s f}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{b}}}=\frac{\mathrm{C}_{\mathrm{v t}}}{\mathrm{C}_{\mathrm{v b}}} \cdot\left(\frac{4}{\mathrm{3}}\right)^{\mathrm{0 . 2 5}} \quad\text{ or }\quad \zeta=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{i}_{\mathrm{p l u g}}}=\frac{\mathrm{C}_{\mathrm{v} \mathrm{t}}}{\mathrm{C}_{\mathrm{v} \mathrm{b}}}\]

Figure 6.20-19 shows the resulting normalized excess hydraulic gradient curves.

6.20.1.8 The Stratification Ratio

The Wilson et al. (1997) model is based on a 100% stationary or sliding bed giving 100% stratification. However at a certain velocity of the liquid above the bed erosion may occur, related to the Shields parameter as described in chapter 5. It is also possible that a shear layer or sheet flow occurs at the top of the bed. Erosion will reduce the bed thickness while a shear layer or sheet flow will influence the Moody friction coefficient at the top of the bed. Whatever the mechanism may be, the bed will dissolve with increasing line speed and transit to (pseudo) homogeneous flow at (very) high line speeds. In order to take this into account, Wilson et al. (1997) defined a stratification ratio, being the amount of particles in the bed (in contact) divided by the total amount of particles in a cross section of the pipe.

\[\ \mathrm{R}=\frac{\mathrm{C}_{\mathrm{vc}}}{\mathrm{C}_{\mathrm{v s}}}\]

If all the available particles are in the bed the stratification ratio is 1 or 100%. If all the available particles are in suspension the stratification ratio is 0 or 0%. The amount of particles in suspension, being part of the homogeneous, equivalent liquid model, flow equals 1 minus the stratification ratio. To determine the total hydraulic gradient Wilson et al. (1997) adds the stratification ratio times the bed resistance and 1 minus the stratification ratio times the ELM resistance according to:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{R} \cdot \mathrm{i}_{\mathrm{b e d}}+(\mathrm{1}-\mathrm{R}) \cdot \mathrm{i}_{\mathrm{h o m}}\]

Basically this means that the superposition principle is applied on a mix of the sliding bed regime and the homogeneous regime. This implies that the behavior of both processes is linear, which does not have to be the case. However, by determining the formulation of the stratification ratio experimentally, resulting in an empirical equation, this will correct itself. This empirical equation is determined based on the hydraulic gradient and not based on the real stratification ratio.

6.20.1.9 Suspension in the Upper Layer

The basic Wilson et al. (1992) two layer model considers a fixed or sliding bed with water above the bed. So we have a bed layer and a water layer. Wilson et al. (1990) defined a threshold velocity at which particles start suspending. This threshold velocity is defined as:

\[\ \mathrm{v}_{\mathrm{u}}=\mathrm{v}_{\mathrm{t}} \cdot \sqrt{\frac{\mathrm{8}}{\lambda_{\mathrm{l}}}}{ \cdot \mathrm{e}^{\frac{45 \cdot \mathrm{d}}{\mathrm{D}_{\mathrm{p}}}}} \quad\text{ or }\quad \mathrm{u}_{*}=\sqrt{\frac{\lambda_{\mathrm{l}}}{\mathrm{8}}}{ \cdot \mathrm{v}_{\mathrm{u}}}=\mathrm{v}_{\mathrm{t}} \cdot \mathrm{e}^{\frac{4 \mathrm{5} \cdot \mathrm{d}}{\mathrm{D_p}}}\]

\[\ \mathrm{R}=\left(\frac{\mathrm{v}_{\mathrm{u}}}{\mathrm{v}_{\mathrm{ls}}}\right)^{\mathrm{M}}\]

So when the line speed vls equals the threshold velocity vu, the stratification ratio R equals 1, meaning that 100% of the particles is in the bed. As the line speed increases, the stratification ratio decreases. The power M has a value of 1.7 for very narrow graded sands or gravels, uniform sands or gravels. The more graded a sand or gravel, the smaller the power M with a minimum of 0.25. This approach forms the basis of the heterogeneous model of Wilson et al. (1992). The amount of solids in suspension is now 1-Cvc/Cvs=(1-R).

By determining the amount of solids in suspension and adjusting the fluid density and viscosity and the amount of solids in the bed, the two layer model can be applied for small particles. The Thomas (1965) equation can be used to adjust the viscosity of the liquid/solid mixture. This explains decrease of the LSDV with decreasing particle diameter for particles smaller than about d=0.7 mm. It also explains for the increase of the spatial concentration where the maximum LSDV occurs with decreasing particle diameter. The delivered concentration is in this case Cvt=(1-R)·Cvs. For other solids densities this behavior may be different, since large particles probably have a different influence on the viscosity.

6.20.1.10 Conclusions & Discussion

The Wilson et al. (1992) model forms a solid base for 2 layer and 3 layer models. The model is based on the force equilibrium on the bed and is capable of determining the Limit of Stationary Deposit Velocity curve for the start of sliding of the bed. The model also gives the bed velocity for line speeds above the Limit of Stationary Deposit Velocity. Although the model is based on constant spatial volumetric concentration curves, based on the bed velocity the delivered volumetric concentration can be determined. Connecting points with constant delivered volumetric concentration, enables to construct constant delivered volumetric concentration curves as used in practice. The model however still has a number of shortcomings. First of all, the Darcy-Weisbach friction factor on the bed is assumed to be constant, not depending on the velocity above the bed (Wilson uses a factor 2 or 2.75). Since above a certain line speed the top layer of the bed will be sheet flow, the Darcy-Weisbach friction factor will increase with increasing line speed. Sheet flow also implies higher velocities of the particles in the sheet flow layer, resulting in higher delivered volumetric concentrations. The model however assumes a solid sliding bed without any particles above the bed, either in suspension or in a sheet flow layer. A second shortcoming is the hydrostatic normal stress between the bed and the wall. This assumption in the model also neglects the presence of particles in suspension or in a sheet flow layer apart from the fact that this assumption is questionable in the first place for beds occupying more than 50% of the pipe. The hydrostatic approach implies an upwards component of the normal stress between the bed and the pipe wall in this case, which normally will not occur.

With regard to the fit functions of Wilson et al. (1992) and (1997), in both cases the fit lines intersect with the Limit of Stationary Deposit Velocity curve, which is not physically possible, since the delivered volumetric concentration is zero on these lines. At line speeds much higher than the Limit of Stationary Deposit Velocity, the fit curves may however be correct.

Since Wilson et al. (1992) and (1997) developed the model in a time period without sophisticated computers and software as we have today, it must have been a tedious job to create his graphs. Nowadays a relatively simple Excel sheet can do the job, resulting in the graphs as shown in this chapter.

Later researchers improved the model, like Doron et al. (1987) a two layer model, Doron & Barnea (1993) a three layer model and Matousek (1997) two and three layer models.

6.20.2 The Wilson-GIW (1992) Model for Heterogeneous Transport

6.20.2.1 The Full Model

Assuming that 50% of the solids is moving in the bed by granular contact at a line speed of v50, and assuming a friction coefficient μsf between the particles and the pipe wall, the friction force in a pipe with length ΔL is:

\[\ \mathrm{F}_{\mathrm{s f}}=\frac{\mu_{\mathrm{s f}}}{2} \cdot \mathrm{A}_{\mathrm{p}} \cdot \Delta \mathrm{L} \cdot \mathrm{C}_{\mathrm{v}} \cdot\left(\rho_{\mathrm{s}}-\rho_{\mathrm{l}}\right) \cdot \mathrm{g}\]

This gives an excess pressure due to the solids of:

\[\ \Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}=\frac{\mathrm{F}_{\mathrm{s f}}}{\mathrm{A}_{\mathrm{p}}}=\frac{\mu_{\mathrm{s f}}}{2} \cdot \Delta \mathrm{L} \cdot \mathrm{C}_{\mathrm{v}} \cdot\left(\rho_{\mathrm{s}}-\rho_{\mathrm{l}}\right) \cdot \mathrm{g}\]

In terms of the hydraulic gradient this can be written as:

\[\ \mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}=\frac{\Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}}{\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\frac{\mu_{\mathrm{s f}}}{\mathrm{2}} \cdot \mathrm{C}_{\mathrm{v}} \cdot \frac{\left(\rho_{\mathrm{s}}-\rho_{\mathrm{l}}\right)}{\rho_{\mathrm{l}}}=\frac{\mu_{\mathrm{s f}}}{\mathrm{2}} \cdot \mathrm{C}_{\mathrm{v}} \cdot \mathrm{R}_{\mathrm{s d}}\]

Wilson (1997) has defined a stratification ratio or relative solids effect, which tells which fraction of the particles, is in suspension and which part is in the fixed or moving bed, supported by granular contact. Wilson (1997) gives the following general equation for the head losses in hydraulic transport, where μsf equals the friction factor of a sliding bed, which he has determined to be μsf=0.44. For the 50% case this gives:

\[\ \mathrm{E}_{\mathrm{r h g}}=\mathrm{R}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{C}_{\mathrm{v}}}=\frac{\Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}}{\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v}}}=\frac{\mu_{\mathrm{s f}}}{\mathrm{2}} \cdot\left(\frac{\mathrm{v}_{\mathrm{5 0}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{M}}\]

When the line speed vls equals the v50, the stratification ratio is 0.22 or half the friction coefficient μsf. This can be written in terms of pressures instead of hydraulic gradient as:

\[\ \Delta \mathrm{p}_{\mathrm{m}}=\Delta \mathrm{p}_{\mathrm{l}}+\frac{\mu_{\mathrm{s f}}}{\mathrm{2}} \cdot \rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \mathrm{\Delta} \mathrm{L} \cdot\left(\frac{\mathrm{v}_{\mathrm{5 0}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{M}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v}}\]

This equation can be written in the more generic form, matching the notations of the other theories:

\[\ \Delta \mathrm{p}_{\mathrm{m}}=\Delta \mathrm{p}_{\mathrm{l}} \cdot\left(\mathrm{1}+\frac{\boldsymbol{\mu}_{\mathrm{s f}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{D}_{\mathrm{p}}}{\lambda_{\mathrm{l}}} \cdot\left(\mathrm{v}_{\mathrm{5} 0}\right)^{\mathrm{M}} \cdot\left(\frac{\mathrm{1}}{\mathrm{v}_{\mathrm{ls}}}\right)^{\mathrm{2}+\mathrm{M}} \cdot \mathrm{C}_{\mathrm{v}}\right)\]

For the line speed, where 50% of the particles is in granular contact, v50, Wilson gives the following equation:

\[\ \mathrm{v}_{50}=\mathrm{w}_{50} \cdot \sqrt{\frac{\mathrm{8}}{\lambda_{\mathrm{l}}}} \cdot \cosh \left(\frac{\mathrm{6 0} \cdot \mathrm{d}_{50}}{\mathrm{D}_{\mathrm{p}}}\right)\]

When the power M equals 1, this equation has the same form as the equation of Durand & Condolios, Gibert, Fuhrboter, Jufin Lopatin and Newitt et al. The power M depends on the grading of the sand and can be determined by:

\[\ \mathrm{M}=\left(0.25+13 \cdot \sigma^{2}\right)^{-1 / 2}\]

The variance σ of the PSD (Particle Size Distribution), can be determined by some ratio between the v50 and the v85:

\[\ \sigma=\log \left(\frac{\mathrm{v}_{85}}{\mathrm{v}_{50}}\right)=\log \left(\frac{\mathrm{w}_{85} \cdot \sqrt{\frac{8}{\lambda_{\mathrm{l}}}} \cdot \cosh \left(\frac{60 \cdot \mathrm{d}_{85}}{\mathrm{D}_{\mathrm{p}}}\right)}{\mathrm{w}_{50} \cdot \sqrt{\frac{\mathrm{8}}{\lambda_{\mathrm{l}}}}{ \cdot \cosh \left(\frac{60 \cdot \mathrm{d}_{50}}{\mathrm{D}_{\mathrm{p}}}\right)}}\right)\]

The terminal settling velocity related parameter w, the particle associated velocity, can be determined by:

\[\ \mathrm{w}=\mathrm{0.9} \cdot \mathrm{v}_{\mathrm{t}}+\mathrm{2 . 7} \cdot\left(\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3}\]

It seems this equation mixes the homogeneous and heterogeneous regimes. For very small particles the second term gives a constant particle associated velocity, which matches homogeneous behavior at operational line speeds. Since the homogeneous behavior does not depend on the particle size, this gives a constant or asymptotic particle associated velocity.

6.20.2.2 The Simplified Wilson Model

The model of Wilson can be simplified with some fit functions, according to:

\[\ \mathrm{v}_{50} \approx 3.93 \cdot\left(1000 \cdot \mathrm{d}_{50}\right)^{0.35} \cdot\left(\frac{\mathrm{R}_{\mathrm{sd}}}{1.65}\right)^{0.45} \cdot\left(\frac{v_{\mathrm{l}, \text { actual }}}{v_{\mathrm{w}, 20}}\right)^{-0.25}\]

In which the particle diameter d50 is in m and the resulting v50 in m/s. The third term on the right had side is the relative viscosity, the actual liquid viscosity divided by the viscosity of water at 20 degrees Centigrade. In normal dredging practice this term is about unity and can be neglected. The factor 1.65 is based on sand in pure water.

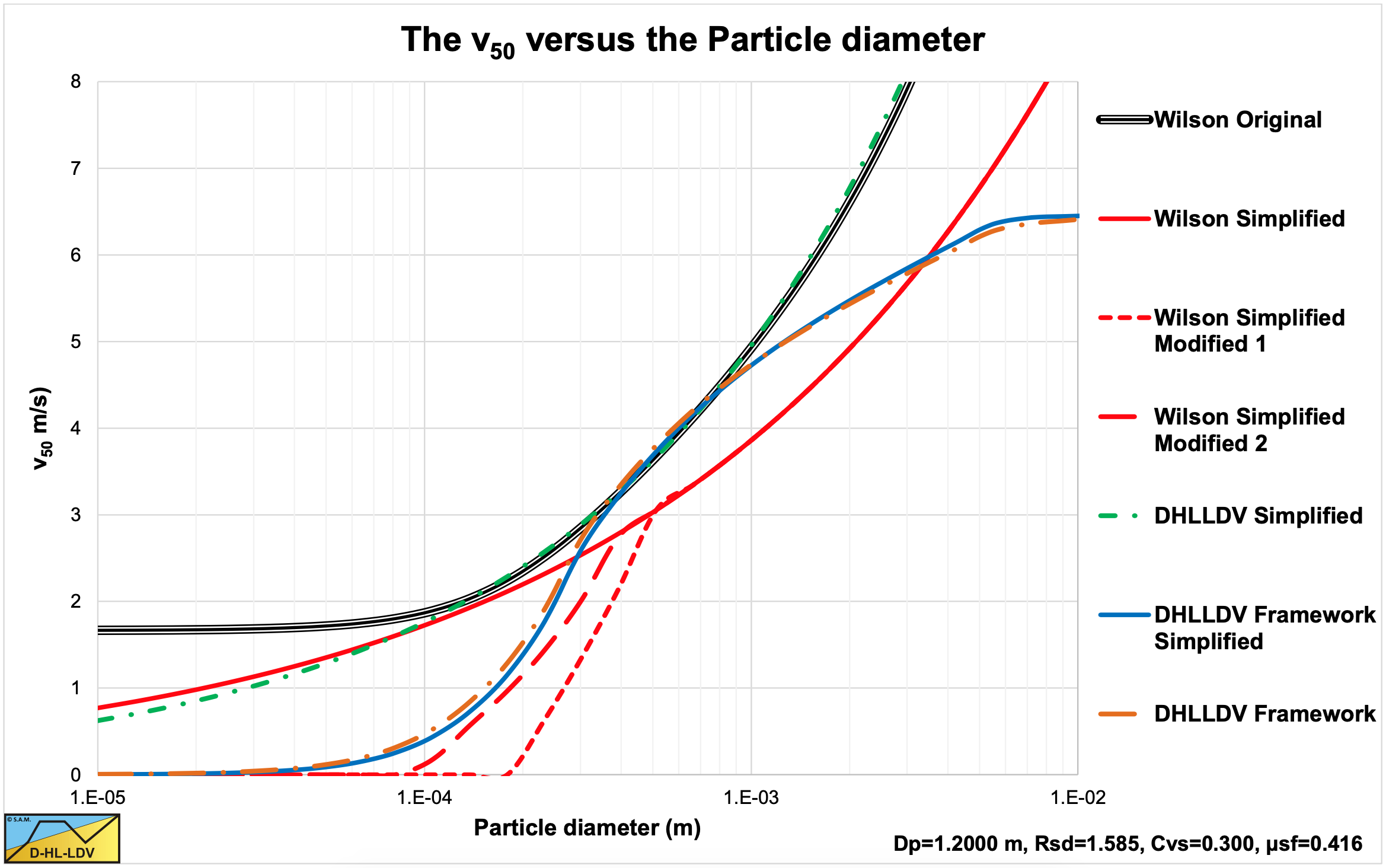

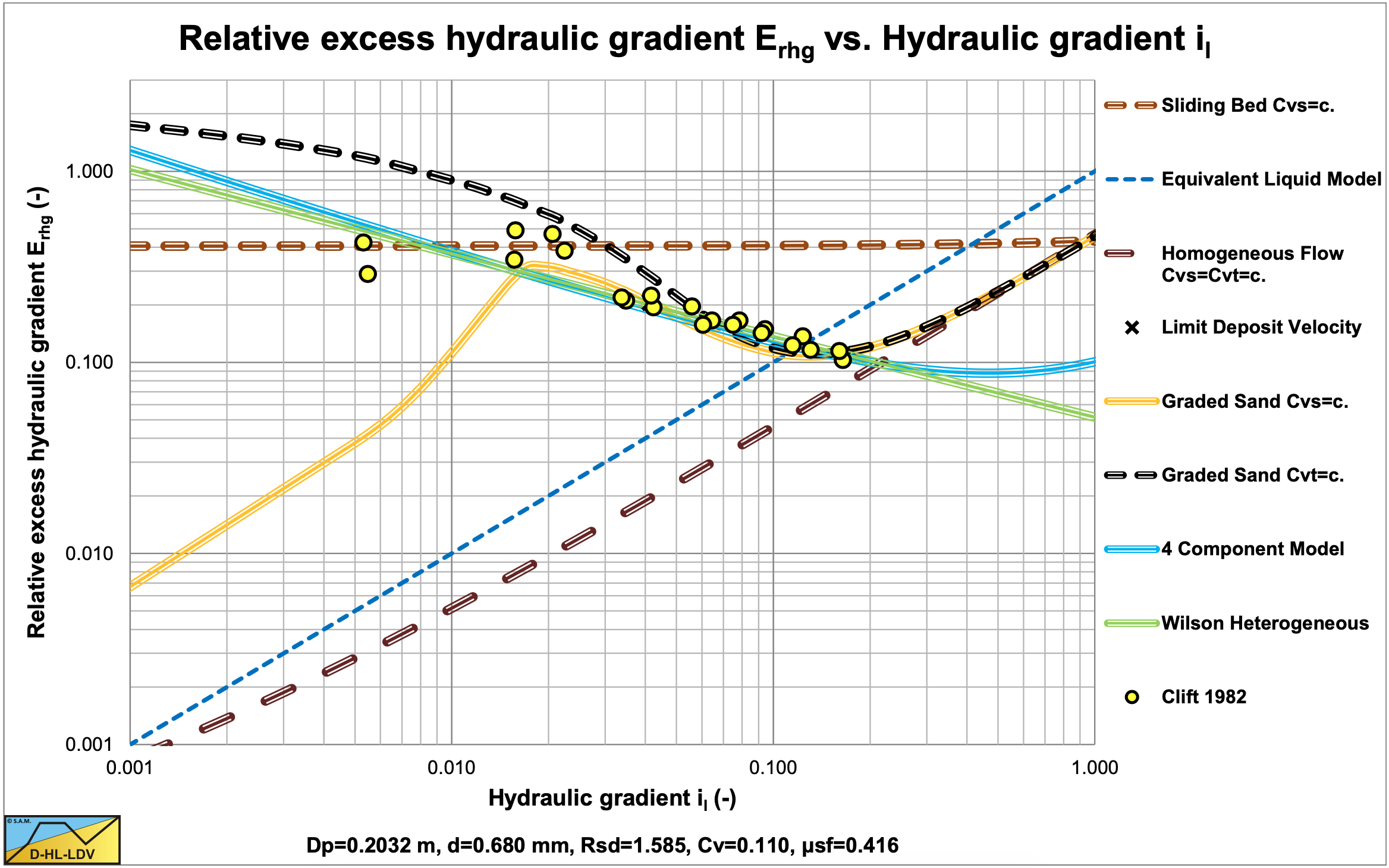

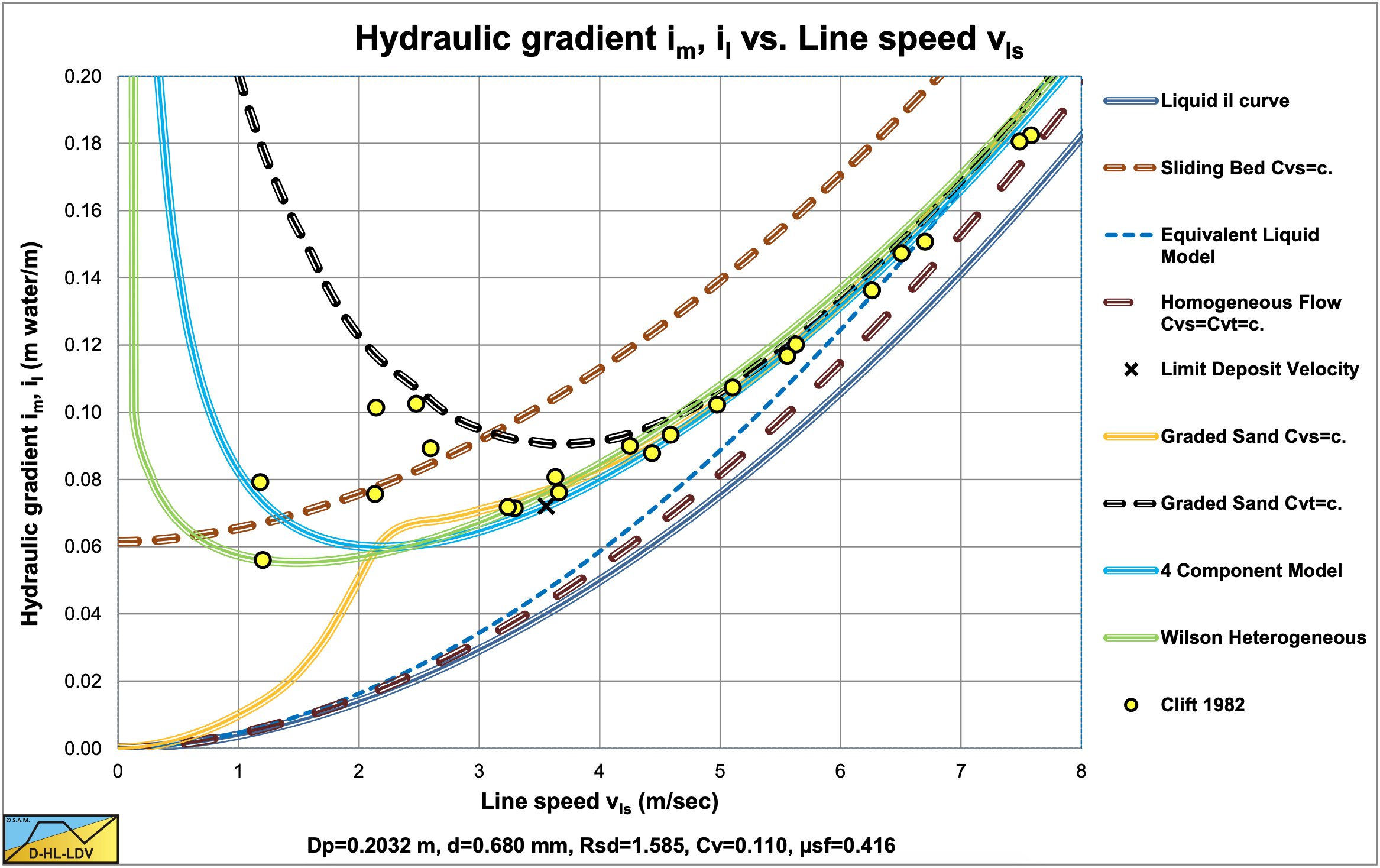

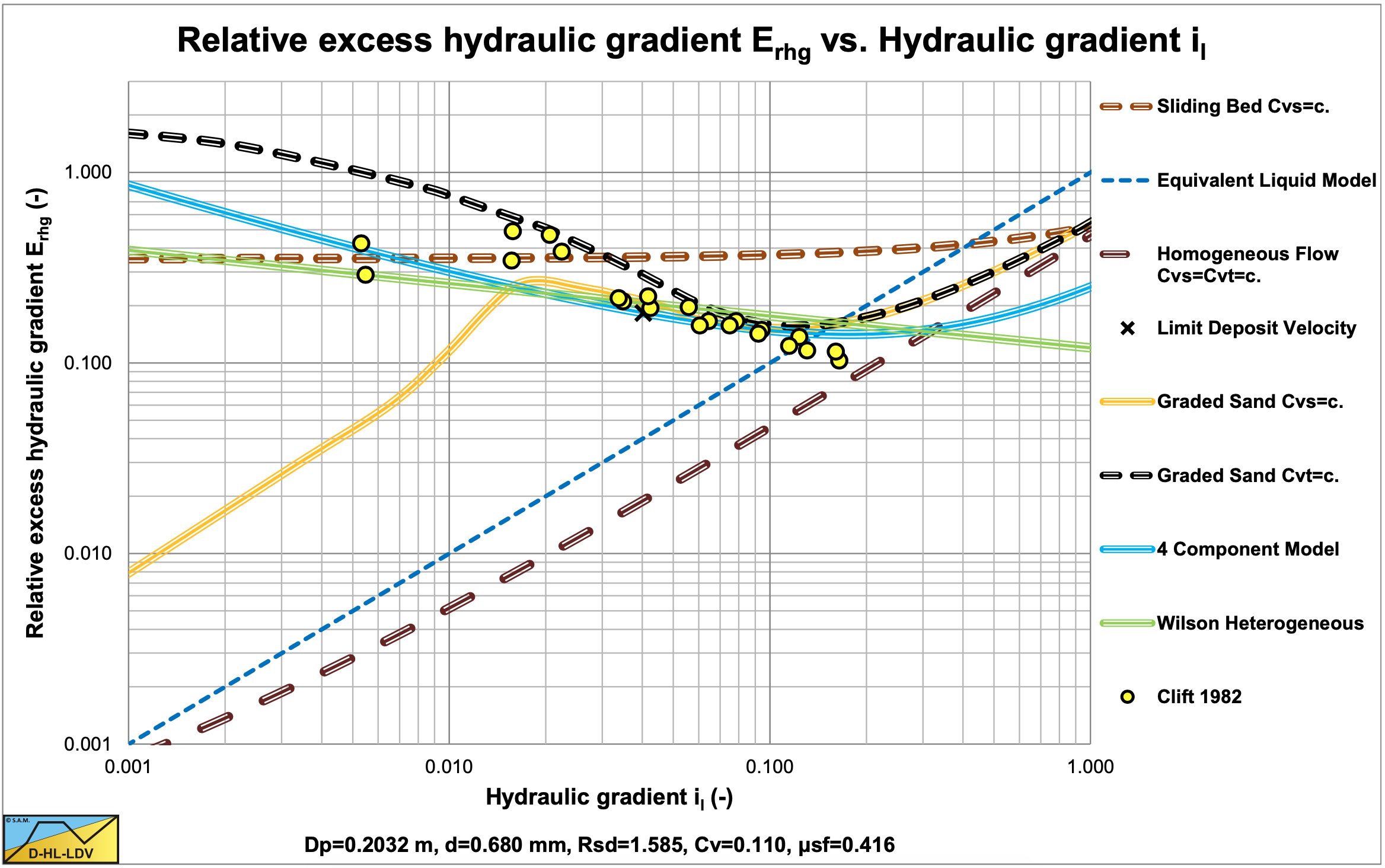

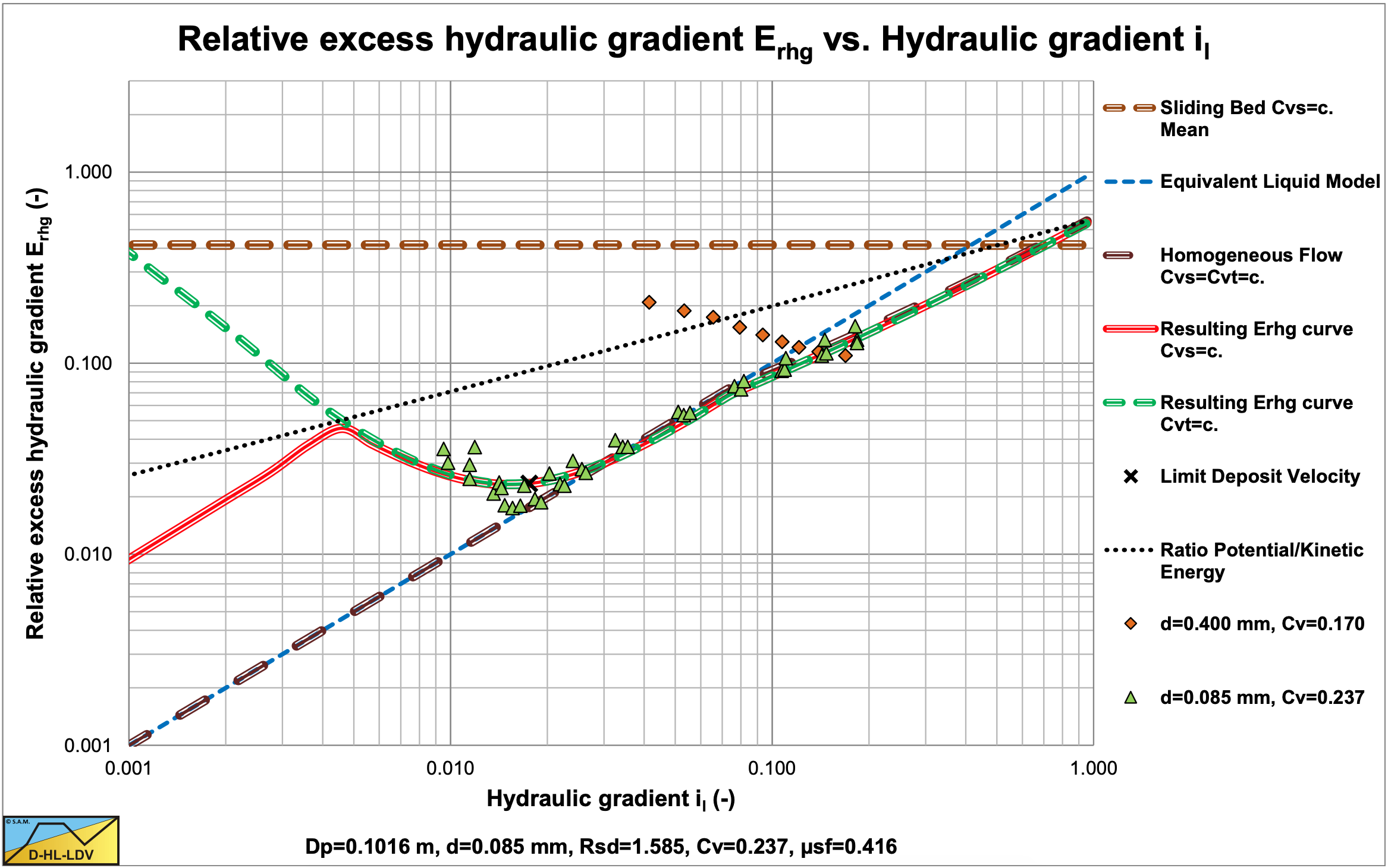

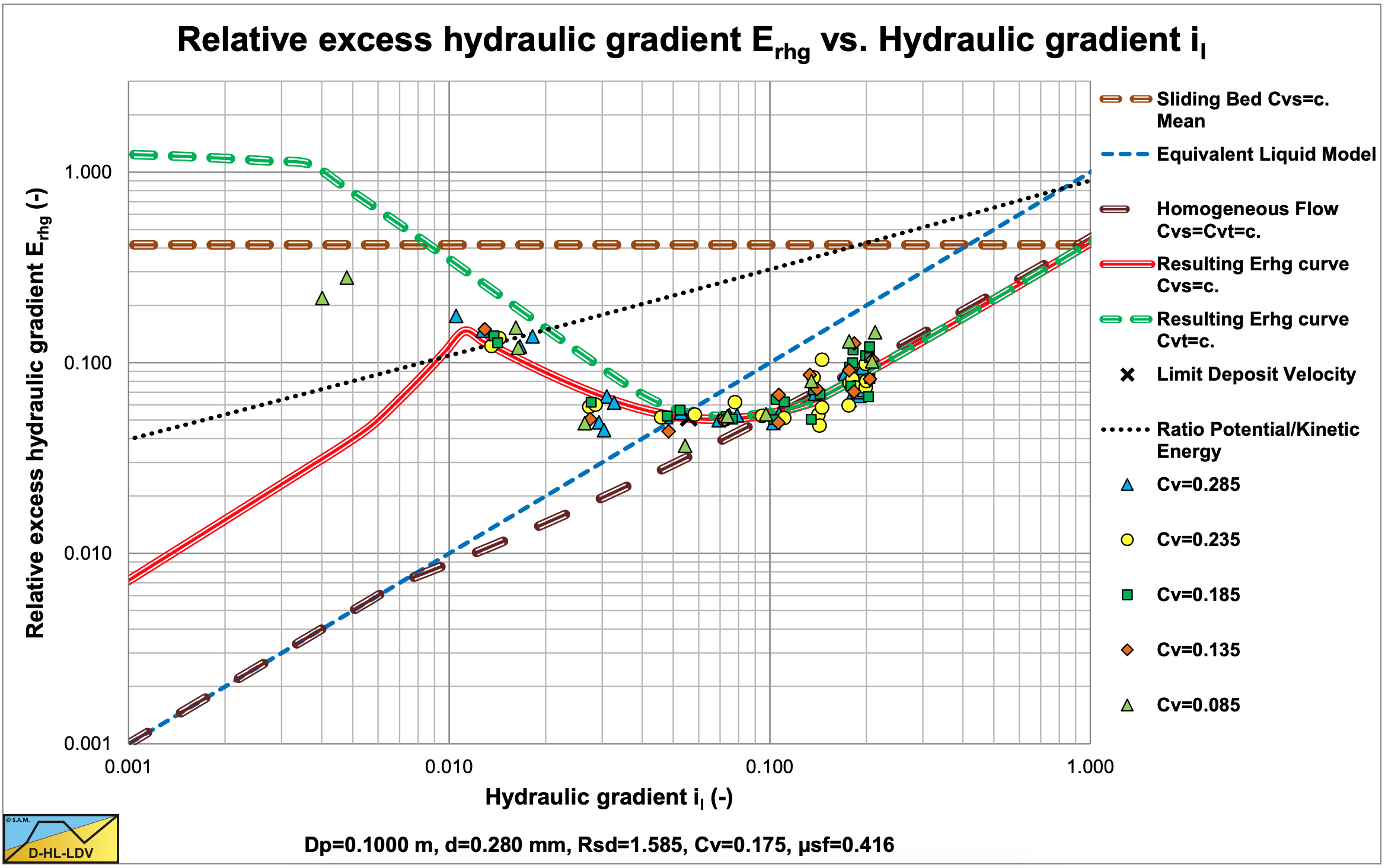

In Figure 6.20-20, Figure 6.20-21 and Figure 6.20-22, the DHLLDV Framework is used for comparison.

The exponent M is given by the approximation:

\[\ \mathrm{M} \approx\left(\ln \left(\frac{\mathrm{d}_{85}}{\mathrm{d}_{50}}\right)\right)^{-1}\]

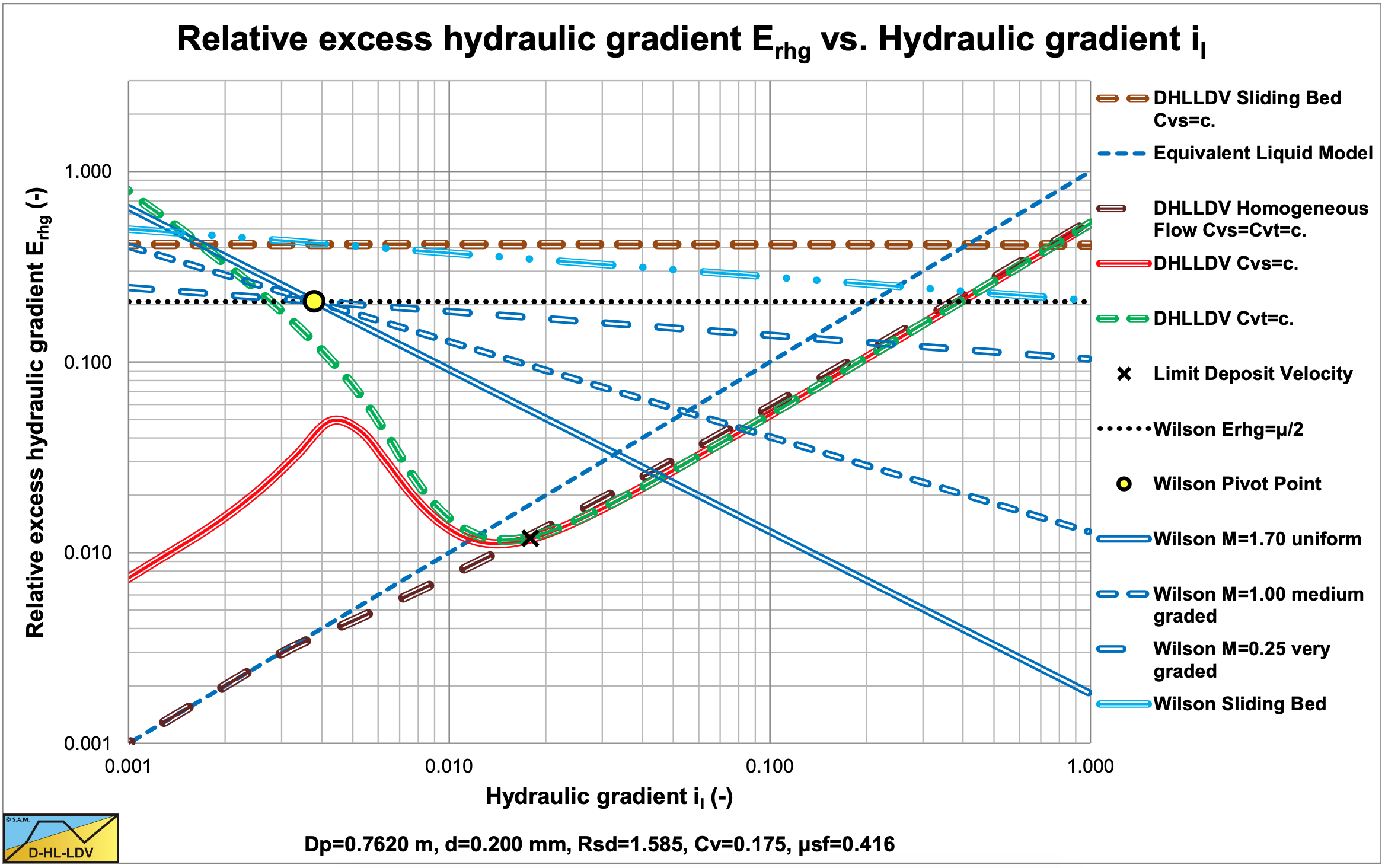

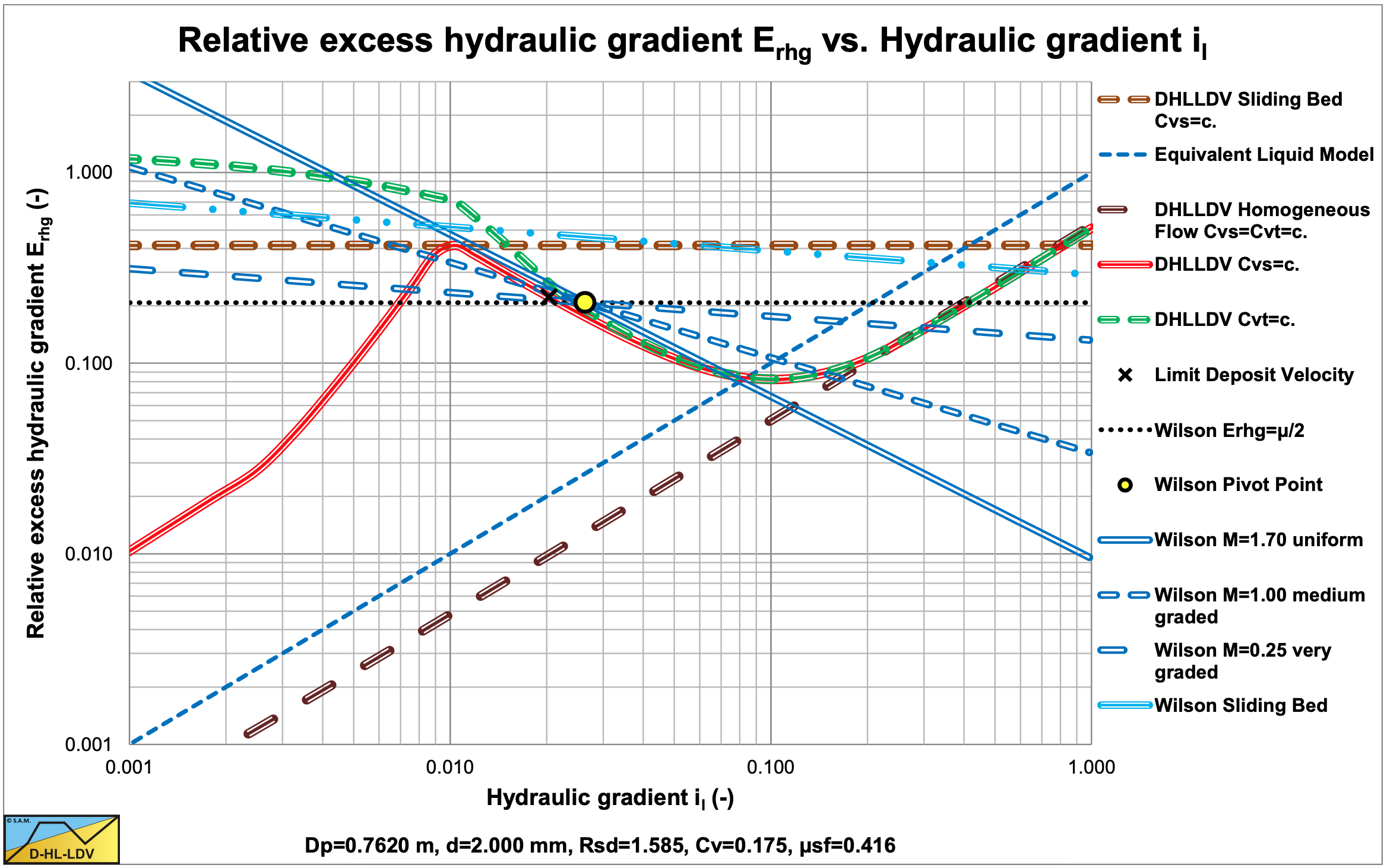

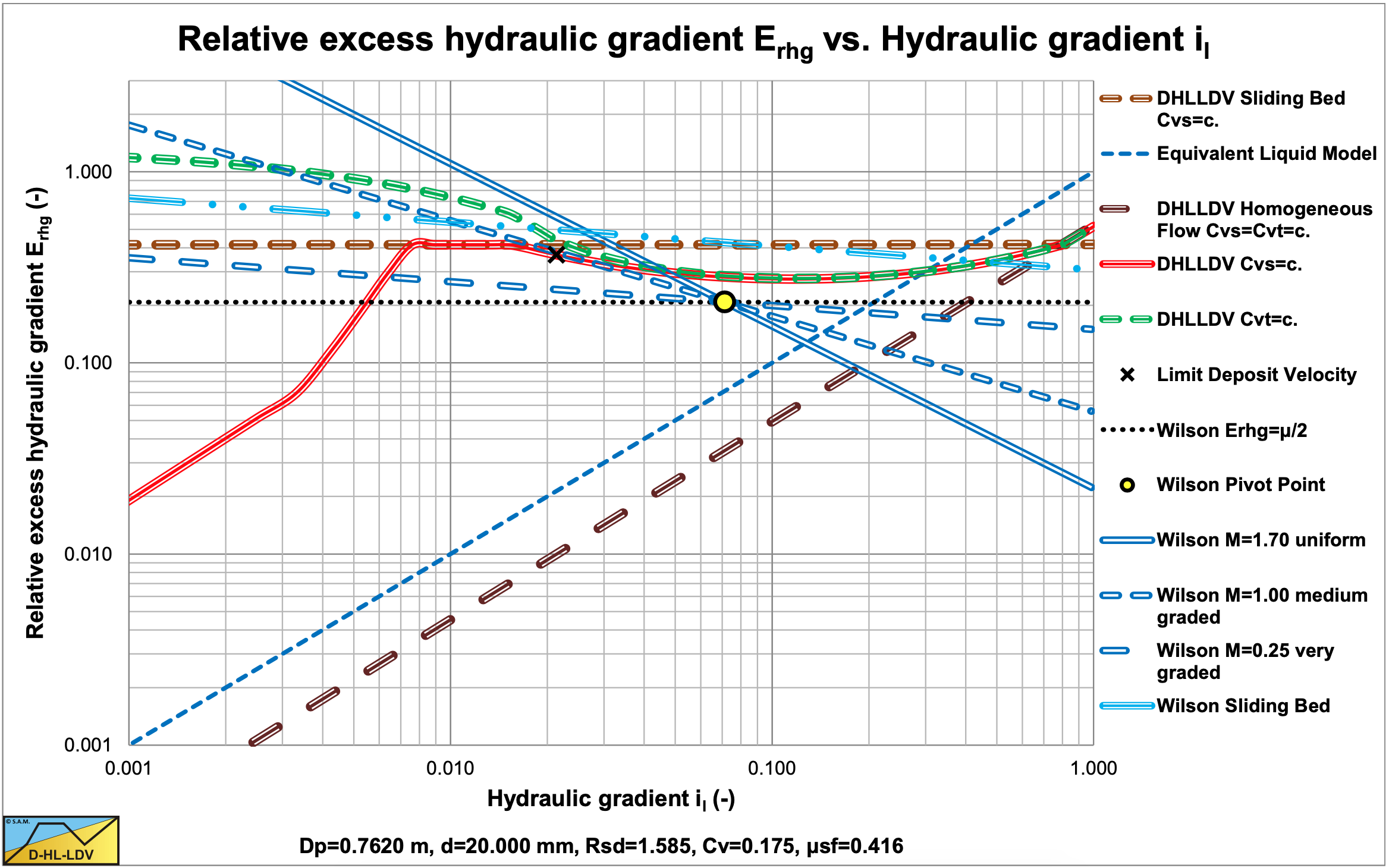

Figure 6.20-21 shows the Wilson et al. (1992) model in Erhg(il) coordinates. The black dotted line is the Erhg=μsf/2 line. The yellow circle the point with vls=v50. The heterogeneous Wilson lines have powers of M=1.7, 1.0 & 0.25. So heterogeneous lines always cross the yellow circle, the v50 point, and are rotated around this point depending on the power M. The higher the power M, the steeper the line in this graph.

6.20.2.3 Generic Equation

Based on equation (6.20-53) and equation (6.20-58) and the assumption M=1 for d85/d50=2.72 and assuming the liquid is water of 20 degrees Centigrade and the solids are sand (quarts), an equation is derived to compare Wilson with the other theories:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}} \cdot\left(\mathrm{1}+\frac{\mu_{\mathrm{s f}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{D}_{\mathrm{p}}}{\lambda_{\mathrm{l}}} \cdot\left(\mathrm{v}_{\mathrm{5} 0}\right)^{\mathrm{M}} \cdot\left(\frac{\mathrm{1}}{\mathrm{v}_{\mathrm{ls}}}\right)^{2+\mathrm{M}} \cdot \mathrm{C}_{\mathrm{v}}\right)\]

For the line speed v50:

\[\ \mathrm{v}_{\mathrm{5 0}} \approx \mathrm{3.93} \cdot\left(\mathrm{1 0 0 0} \cdot \mathrm{d}_{\mathrm{5 0}}\right)^{\mathrm{0 . 3 5}}=\mathrm{4 4 . 1} \cdot\left(\mathrm{d}_{\mathrm{5 0}}\right)^{\mathrm{0 . 3 5}}\]

This gives:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}} \cdot\left(1+\frac{\mu_{\mathrm{sf}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{D}_{\mathrm{p}}}{\lambda_{\mathrm{l}}} \cdot\left(44.1 \cdot\left(\mathrm{d}_{50}\right)^{0.35}\right)^{\mathrm{M}} \cdot\left(\frac{\mathrm{1}}{\mathrm{v}_{\mathrm{l s}}}\right)^{2+\mathrm{M}} \cdot \mathrm{C}_{\mathrm{v}}\right)\]

Substituting equation (6.20-61) in equation (6.20-62) gives:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}} \cdot\left(\mathrm{1}+\mathrm{4 4 . 1}^{\mathrm{M}} \cdot \frac{\mu_{\mathrm{s f}} \cdot \mathrm{g} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{D}_{\mathrm{p}}}{\lambda_{\mathrm{l}}} \cdot\left(\mathrm{d}_{\mathrm{5} 0}\right)^{\mathrm{0 . 3 5} \cdot \mathrm{M}} \cdot\left(\frac{\mathrm{1}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{2}+\mathrm{M}} \cdot \mathrm{C}_{\mathrm{v}}\right)\]

With the friction coefficient of μsf=0.44, M=1 and some simplifications, this gives:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}} \cdot\left(\mathrm{1 + 1 9 . 4} \cdot \frac{\mathrm{g} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{D}_{\mathrm{p}}}{\lambda_{\mathrm{l}}} \cdot\left(\mathrm{d}_{50}\right)^{0.35} \cdot\left(\frac{\mathrm{1}}{\mathrm{v}_{\mathrm{l s}}}\right)^{3} \cdot \mathrm{C}_{\mathrm{v}}\right)\]

Giving each term the dimension of velocity gives:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}} \cdot\left(\mathrm{1 + 27.64} \cdot \frac{\mathrm{g} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{D}_{\mathrm{p}}}{\lambda_{\mathrm{l}}} \cdot\left(\mathrm{g} \cdot \mathrm{d}_{\mathrm{5} 0}\right)^{0.35} \cdot\left(v_{\mathrm{l}} \cdot \mathrm{g}\right)^{0.1} \cdot\left(\frac{\mathrm{1}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{3}} \cdot \mathrm{C}_{\mathrm{v}}\right)\]

Or:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}}+\mathrm{1 3 . 8 2} \cdot\left(\mathrm{g} \cdot \mathrm{d}_{\mathrm{5 0}}\right)^{\mathrm{0 . 3 5}} \cdot\left(v_{\mathrm{l}} \cdot \mathrm{g}\right)^{\mathrm{0 . 1}} \cdot \frac{\mathrm{1}}{\mathrm{v}_{\mathrm{l} \mathrm{s}}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v}}\]

The result is an equation where the excess pressure due to the solids is proportional to the pipe diameter Dp and almost proportional to the cube root of the d50 of the sand. There is no direct relation with the terminal settling velocity vt or the particle drag coefficient CD.

6.20.2.4 Analysis of the v50 Equations

The analysis in this chapter is based on the personal interpretation of the author of this book.

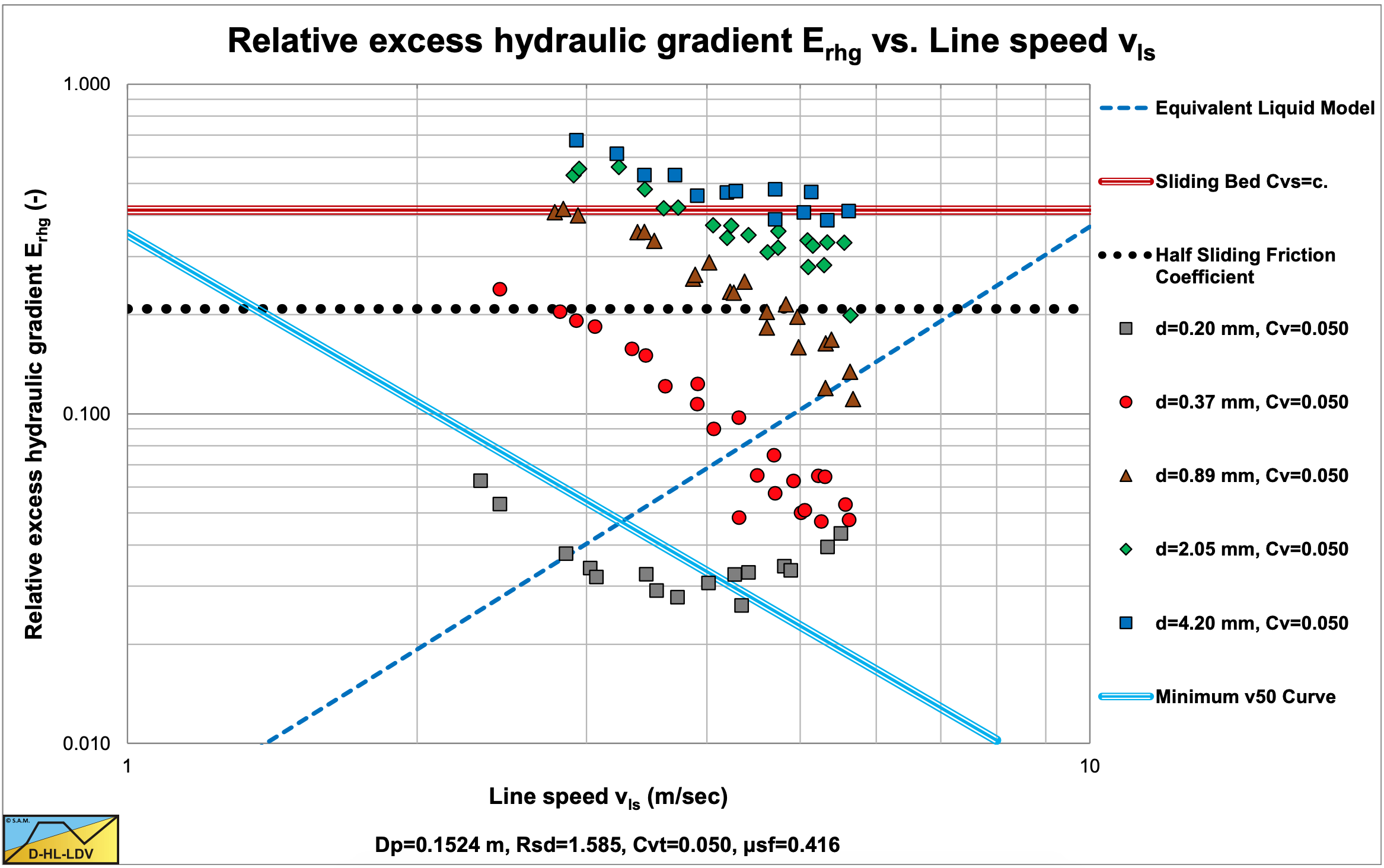

Figure 6.20-23 shows data of Durand & Condolios (1952) in the relative excess hydraulic gradient versus the line speed graph. The advantage of this graph is that it show the solids effect in a double logarithmic graph, where curved line become straight lines. The graph also contains the horizontal sliding bed curve (dark brown solid line), the 50% sliding bed curve (black dots), the ELM curve (dashed dark blue line) and the minimum v50 curve (light blue solid line). The intersection line speed of the data series (extrapolated) with the 50% sliding bed curve, the v50, increases with increasing particle diameter. The question is how does it increase?

Based on the assumption that Wilson et al. (1992) developed a model for operation conditions, meaning for operational line speeds. Usually this means line speeds above the Limit Deposit Velocity, or slightly below. In the case considered, see Figure 6.20-23, this gives line speeds of about 2.5 m/s up to 5.5 m/s. Now 3 cases can be considered:

- Fine particles, d<0.0002 mm.

- Medium particles, 0.0002<d<1 mm.

- Coarse particles, d>1 mm.

Fine particles are assumed to be transport according to the homogeneous flow regime under operational conditions. So there is a minimum v50 for particles with a diameter smaller than d=0.0002 mm. The resulting minimum curve is shown in Figure 6.20-23 (the solid light blue curve). This curve is close to the data of the d=0.0002 mm particles. Since Wilson et al. (1992) used different data to calibrate their model, the match is not exactly. This minimum v50 can be determined by:

\[\ \mathrm{v}_{50, \min }=2.7 \cdot\left(\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3} \cdot \sqrt{\frac{\mathrm{8}}{\lambda_{\mathrm{l}}}} \quad\text{ or }\quad \mathrm{v}_{50, \min }=\frac{1}{\mu_{\mathrm{sf}}} \cdot\left(\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3} \cdot \sqrt{\frac{\mathrm{8}}{\lambda_{\mathrm{l}}}}\]

For medium sized particles, the v50 is increasing. Figure 6.20-23 shows this increase for particles with d=0.37 mm and d=0.89 mm. Wilson et al. (1992) assumed this increase is proportional to the terminal settling velocity vt. This gives:

\[\ \mathrm{v}_{50}=\left(0.9 \cdot \mathrm{v}_{\mathrm{t}}+2.7 \cdot\left(\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3}\right) \cdot \sqrt{\frac{8}{\lambda_{\mathrm{l}}}}\quad\text{ or }\quad\mathrm{v}_{50}=\left(0.9 \cdot \mathrm{v}_{\mathrm{t}}+\frac{1}{\mu_{\mathrm{sf}}} \cdot\left(\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3}\right) \cdot \sqrt{\frac{8}{\lambda_{\mathrm{l}}}}\]

For coarse particles, the steepness of the decrease of the Erhg parameter with increasing line speed vls is less than for medium particles. In fact it looks like the larger the particle, the less steep the decrease, where very coarse particles could result in an almost horizontal curve. This also means that the intersection line speed of the extrapolated data points with the 50% sliding bed curve is more far away. A horizontal curve has an intersection v50 at infinity. Wilson et al. (1992) took this behavior into account by adding a term with the particle diameter to pipe diameter ratio, according to:

\[\ \mathrm{v}_{50}=\left(0.9 \cdot \mathrm{v}_{\mathrm{t}}+2.7 \cdot\left(\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3}\right) \cdot \sqrt{\frac{8}{\lambda_{\mathrm{l}}}} \cdot \cosh \left(\frac{\mathrm{6 0} \cdot \mathrm{d}_{50}}{\mathrm{D}_{\mathrm{p}}}\right)\]

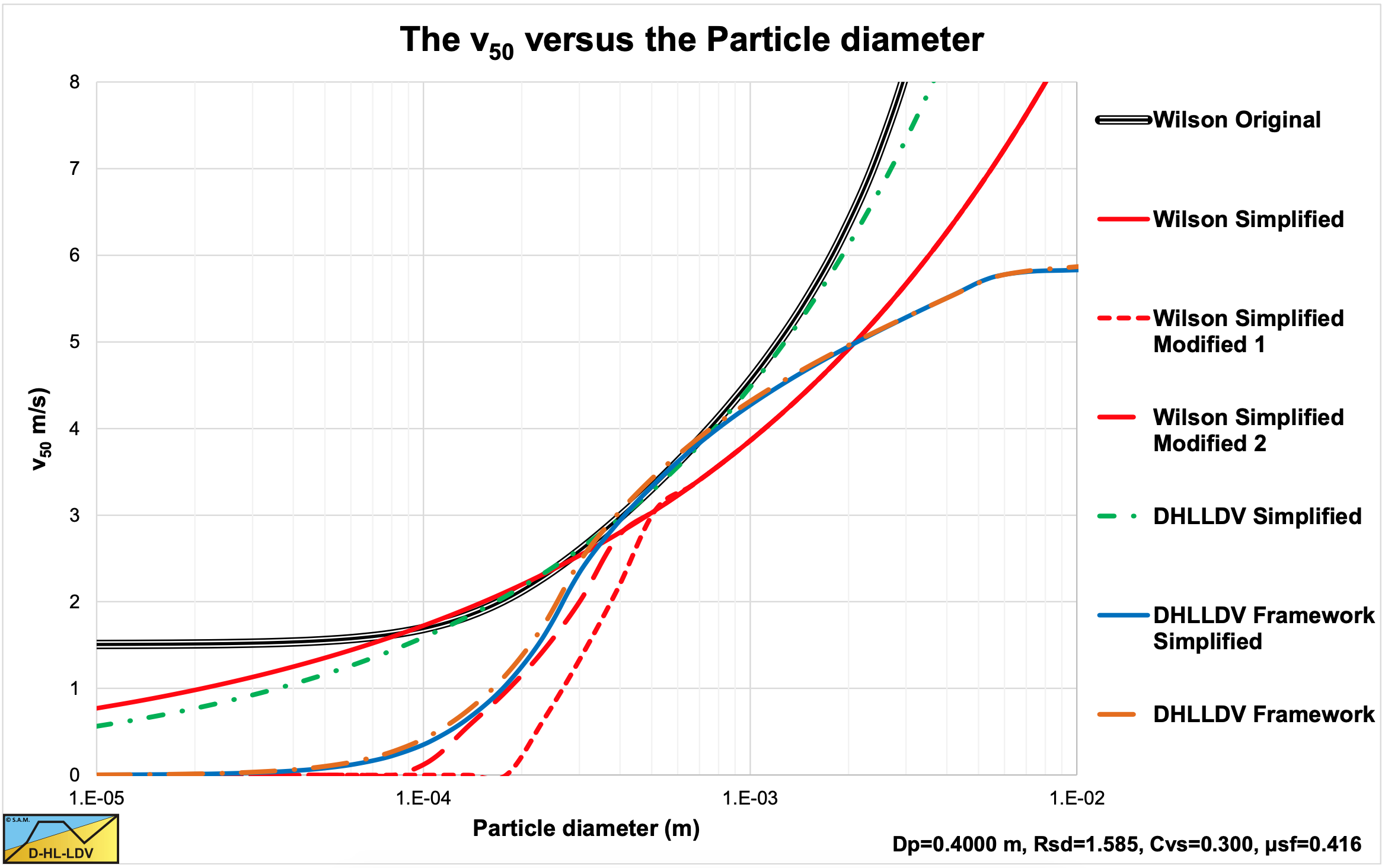

The Darcy Weisbach friction coefficient λl indirectly gives the influence of the pipe diameter. The cosh term gives the influence of the particle diameter to pipe diameter ratio. Figure 6.20-24 shows the resulting v50 curve for a Dp=0.1524 m pipe (6 inch) (the thick black solid line).

\[\ \mathrm{E}_{\mathrm{r h g}}=\mathrm{R}=\frac{\mathrm{i}_{\mathrm{m}}-\mathrm{i}_{\mathrm{l}}}{\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v}}}=\frac{\Delta \mathrm{p}_{\mathrm{m}}-\Delta \mathrm{p}_{\mathrm{l}}}{\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v}}}=\frac{\mu_{\mathrm{s f}}}{\mathrm{2}} \cdot\left(\frac{\mathrm{v}_{\mathrm{5 0}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{M}}\]

For uniform sands Wilson et al. (1992) found a power M=1.7 in the above equation, which works well for medium sands, however for the coarser sands the effect of the cosh term in the v50 should be accompanied by a decrease of this power as follows from the data in Figure 6.20-23. Durand & Condolios (1952) found that for coarse particles the hydraulic gradient and thus the Erhg parameter does not really increase, based on the particle Froude number. The definition of coarse is related to the pipe diameter by Wilson et al. (1992) being d=0.015·Dp or d=Dp/60. This gives for the v50:

\[\ \mathrm{v}_{50^{*}}=\left(0.9 \cdot \mathrm{v}_{\mathrm{t}^{*}}+2.7 \cdot\left(\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{g} \cdot v_{\mathrm{l}}\right)^{1 / 3}\right) \cdot \sqrt{\frac{8}{\lambda_{\mathrm{l}}}} \cdot \cosh (1)\]

The line speed where the heterogeneous curve intersects with the sliding bed curve is about:

\[\ \mathrm{v}_{\mathrm{l s}^{*}}=\frac{\mathrm{2}}{\mathrm{3}} \cdot \mathrm{v}_{\mathrm{5 0}^{*}}\]

Now assume this line speed is a constant, given a certain pipe diameter, the power M for particles of d>0.015.Dp is:

\[\ \mathrm{M}=\frac{\ln (2)}{\ln \left(\frac{3}{2} \cdot \frac{\mathrm{v}_{50}}{\mathrm{v}_{50^{*}}}\right)}\]

In these equations the * is used for the particle diameter d>0.015·Dp. This approach leads to a continuous behavior of the heterogeneous flow regime.

Wilson et al. (1992) simplified the v50 equation to:

\[\ \mathrm{v}_{\mathrm{5 0}} \approx \mathrm{3 . 9 3} \cdot\left(\frac{\mathrm{d}_{\mathrm{5 0}}}{\mathrm{0 . 0 0 1}}\right)^{\mathrm{0 . 3 5}} \cdot\left(\frac{\mathrm{R}_{\mathrm{s d}}}{\mathrm{1.65}}\right)^{\mathrm{0 . 4 5}} \cdot\left(\frac{v_{\mathrm{l}, \mathrm{a c t u a l}}}{v_{\mathrm{w}, \mathrm{2 0}}}\right)^{-\mathrm{0 . 2 5}}\]

Giving a v50 of 3.93 m/s for a 1 mm sand particle in 20o water. This simplified equation is also shown in Figure 6.20-24 (the solid red line). This equation does not contain the influence of the pipe diameter and only approaches the original equation for medium sands. Later the simplified equation has been adjusted for particles with diameters from 0.2 mm to 0.5 mm with a factor:

\[\ \mathrm{f=\frac{d_{h}-0.0002}{0.0005-0.0002}}\]

This is also shown in Figure 6.20-24 as the Wilson simplified modified curve (dashed red line). Where the original equation seems to overestimate the solids effect of fine particles, this modification seems to underestimate the solids effect.

Figure 6.20-24, Figure 6.20-25 and Figure 6.20-26 show the original v50 method, the simplified and the simplified modified equations. The effect of not having the pipe diameter influence in the simplified and the simplified modified equations results in a deviation of these equations with the original method for large diameter pipes.

A better simplification of the v50 is achieved with the following equation (DHLLDV simplified, the solid green line):

\[\ \mathrm{v}_{\mathrm{5 0}} \approx \mathrm{3} \cdot\left(\frac{\mathrm{d}_{\mathrm{5 0}}}{\mathrm{0 .0 0 0 5}}\right)^{\mathrm{0 .4 5}} \cdot\left(\frac{\mathrm{R}_{\mathrm{s d}}}{\mathrm{1 .6 5}}\right)^{\mathrm{0 .4 5}} \cdot\left(\frac{\mathrm{v}_{\mathrm{l}, \mathrm{a c t u a l}}}{v_{\mathrm{w}, \mathrm{2 0}}}\right)^{-\mathrm{0 .2 5}} \cdot\left(\frac{\mathrm{D}_{\mathrm{p}}}{\mathrm{0 .1 5 2 4}}\right)^{\mathrm{0 . 0 9 2}}\]

Figure 6.20-24, Figure 6.20-25 and Figure 6.20-26 show this equation as well. For a Dp=0.1524 m (6 inch) pipe, this equation gives an almost identical v50 compared to the original method for particle diameters in the range of 0.1 to 0.8 mm. For the Dp=0.4 m pipe this range is larger, from 0.1 to 2 mm. For the Dp=1.2 m the range is even larger than for the Dp=0.4 m pipe, the approximation is valid for particles with a diameter from 0.1 mm and above. Still the overestimation of the v50 for small particles remains, as a result of the original assumption of Wilson that there is a minimum v50. Figure 6.20-35 shows that also particles with a diameter smaller than 0.1 mm show heterogeneous behavior with a v50 much smaller than this minimum v50. The correction with equation (6.20-75) seems too drastic and not at the right location. The following correction factor in the range of particle diameters from 0.1 to 0.3 mm seems more appropriate and approaches the DHLLDV curves closely.

\[\ \mathrm{f}=\frac{\mathrm{d}_{\mathrm{h}}-\mathrm{0 . 0 0 0 1}}{\mathrm{0 .0 0 0 4 - 0 . 0 0 0 1}}\]

A better approach of the v50 however is the following equation, based on the DHLLDV Framework:

| \[\ \mathrm{v}_{50} \approx 3.4 \cdot\left(\frac{\mathrm{v}_{\mathrm{t}}}{\sqrt{\mathrm{g} \cdot \mathrm{d}}}\right)^{1.96} \cdot\left(\frac{\mathrm{D}_{\mathrm{p}}}{\mathrm{0 .1 5 2 4}}\right)^{0.092} \cdot\left(\frac{\mathrm{R}_{\mathrm{s d}}}{\mathrm{1 .6 5}}\right)^{-\mathrm{0 . 0 9 2}} \cdot\left(\frac{v_{\mathrm{l}, \mathrm{a c t u a l}}}{v_{\mathrm{w}, \mathrm{2 0}}}\right)^{0.27}\] |

Figure 6.20-24, Figure 6.20-25 and Figure 6.20-26 show the results of this equation and also the results of the much more complicated DHLLDV Framework. In the range of particle diameters of 0.3 to 1 mm, this equation matches the original Wilson method very closely. Above 1 mm the original Wilson method goes to infinity (because of the decreasing power M), while the DHLLDV simplified equation goes to a constant value (assuming the power M does not change) matching the findings of Durand & Condolios (1952). For particles with a diameter smaller than 0.3 mm this equation matches many experimental data and solves the problem of overestimation of the original Wilson method in a more structural way.

6.20.2.5 Conclusions & Discussion

The basic form of the equation for heterogeneous transport, equation (6.20-51), is of the type; hydraulic gradient mixture equals hydraulic gradient carrier liquid + solids effect. This implies that the hydraulic gradient of the carrier liquid and the solids effect are independent like in the Fuhrboter (1961) model. This in contrary with the Durand & Condolios (1952), Newitt et al. (1955) and the Jufin & Lopatin (1966) models. These are of the type; hydraulic gradient mixture equals hydraulic gradient carrier liquid times 1 + solids effect. Equations (6.20-65) and (6.20-66) show the Wilson equation for both types, with correct dimensions.

Basically the model shows straight lines in the Erhg(il) graph with the v50, 0.22 point as a pivot point. Depending on the value of the power M, the straight line pivots around this point. Figure 6.20-21 shows these straight line for powers of 0.25, 1.0 and 1.7. The power of 1.7 for uniform sands matches very well with the DHLLDV Framework for uniform sands.

The model gives good results if the physics on which it is based occur, medium sized particles. For very fine particles in a large pipe there will never be a sliding bed. The stationary bed will vaporize (erode) with increasing line speed, probably without sheet flow, see Figure 6.20-20. The 50% stratification criterion is not valid here because the sliding friction is not 100% mobilized resulting in a much lower friction. Very large particles will, almost always, be more than 50% stratified, resulting in a sliding bed or sliding flow, so the model is also invalid in this case, see Figure 6.20-22.

The DHLLDV simplified equation gives a much better approximation of the v50 parameter and solved a number of shortcomings.

Wilson et al. (2006) suggests the following equation for full stratified flow, based on μsf=0.4 (or 0.44):

\[\ \begin{array}{rl}\mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}}+\mathrm{C}_{\mathrm{v} \mathrm{t}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \mathrm{2} \cdot \mathrm{\mu}_{\mathrm{s f}} \cdot\left(\frac{\mathrm{4} \cdot \mathrm{v}_{\mathrm{s m}}}{\mathrm{3} \cdot \mathrm{v}_{\mathrm{l} \mathrm{s}}}\right)^{\mathrm{0 . 2 5}} & \mathrm{o r} \quad \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}}+\mathrm{C}_{\mathrm{v t}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{0 . 2 5}} \\ \text { Based on } \mu_{\mathrm{s f}}=\mathrm{0 . 4 0}\quad\quad\quad\quad & \quad\quad\quad\quad\text{ Based on } \mu_{\mathrm{s f}}=\mathrm{0 . 4 4}\end{array}\]

As is shown in Figure 6.20-22 there will be a discontinuity jumping from the heterogeneous model to the full stratified model, even if the same power of 0.25 is applied. In fact if more than 50% of the solids is stratified, the v50 point at Erhg=0.22 in the 3 graphs will never be reached.

In a number of papers the fully stratified flow term is reduced to 50% or even 25%, so it is not really clear what to use. Assuming a full sliding bed at the Limit of Stationary Deposity Velocity, the equation should be for the constant spatial volumetric case and based on the weight approach:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}}+\mathrm{C}_{\mathrm{v s}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{0 . 2 5}}\]

For the constant delivered volumetric case this gives:

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{l}}+\frac{\mathrm{C}_{\mathrm{v s}}\left(\mathrm{v}_{\mathrm{s m}}\right)}{\mathrm{C}_{\mathrm{vt}}} \cdot \mathrm{C}_{\mathrm{v t}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l} \mathrm{s}}}\right)^{\mathrm{0 . 2 5}}\]

Where the spatial concentration at the LSDV depends on the line speed and other parameters, but is always larger than 1.

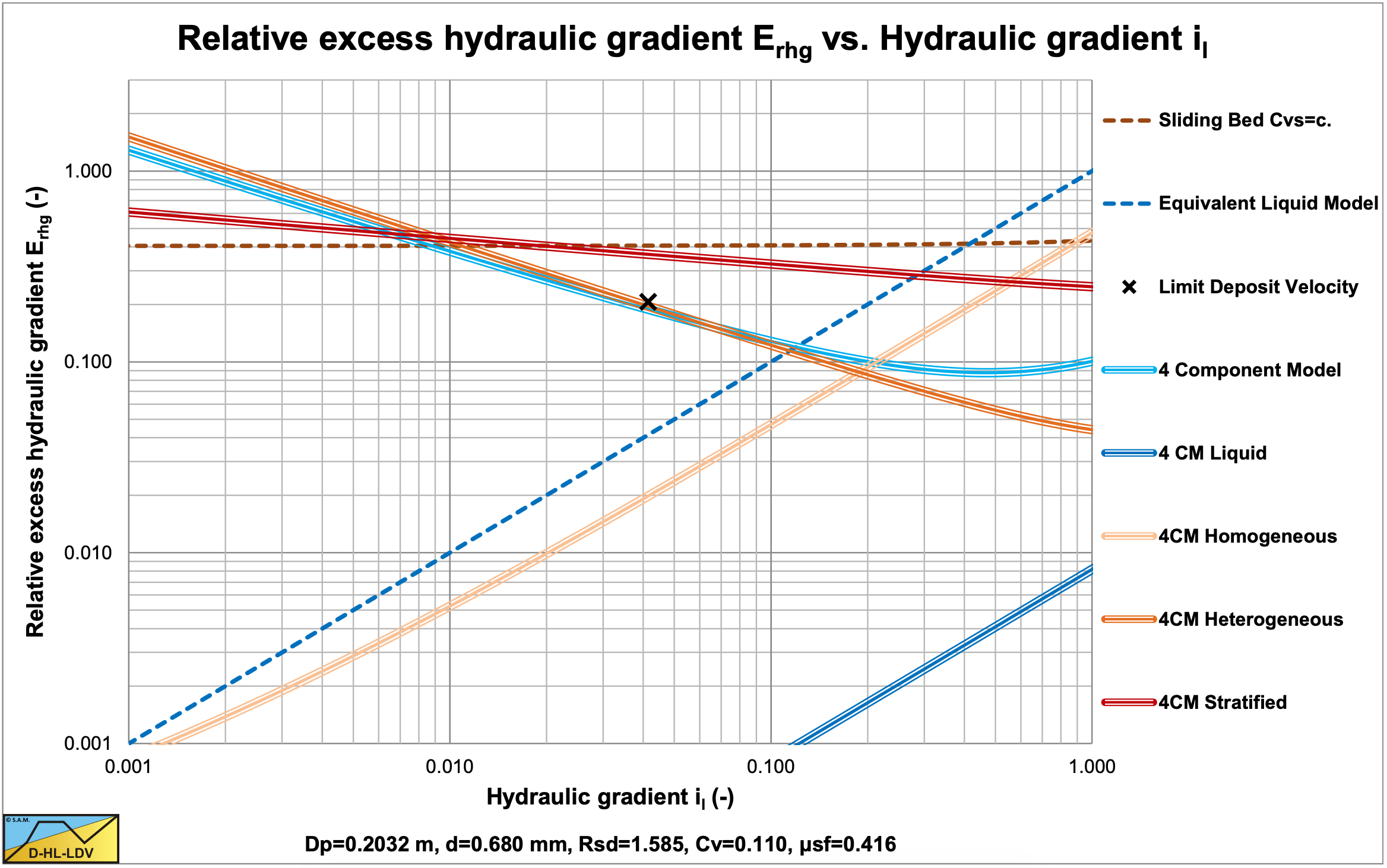

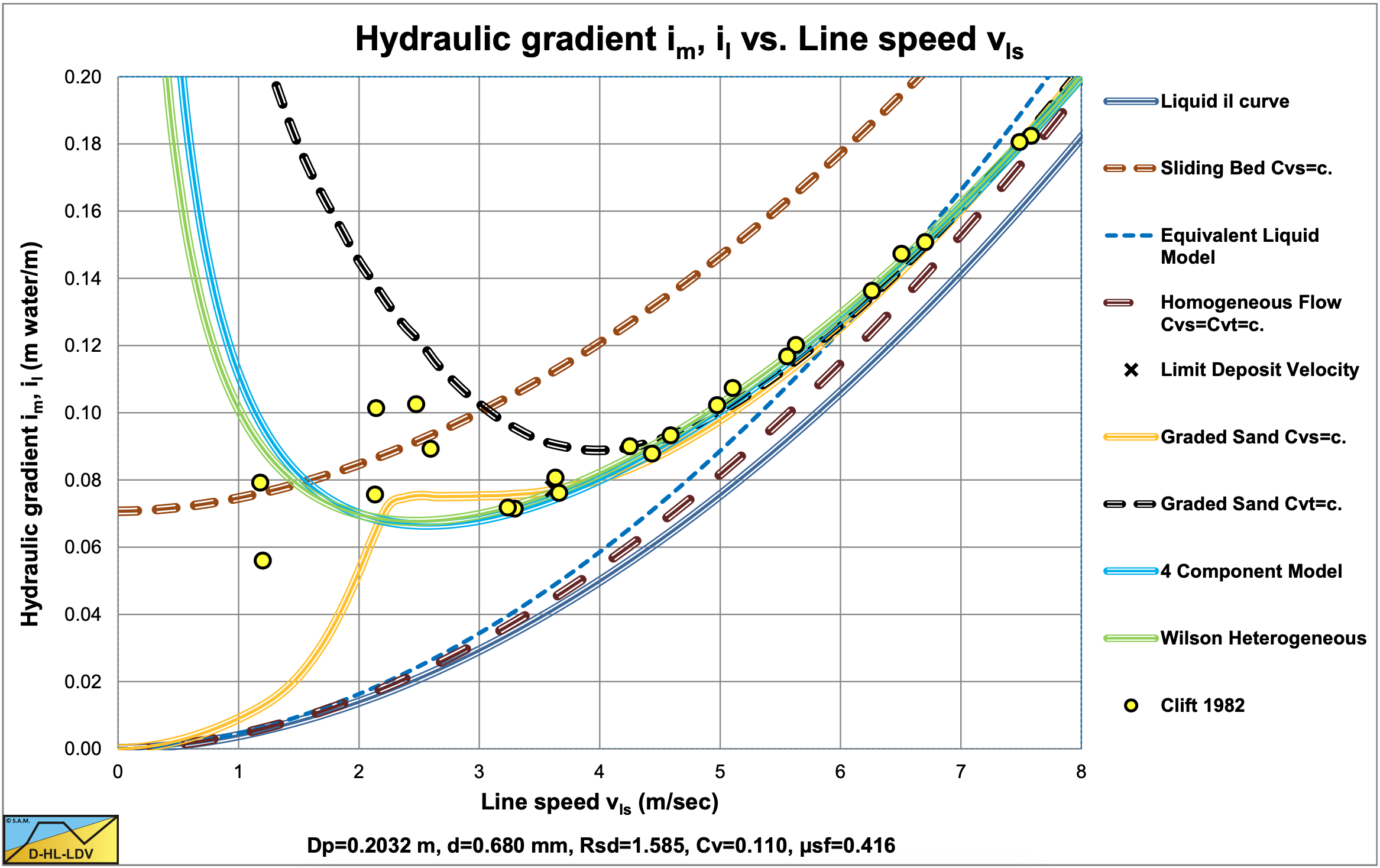

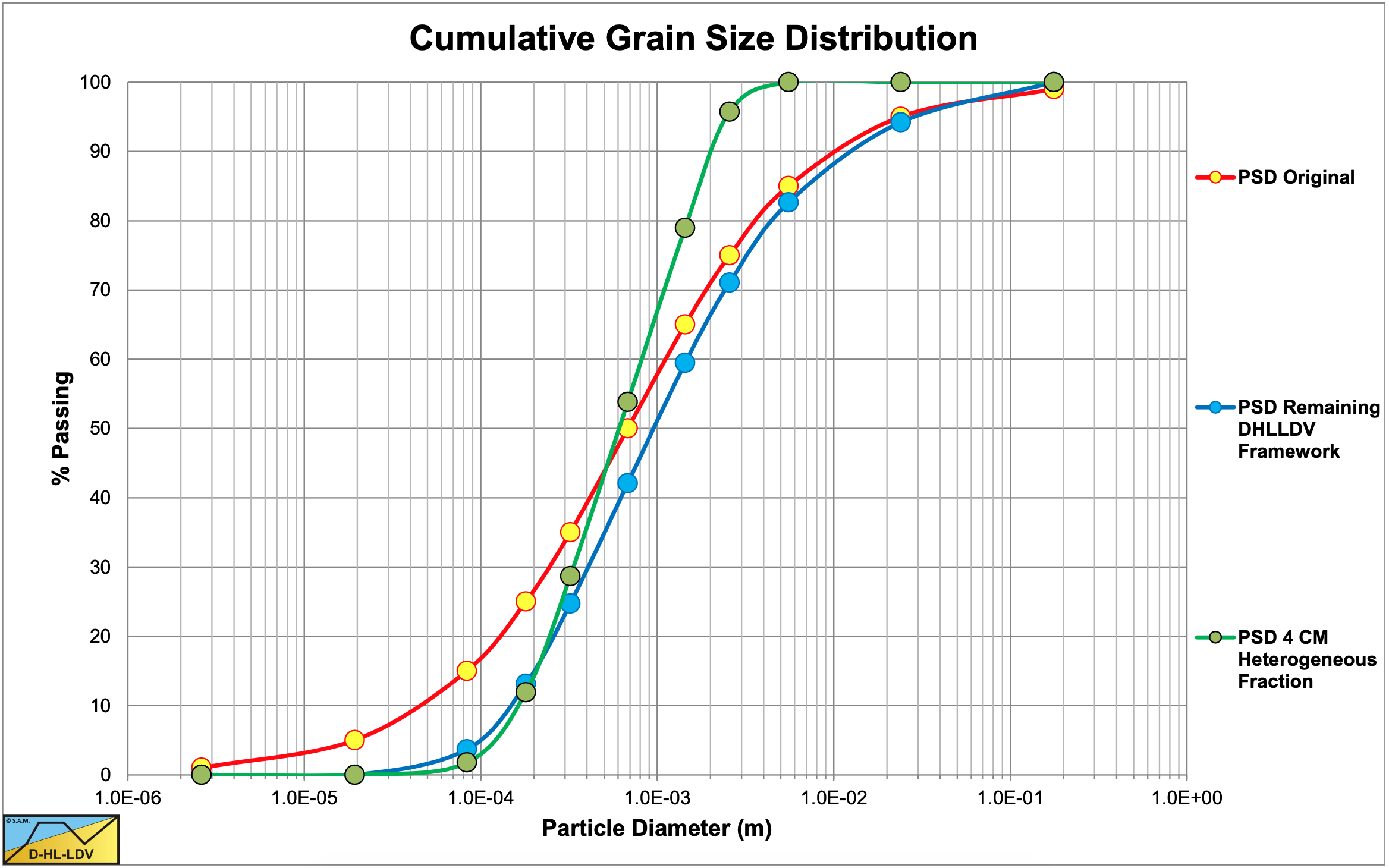

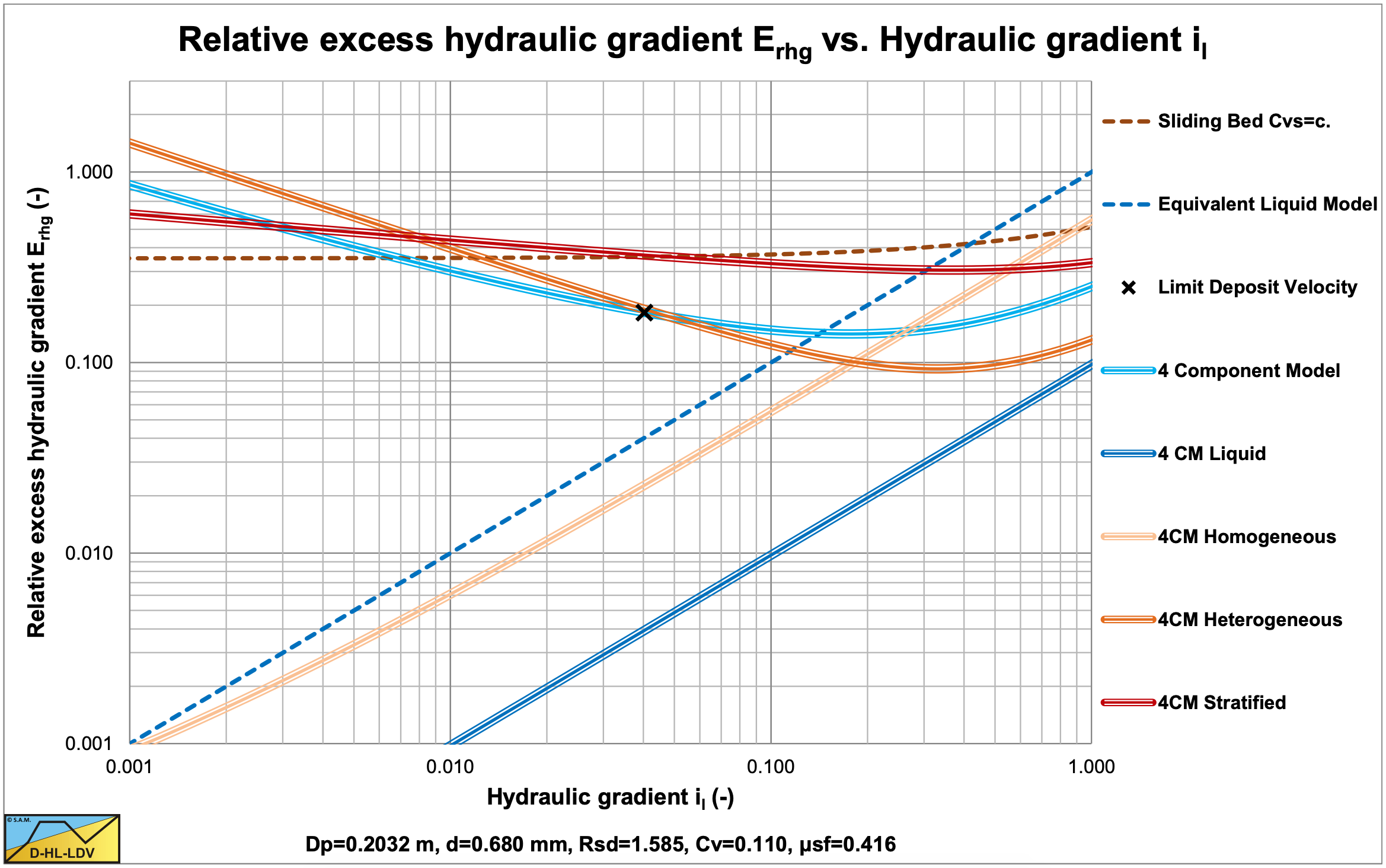

6.20.3 The 4 Component Model of Wilson & Sellgren (2001)

6.20.3.1 Introduction

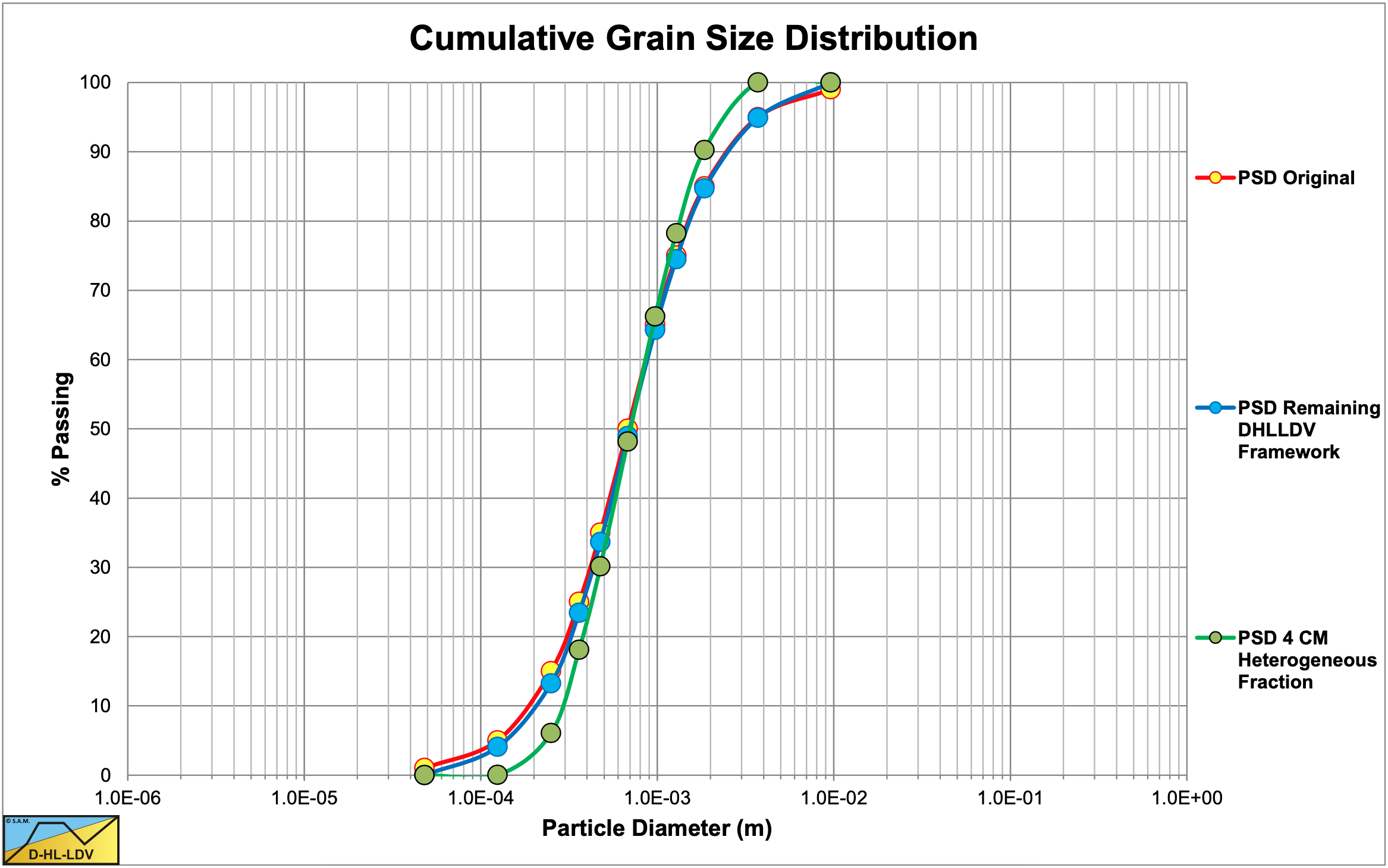

Broad particle grading mean that several of the normally considered slurry flow regimes are included. A pipeline slurry friction loss model consisting of three regimes was initially proposed by K.C. Wilson in (2001), then extended to a four components consisting of fluid, pseudo-homogeneous, heterogeneous and fully stratified components, Wilson et al. (2006). It was successively developed and validated for a variety of experimental data covering volumetric solids concentrations of up to nearly 40% and particle sizes of up to 65mm, Sellgren and Wilson (2007).

Four components are distinguished:

- Homogeneous flow (uses the index f), the fraction d<0.04 mm.

- Pseudo homogeneous flow (uses the index ph), the fraction 0.04 mm<d<0.2·\(\ v_r \) mm.

- Heterogeneous flow (uses the index h), the fraction 0.2·νr mm<d<0.015·Dp.

- Stratified flow (uses the index s), d>0.015·Dp.

The relative kinematic viscosity \(\ v_r \) is the ratio of the kinematic viscosity of the carrier fluid to that of water at 20°C.

The sum of the 4 fractions always has to be equal to unity.

\[\ \mathrm{X}_{\mathrm{f}}+\mathrm{X}_{\mathrm{p h}}+\mathrm{X}_{\mathrm{h}}+\mathrm{X}_{\mathrm{s}}=\mathrm{1}\]

The total delivered volumetric concentration is the sum of the concentrations of the 4 fractions.

\[\ \mathrm{C}_{\mathrm{v t}}=\mathrm{C}_{\mathrm{v t}, \mathrm{f}}+\mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{p h}}+\mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{h}}+\mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{s}}=\mathrm{X}_{\mathrm{f}} \cdot \mathrm{C}_{\mathrm{v t}}+\mathrm{X}_{\mathrm{p h}} \cdot \mathrm{C}_{\mathrm{v t}}+\mathrm{X}_{\mathrm{h}} \cdot \mathrm{C}_{\mathrm{v t}}+\mathrm{X}_{\mathrm{s}} \cdot \mathrm{C}_{\mathrm{vt}}\]

The total hydraulic gradient of the mixture is the sum of the hydraulic (excess) gradients of the 4 fractions.

\[\ \mathrm{i}_{\mathrm{m}}=\mathrm{i}_{\mathrm{f}}+\Delta \mathrm{i}_{\mathrm{p h}}+\Delta \mathrm{i}_{\mathrm{h}}+\Delta \mathrm{i}_{\mathrm{s}} \quad\text{ in }\quad(\mathrm{m} \text { carrier liquid/m pipe })\]

6.20.3.2 The Homogeneous or Equivalent Fluid Fraction

In the homogeneous phase, the spatial and transport volumetric concentrations are assumed to be equal.

\[\ \mathrm{C}_{\mathrm{v s}, \mathrm{f}}=\mathrm{C}_{\mathrm{v t}, \mathrm{f}}\]

Thomas (1965) derived an equation to determine the effective viscosity μf as a function of the concentration Cvs,f of the particles in the mixture:

\[\ \mu_{\mathrm{f}}=\mu_{\mathrm{l}} \cdot\left(1+2.5 \cdot \mathrm{C}_{\mathrm{vs}, \mathrm{f}}+10.05 \cdot \mathrm{C}_{\mathrm{vs}, \mathrm{f}}^{2}+0.00273 \cdot \mathrm{e}^{16.6 \cdot \mathrm{C}_{\mathrm{vs}, \mathrm{f}}}\right) \quad\text{ with: }\quad \mu_{\mathrm{r}}=\mu_{\mathrm{f}} / \mu_{\mathrm{l}}\]

The fluid density ρf equals the carrier liquid density ρl plus the additional density of the homogeneous fraction of the PSD, according to Wilson et al. (2006) the fraction smaller than 0.04 mm.

\[\ \rho_{\mathrm{f}}=\rho_{\mathrm{l}} \cdot\left(1+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{f}}\right) \quad\text{ and }\quad v_{\mathrm{f}}=\frac{\mu_{\mathrm{f}}}{\rho_{\mathrm{f}}}\]

This results in modified fluid properties compared with the carrier liquid, which will be used for all the flow regimes. The hydraulic gradient of the homogeneous flow regime if is now:

\[\ \mathrm{i}_{\mathrm{l}}=\frac{\lambda_{\mathrm{f}} \cdot \mathrm{v}_{\mathrm{l s}}^{2}}{2 \cdot \mathrm{g} \cdot \mathrm{D}_{\mathrm{p}}} \Rightarrow \mathrm{i}_{\mathrm{f}}=\frac{\Delta \mathrm{p}_{\mathrm{f}}}{\rho_{\mathrm{l}} \cdot \mathrm{g} \cdot \Delta \mathrm{L}}=\frac{\rho_{\mathrm{f}}}{\rho_{\mathrm{l}}} \cdot \frac{\lambda_{\mathrm{f}} \cdot \mathrm{v}_{\mathrm{l} \mathrm{s}}^{2}}{\mathrm{2} \cdot \mathrm{g} \cdot \mathrm{D}_{\mathrm{p}}}=\frac{\rho_{\mathrm{f}}}{\rho_{\mathrm{l}}} \cdot \mathrm{i}_{\mathrm{l}} \quad\text{ with: }\quad \Delta \mathrm{p}_{\mathrm{f}}=\lambda_{\mathrm{f}} \cdot \frac{\Delta \mathrm{L}}{\mathrm{D}_{\mathrm{p}}} \cdot \frac{1}{2} \cdot \rho_{\mathrm{f}} \cdot \mathrm{v}_{\mathrm{ls}}^{\mathrm{2}}\]

The Darcy Weisbach friction factor λf is determined based on these fluid properties. The Darcy Weisbach friction factor will not differ much from the Darcy Weisbach friction factor resulting from the carrier liquid properties.

6.20.3.3 The Pseudo Homogeneous Fraction

In the pseudo homogeneous phase, the spatial and transport volumetric concentrations are also assumed to be equal.

\[\ \mathrm{C_{v s, p h}=C_{v t, p h}}\]

The hydraulic gradient Δiph is determined with the ELM model without adjusting the effective viscosity according to:

\[\ \Delta \mathrm{i}_{\mathrm{ph}}=\mathrm{C}_{\mathrm{vs}, \mathrm{ph}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f}}}{\rho_{\mathrm{f}}}\right) \cdot \mathrm{i}_{\mathrm{f}}=\mathrm{C}_{\mathrm{vs}, \mathrm{ph}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f}}}{\rho_{\mathrm{f}}}\right) \cdot \frac{\rho_{\mathrm{f}}}{\rho_{\mathrm{l}}} \cdot \mathrm{i}_{\mathrm{l}}=\mathrm{C}_{\mathrm{vs}, \mathrm{ph}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f}}}{\rho_{\mathrm{l}}}\right) \cdot \mathrm{i}_{\mathrm{l}}\]

The resulting density ρfp for the next flow regime is:

\[\ \rho_{\mathrm{fp}}=\rho_{\mathrm{l}} \cdot\left(1+\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{f}}+\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{p h}}\right)\]

The fluid viscosity is not adjusted for the density or concentration in this fraction.

6.20.3.4 The Heterogeneous Fraction

The original Wilson et al. (2006) heterogeneous model is based on a velocity v50, where 50% of the solids are stratified and the other 50% in suspension. The simplified equation to determine this v50 is:

\[\ \mathrm{v}_{\mathrm{5 0}} \approx \mathrm{3 .9 3} \cdot\left(\mathrm{1 0 0 0} \cdot \mathrm{d}_{\mathrm{5 0}}\right)^{\mathrm{0 . 3 5}} \cdot\left(\frac{\mathrm{R}_{\mathrm{s d}}}{\mathrm{1 .6 5}}\right)^{\mathrm{0 . 4 5}} \cdot\left(\frac{v_{\mathrm{f}}}{v_{\mathrm{l}, \mathrm{2} 0}}\right)^{-\mathrm{0 . 2 5}}\]

The original equation to determine the excess hydraulic gradient is:

\[\ \Delta \mathrm{i}_{\mathrm{h}}=\mathrm{C}_{\mathrm{v} \mathrm{t}} \cdot \mathrm{R}_{\mathrm{s} \mathrm{d}} \cdot \frac{\boldsymbol{\mu}_{\mathrm{s} \mathrm{f}}}{\mathrm{2}} \cdot\left(\frac{\mathrm{v}_{\mathrm{5 0}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{M}}\]

The equation for v50 now has to be adjusted for an average particle diameter of the heterogeneous fraction dh and for the relative submerged density according to:

\[\ \begin{array}{left} \mathrm{v}_{\mathrm{5 0}} \approx \mathrm{3.93} \cdot\left(\mathrm{1 0 0 0} \cdot \mathrm{d}_{\mathrm{h}}\right)^{\mathrm{0 . 3 5}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f p}}}{\rho_{\mathrm{l}}} \cdot \frac{\mathrm{1}}{\mathrm{1 . 6 5}}\right)^{\mathrm{0 .4 5}} \cdot v_{\mathrm{r}}^{-\mathrm{0 . 2 5}}\\

\mathrm{d}_{\mathrm{h}}=\frac{\left(\mathrm{0 . 0 0 0 2} \cdot v_{\mathrm{r}}+\mathrm{M i n}\left(\mathrm{0 . 0 1 5} \cdot \mathrm{D}_{\mathrm{p}}, \mathrm{d}_{\mathrm{m a x}}\right)\right)}{\mathrm{2}}\end{array}\]

The excess hydraulic gradient Δih can now be determined according to, where M is taken as unity:

\[\ \begin{array}\Delta \mathrm{i}_{\mathrm{h}}=\frac{\rho_{\mathrm{f p}}}{\rho_{\mathrm{l}}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{h}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f p}}}{\rho_{\mathrm{f p}}}\right) \cdot \frac{\mu_{\mathrm{s} \mathrm{f}}}{2} \cdot\left(\frac{\mathrm{v}_{\mathrm{5} 0}}{\mathrm{v}_{\mathrm{ls}}}\right)^{\mathrm{M}}\\

\mathrm{O} \mathrm{r}\\

\Delta \mathrm{i}_{\mathrm{h}}=\frac{\rho_{\mathrm{f p}}}{\rho_{\mathrm{l}}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{h}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f p}}}{\rho_{\mathrm{f p}}}\right) \cdot \frac{\mu_{\mathrm{s f}}}{2} \cdot\left(\frac{\mathrm{v}_{\mathrm{5} 0}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{M}} \cdot \frac{\mathrm{d}_{\mathrm{h}}-\mathrm{0 . 0 0 0 2}}{\mathrm{0 . 0 0 0 5 - 0 . 0 0 0 2}} \quad\text{ for }\quad \mathrm{0 . 0 0 0 2 < d}_{\mathrm{h}}<\mathrm{0 . 0 0 0 5}\end{array}\]

The resulting density for the next flow regime is:

\[\ \rho_{\mathrm{fph}}=\rho_{\mathrm{l}} \cdot\left(1+\mathrm{R}_{\mathrm{sd}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{f}}+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{p h}}+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{h}}\right)\]

6.20.3.5 The Fully Stratified Fraction

In the original model of Wilson et al. (2006) the maximum limit of stationary deposit velocity vsm can be estimated by:

\[\ \mathrm{v}_{\mathrm{sm}}=\frac{\mathrm{8.8} \cdot\left(\frac{\mu_{\mathrm{sf}} \cdot \mathrm{R}_{\mathrm{sd}}}{\mathrm{0.66}}\right)^{0.55} \cdot \mathrm{D}_{\mathrm{p}}^{0.7} \cdot \mathrm{d}^{\mathrm{1 . 7 5}}}{\mathrm{d}^{2}+\mathrm{0.1 1} \cdot \mathrm{D}_{\mathrm{p}}^{0.7}}\]

The original excess hydraulic gradient for a fully stratified flow can be approximated by (for a friction coefficient of 0.4):

\[\ \Delta \mathrm{i}_{\mathrm{s}}=\mathrm{C}_{\mathrm{v t}} \cdot \mathrm{R}_{\mathrm{s d}} \cdot \mathrm{2} \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{0 . 2 5}}\]

Wilson et al. (2006) suggest to multiply this equation by 0.5, adjust the relative submerged density, not to adjust Vsm and of course use the strtified fraction according to:

\[\ \Delta \mathrm{i}_{\mathrm{s}}=\frac{\rho_{\mathrm{fph}}}{\rho_{\mathrm{l}}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{s}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f p h}}}{\rho_{\mathrm{f p h}}}\right) \cdot \mu_{\mathrm{s f}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25}\]

The resulting mixture density is now:

\[\ \rho_{\mathrm{m}}=\rho_{\mathrm{l}} \cdot\left(1+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{f}}+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{p} \mathrm{h}}+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}, \mathrm{h}}+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s , s}}\right)=\rho_{\mathrm{l}} \cdot\left(\mathrm{1}+\mathrm{R}_{\mathrm{s d}} \cdot \mathrm{C}_{\mathrm{v s}}\right)\]

6.20.3.6 The Resulting Equation

The resulting equation of the 4 component model is:

\[\ \begin{aligned} \mathrm{i}_{\mathrm{m}}=& \frac{\rho_{\mathrm{f}}}{\rho_{\mathrm{l}}} \cdot \frac{\lambda_{\mathrm{f}} \cdot \mathrm{v}_{\mathrm{l} \mathrm{s}}^{2}}{\mathrm{2} \cdot \mathrm{g} \cdot \mathrm{D}_{\mathrm{p}}} \cdot\left(\mathrm{1}+\mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{p h}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f}}}{\rho_{\mathrm{f}}}\right)\right)+\frac{\rho_{\mathrm{f p}}}{\rho_{\mathrm{l}}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{h}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f p}}}{\rho_{\mathrm{f p}}}\right) \cdot \frac{\mu_{\mathrm{f f}}}{\mathrm{2}} \cdot\left(\frac{\mathrm{v}_{\mathrm{5} 0}}{\mathrm{v}_{\mathrm{l s}}}\right)^{\mathrm{M}} +\frac{\rho_{\mathrm{fph}}}{\rho_{\mathrm{l}}} \cdot \mathrm{C}_{\mathrm{v} \mathrm{t}, \mathrm{s}} \cdot\left(\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f p h}}}{\rho_{\mathrm{f p h}}}\right) \cdot \mu_{\mathrm{sf}} \cdot\left(\frac{\mathrm{v}_{\mathrm{s m}}}{\mathrm{v}_{\mathrm{l s}}}\right)^{0.25} \end{aligned}\]

The way the different mixture densities are determined is incorrect. For low concentrations the difference is negligible, but for high concentrations it may be significant.

6.20.3.7 Modified 4 Component Model

Analyzing the 4 component model results in a number of issues, which will be addressed here. The first issue is the way the densities of the carrier liquid with the different fractions is calculated. If a sand or gravel is considered with a volumetric concentration Cvs of which a fraction X is in suspension, then the resulting mixture density ρx should be determined based on the volume of carrier liquid and the volume of the fraction X and not on the total volume. So the mixture density ρx times the volume of the carrier liquid (1-Cvs) + the volume of the fraction considered X·Cvs, which is the mass of the mixture, has to be equal to the mass of the carrier liquid ρl·(1-Cvs) + the mass of the solids considered ρs·Cvs·X. This gives the following equation:

\[\ \begin{array}{left} \rho_{\mathrm{x}} \cdot\left(\mathrm{1}-\mathrm{C}_{\mathrm{v s}}+\mathrm{C}_{\mathrm{v s}} \cdot \mathrm{X}\right)=\rho_{\mathrm{l}} \cdot\left(\mathrm{1}-\mathrm{C}_{\mathrm{v s}}\right)+\rho_{\mathrm{s}} \cdot \mathrm{X} \cdot \mathrm{C}_{\mathrm{v s}}\\

\frac{\rho_{\mathrm{x}}}{\rho_{\mathrm{l}}}=\mathrm{S}_{\mathrm{x}}=\frac{\left(1-\mathrm{C}_{\mathrm{v s}}\right)+\mathrm{S}_{\mathrm{s}} \cdot \mathrm{X} \cdot \mathrm{C}_{\mathrm{v} \mathrm{s}}}{\left(1-\mathrm{C}_{\mathrm{v s}}+\mathrm{C}_{\mathrm{v s}} \cdot \mathrm{X}\right)} \quad\text{ with: }\quad \mathrm{S}_{\mathrm{s}}=\frac{\rho_{\mathrm{s}}}{\rho_{\mathrm{l}}}\end{array}\]

This can be written as, with some reorganization and simplification:

\[\ \begin{array}{left} \frac{\rho_{\mathrm{x}}}{\rho_{\mathrm{l}}}=\mathrm{S}_{\mathrm{x}}=\frac{\left(1-\mathrm{C}_{\mathrm{v s}}\right)+\mathrm{S}_{\mathrm{s}} \cdot \mathrm{X} \cdot \mathrm{C}_{\mathrm{v s}}+\mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot \mathrm{X}-\mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot \mathrm{X}}{\left(1-\mathrm{C}_{\mathrm{v} \mathrm{s}}+\mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot \mathrm{X}\right)}\\

\frac{\rho_{\mathrm{x}}}{\rho_{\mathrm{l}}}=\mathrm{S}_{\mathrm{x}}=\frac{\left(1-\mathrm{C}_{\mathrm{v s}}\right)+\mathrm{C}_{\mathrm{v s}} \cdot \mathrm{X}+\mathrm{X} \cdot \mathrm{C}_{\mathrm{vs}} \cdot\left(\mathrm{s}_{\mathrm{s}}-\mathrm{1}\right)}{\left(1-\mathrm{C}_{\mathrm{v s}}+\mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot \mathrm{X}\right)}=1+\frac{\mathrm{X} \cdot \mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot\left(\mathrm{S}_{\mathrm{s}}-1\right)}{\left(1-\mathrm{C}_{\mathrm{v s}}+\mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot \mathrm{X}\right)}\\

\text{If } \mathrm{X}=\mathrm{1} \quad \Rightarrow \quad \frac{\rho_{\mathrm{m}}}{\rho_{\mathrm{l}}}=\mathrm{S}_{\mathrm{m}}=\mathrm{1}+\mathrm{C}_{\mathrm{v} \mathrm{s}} \cdot\left(\mathrm{S}_{\mathrm{s}}-1\right)\end{array}\]

So if all the particles are considered, X=1, the resulting equation reduces to the simple equation also used in the ELM. However if X<>1 equation (6.20-103) gives a different result compared to equation (6.20-87), (6.20-91) and (6.20-96). Using the relative submerged density Rsd this gives:

\[\ \frac{\rho_{\mathrm{x}}}{\rho_{\mathrm{l}}}=\mathrm{S}_{\mathrm{x}}=\mathrm{1}+\frac{\mathrm{X} \cdot \mathrm{C}_{\mathrm{v s}} \cdot \mathrm{R}_{\mathrm{s d}}}{\left(\mathrm{1}-\mathrm{C}_{\mathrm{v s}}+\mathrm{C}_{\mathrm{v s}} \cdot \mathrm{X}\right)}\]

This gives for the relative density Sf of the homogeneous mixture of particles with d<0.000040 m:

\[\ \mathrm{S_{f}=\frac{\rho_{f}}{\rho_{l}}=1+\frac{X_{f} \cdot C_{v s} \cdot R_{s d}}{1-C_{v s} \cdot\left(1-X_{f}\right)}}\]

For the homogeneous and the pseudo homogeneous fraction this gives a relative density of the mixture Sfp for particles with d<0.000200 m (in water):

\[\ \mathrm{ S_{f p}=\frac{\rho_{f p}}{\rho_{l}}=1+\frac{\left(X_{f}+X_{p h}\right) \cdot C_{v s} \cdot R_{s d}}{1-C_{v s} \cdot\left(1-X_{f}-X_{p h}\right)}}\]

Including the heterogeneous fraction, together with the homogeneous and pseudo homogeneous fractions gives a relative density of the mixture Sfph for particles with d<0.015·Dp:

\[\ \mathrm{S_{\mathrm{fph}}=\frac{\rho_{\mathrm{fph}}}{\rho_{\mathrm{l}}}=1+\frac{\left(\mathrm{x}_{\mathrm{f}}+\mathrm{X}_{\mathrm{ph}}+\mathrm{X}_{\mathrm{h}}\right) \cdot \mathrm{C}_{\mathrm{vt}} \cdot \mathrm{R}_{\mathrm{sd}}}{1-\mathrm{C}_{\mathrm{vt}} \cdot\left(1-\mathrm{X}_{\mathrm{f}}-\mathrm{X}_{\mathrm{ph}}-\mathrm{X}_{\mathrm{h}}\right)}}\]

Also including the stratified fraction, results in all the particles giving a relative mixture density of Sfphs=Sm:

\[\ \begin{array}{left}\mathrm{S}_{\mathrm{fphs}}=\frac{\rho_{\mathrm{fphs}}}{\rho_{\mathrm{l}}}=1+\frac{\left(\mathrm{x}_{\mathrm{f}}+\mathrm{X}_{\mathrm{ph}}+\mathrm{X}_{\mathrm{h}}+\mathrm{X}_{\mathrm{s}}\right) \cdot \mathrm{C}_{\mathrm{vt}} \cdot \mathrm{R}_{\mathrm{sd}}}{1-\mathrm{C}_{\mathrm{vt}} \cdot\left(1-\mathrm{X}_{\mathrm{f}}-\mathrm{X}_{\mathrm{ph}}-\mathrm{X}_{\mathrm{h}}-\mathrm{X}_{\mathrm{s}}\right)}=\mathrm{S}_{\mathrm{m}}=\frac{\rho_{\mathrm{m}}}{\rho_{\mathrm{l}}}=1+\mathrm{C}_{\mathrm{vt}} \cdot \mathrm{R}_{\mathrm{sd}}\\

\text{With : }\\

\mathrm{X}_{\mathrm{f}}+\mathrm{X}_{\mathrm{p h}}+\mathrm{X}_{\mathrm{h}}+\mathrm{X}_{\mathrm{s}}=\mathrm{1}\end{array}\]

Now that all the relative densities are known, the hydraulic gradients will be determined, after adjusting the liquid viscosity according to equations (6.20-86) and (6.20-87).

The relative submerged density of particles in the new homogeneous fluid is:

\[\ \mathrm{R}_{\mathrm{s d}, \mathrm{f}}=\frac{\rho_{\mathrm{s}}-\rho_{\mathrm{f}}}{\rho_{\mathrm{f}}}\]

Now for each fraction the hydraulic gradient, based on the carrier liquid density ρl, will be determined as if only that fraction is present in the mixture with a concentration Cvt.

Homogeneous regime:

The hydraulic gradient of the homogeneous flow regime if is now: